Preparation method for molecularly imprinted monolithic column solid-phase microextraction fiber

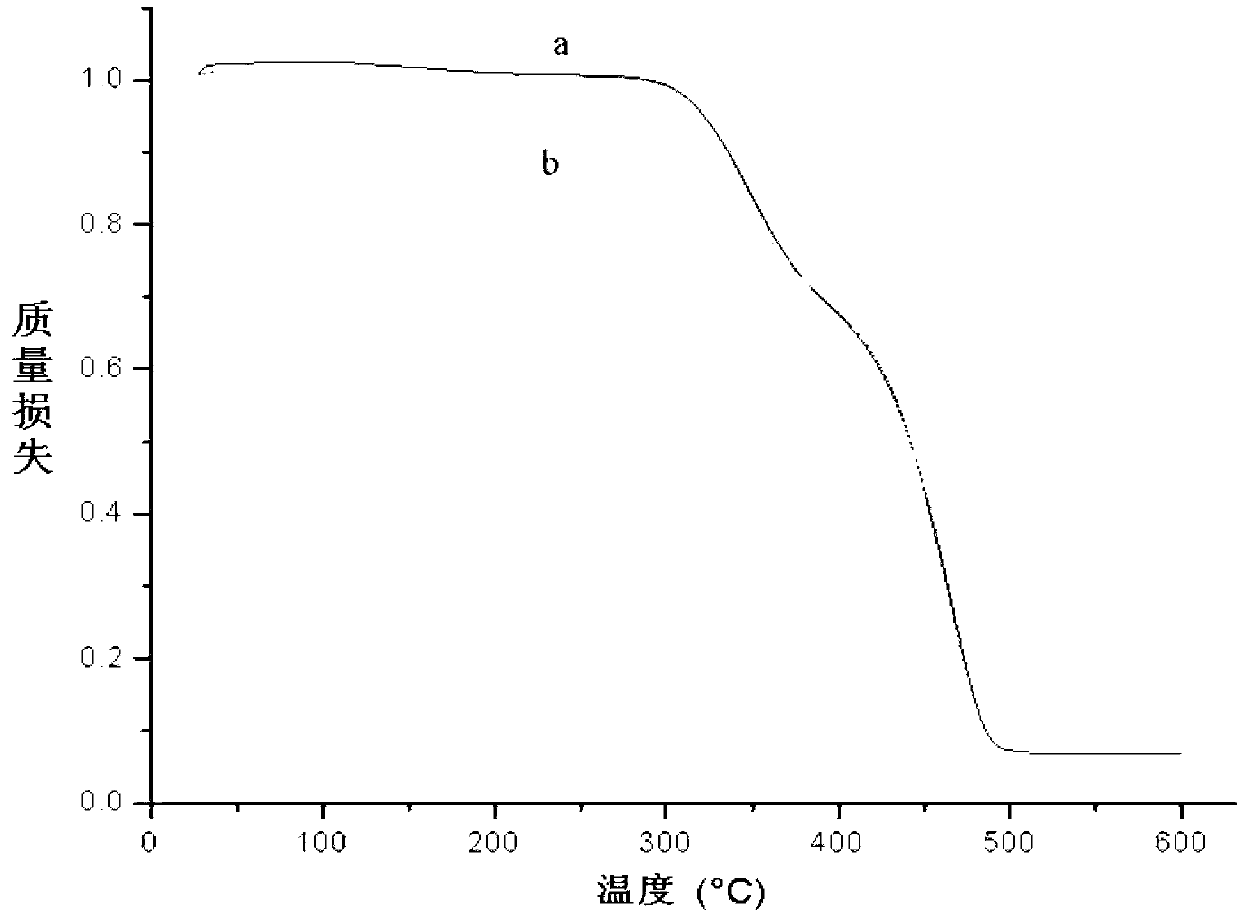

A technology of molecular imprinting and fiber extraction, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to selectively extract target compounds, non-selective graphene coating, etc., and achieve easy control of fiber diameter and high selectivity. the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take a quartz capillary with an inner diameter of 0.53mm and a length of 10cm, wash it with 0.1N sodium hydroxide and hydrochloric acid for 30 minutes, wash it with deionized water until neutral, and dry it with nitrogen.

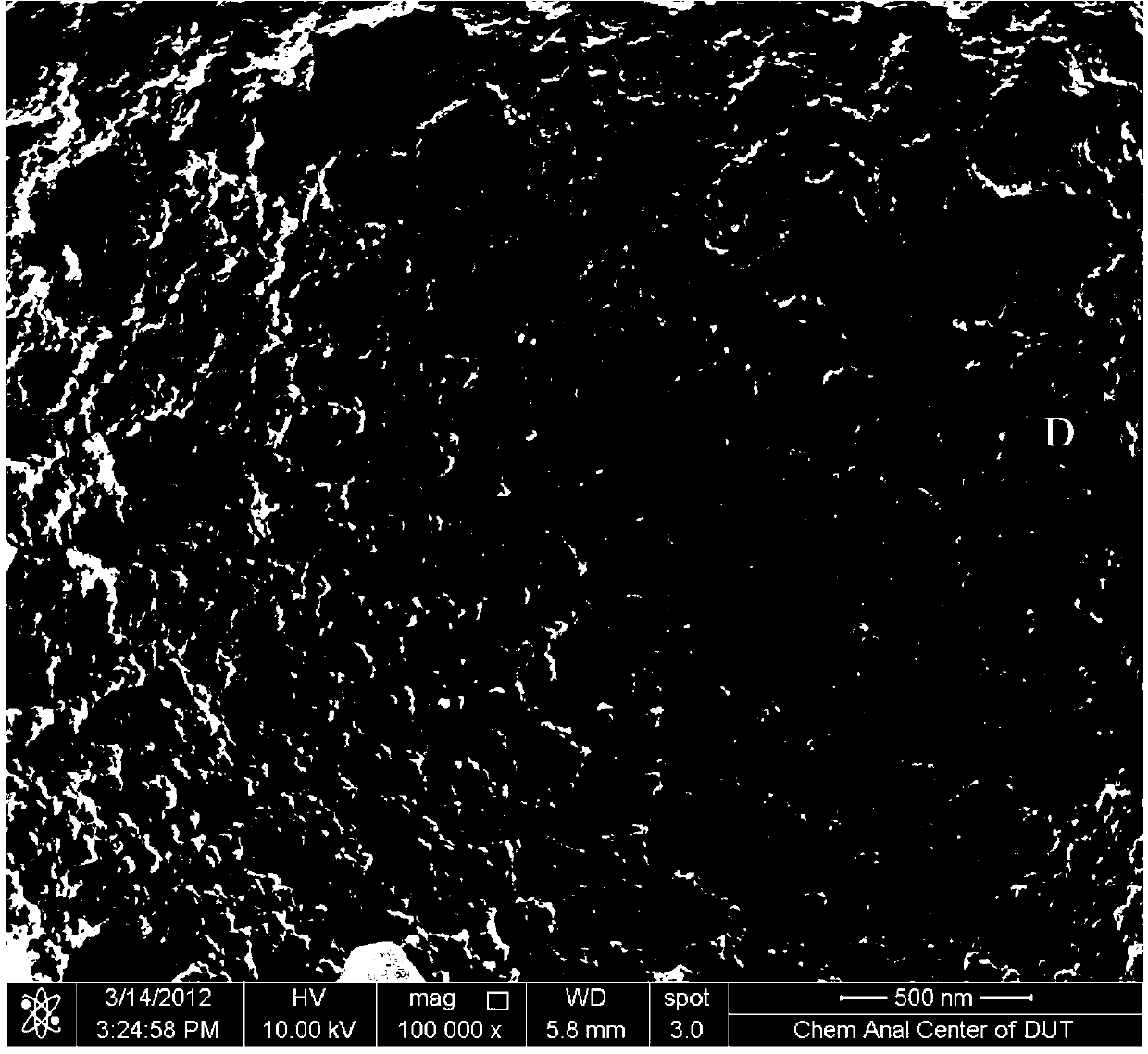

[0032] Make up N,N-dimethylformaldehyde containing bisphenol A (0.15 mmol), methacrylic acid (102 μL), trimethylolpropane trimethacrylate (0.93 mL), and azoisobutyronitrile (21.35 mg). Amide (0.87mL) solution (solution A) and 2 mg / mL graphene in N,N-dimethylformamide solution (solution B); add 0.5mL solution A to solution B, sonicate for 10 minutes, nitrogen Oxygen for 5 minutes to form a prepolymer solution.

[0033] Insert the quartz capillary into the pre-polymer solution, and when the pre-polymer solution is full of the capillary, seal both ends of the capillary with a silicone rubber pad, and place it in a 65°C water bath for 24 hours; immerse the middle of the quartz capillary in 25% hydrofluoric acid for 2 hours , to obtain a polymer fiber wi...

Embodiment 2

[0035] Take a quartz capillary with an inner diameter of 0.25mm and a length of 10cm, wash it with 0.1N sodium hydroxide and hydrochloric acid for 30 minutes, wash it with deionized water until neutral, and dry it with nitrogen.

[0036] A configuration containing bisphenol A (0.15 mmol), methacrylic acid (102 μL), trimethylolpropane trimethacrylate (0.93 mL), azoisobutyronitrile (21.35 mg) and N,N-dimethylformaldehyde Amide (0.87mL) solution (solution A) and 2 mg / mL graphene N,N-dimethylformamide solution (solution B); add 0.5mL solution A to solution B, sonicate for 10 minutes, nitrogen deoxygenation 5min to form a prepolymer solution.

[0037] Insert the quartz capillary into the pre-polymer solution, and when the pre-polymer solution is full of the capillary, seal both ends of the capillary with a silicone rubber pad, and place it in a 65°C water bath for 24 hours; immerse the middle of the quartz capillary in 25% hydrofluoric acid for 2 hours , to obtain a polymer fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com