Composite nanocapsule phase-change material and preparation method thereof

A technology of nanocapsules and phase change materials, applied in heat exchange materials, chemical instruments and methods, silicon oxide, etc., can solve problems such as difficult nanometer-sized composite nanocapsule materials, and achieve large specific surface area and high coating efficiency , the effect of reducing the damage of the capsule structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

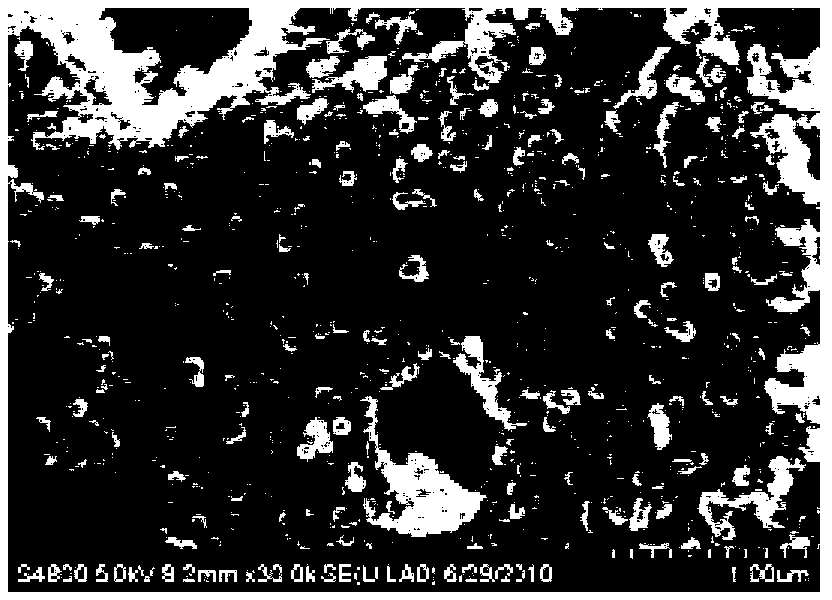

preparation example Construction

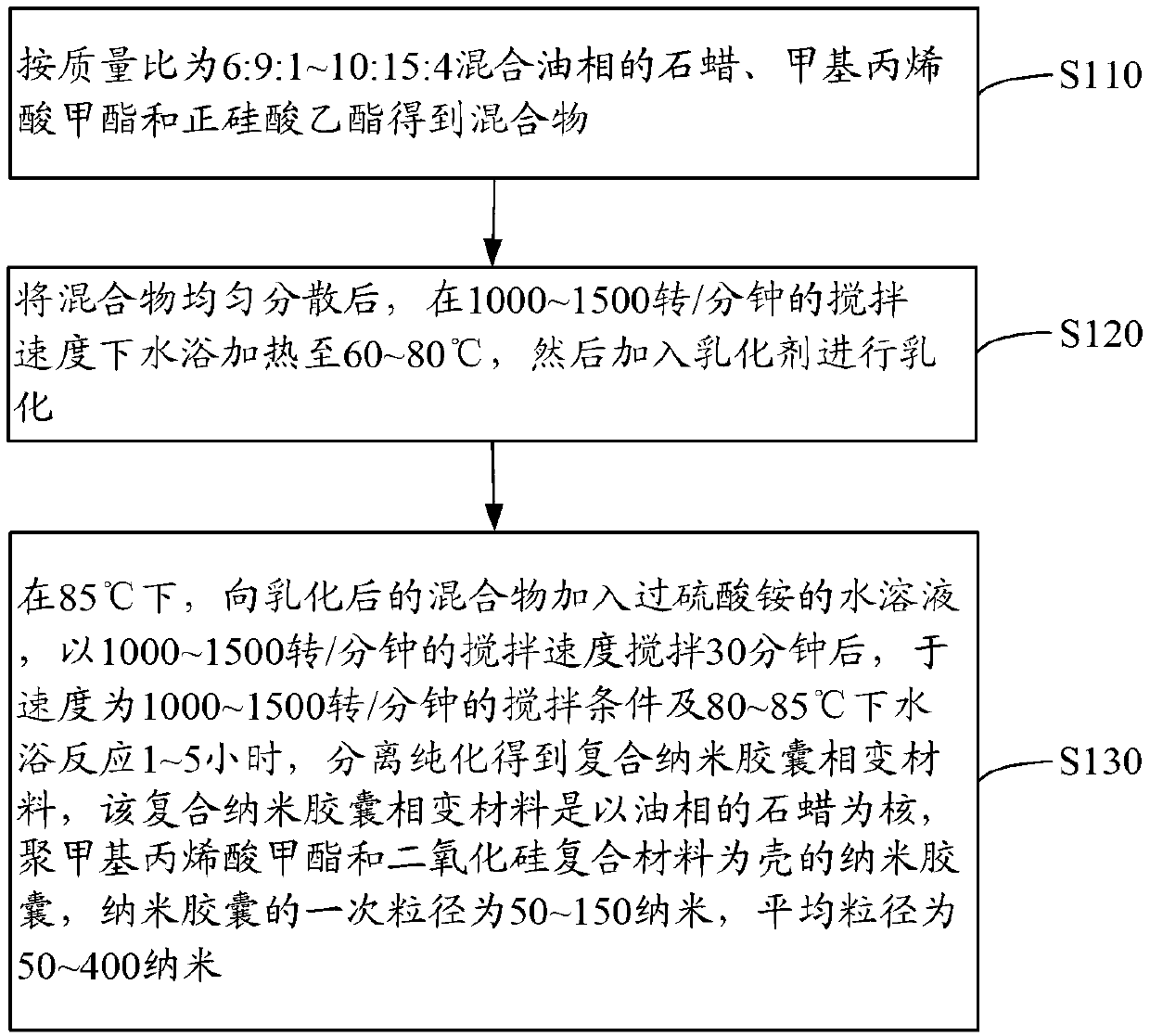

[0052] The preparation method of the above-mentioned composite nanocapsule phase change material cites the synergistic effect between the interfacial polymerization reaction and the hydrolysis reaction, which controls the overall reaction speed of the reaction system well, so that the prepared composite nanocapsule phase change material has a good Structural uniformity and stability, so as to control the primary particle diameter of the composite nanocapsule phase change material to be 50-400 nanometers, and the average particle diameter to be 50-400 nanometers.

[0053] The introduction of ammonium persulfate, which can be used as both a monomer initiator and an ester hydrolysis catalyst, enables the interfacial polymerization reaction of methyl methacrylate and the interfacial hydrolysis reaction of ethyl orthosilicate to proceed simultaneously, further improving the composite nanocapsule phase. The structural uniformity and stability of the material can be changed, so that t...

Embodiment 1

[0057] Preparation of composite nanocapsule phase change materials

[0058] (1) Mix paraffin wax, methyl methacrylate and ethyl orthosilicate in the oil phase at a mass ratio of 6:9:1 to obtain a mixture;

[0059] (2) After the above mixture was uniformly dispersed by ultrasonic waves for 2 minutes, it was added to a 500mL round bottom flask, stirred with sheet stainless steel, heated to 60°C in a water bath at a stirring speed of 1500 rpm, and 1g of dodecane Sodium phenylbenzenesulfonate was added to 42.5mL of deionized water to disperse evenly, and added to a round bottom flask for emulsification for 20 minutes, then heated to 80°C, and continued to emulsify for 10 minutes at a stirring speed of 1500 rpm to obtain Uniform milky white microemulsion, wherein the ratio of the quality of sodium dodecylbenzenesulfonate to the sum of the quality of paraffin wax, methyl methacrylate and tetraethyl orthosilicate in the oil phase is 1:13;

[0060] (3) After the emulsification is com...

Embodiment 2

[0066] Preparation of composite nanocapsule phase change materials

[0067] (1) Mix paraffin wax, methyl methacrylate and ethyl orthosilicate in the oil phase at a mass ratio of 10:15:4 to obtain a mixture;

[0068] (2) After the above mixture was uniformly dispersed by ultrasonic waves for 2 minutes, it was added to a 500mL round bottom flask, stirred with sheet stainless steel, heated to 60°C in a water bath at a stirring speed of 1500 rpm, and 1g of dodecane Sodium phenylbenzenesulfonate was added to 42.5mL of deionized water to disperse evenly, and added to a round bottom flask for emulsification for 10 minutes, then heated to 80°C, and continued to emulsify for 20 minutes at a stirring speed of 1500 rpm to obtain Uniform milky white microemulsion, wherein the ratio of the quality of sodium dodecylbenzenesulfonate to the sum of the quality of paraffin wax, methyl methacrylate and tetraethyl orthosilicate in the oil phase is 1:25;

[0069] (3) After the emulsification is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com