Instant drink powders comprising hydrolyzed whole grain

A whole grain and beverage technology, applied in food preparation, food science, application, etc., can solve the problems affecting the physical properties of instant beverage powder, large calorie intake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Example 1 - Preparation of Hydrolyzed Whole Grain Compositions

[0136] Enzyme compositions comprising Validase HT425L (alpha-amylase) optionally combined with Alcalase 2.4L (protease) were used for the hydrolysis of wheat, barley and oats.

[0137] Mixing can be performed in a double jacketed digester, although other industrial equipment can be used. The scraper mixer works continuously and scrapes the inner surface of the scraper mixer. It prevents product from burning and helps maintain an even temperature. Thus better control of enzyme activity. Steam can be injected into the double jacket to raise the temperature, while cold water is used to lower it.

[0138] In one embodiment, the enzyme composition and water are mixed together at room temperature, between 10 and 25°C. At this low temperature, the enzymes of the enzyme composition have very weak activity. The whole grain component is then added and the ingredients mixed briefly, usually less than 20 minutes,...

Embodiment 2

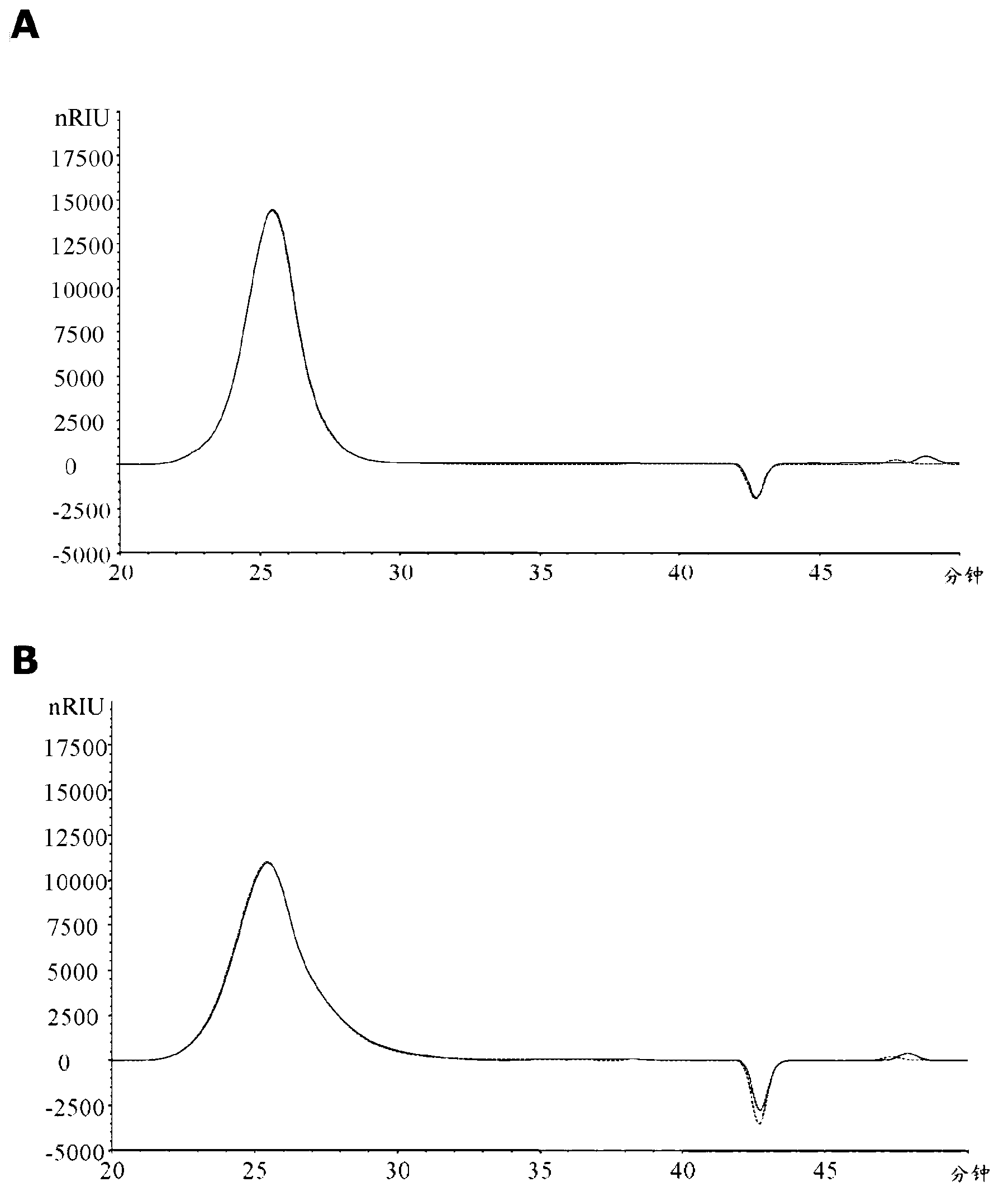

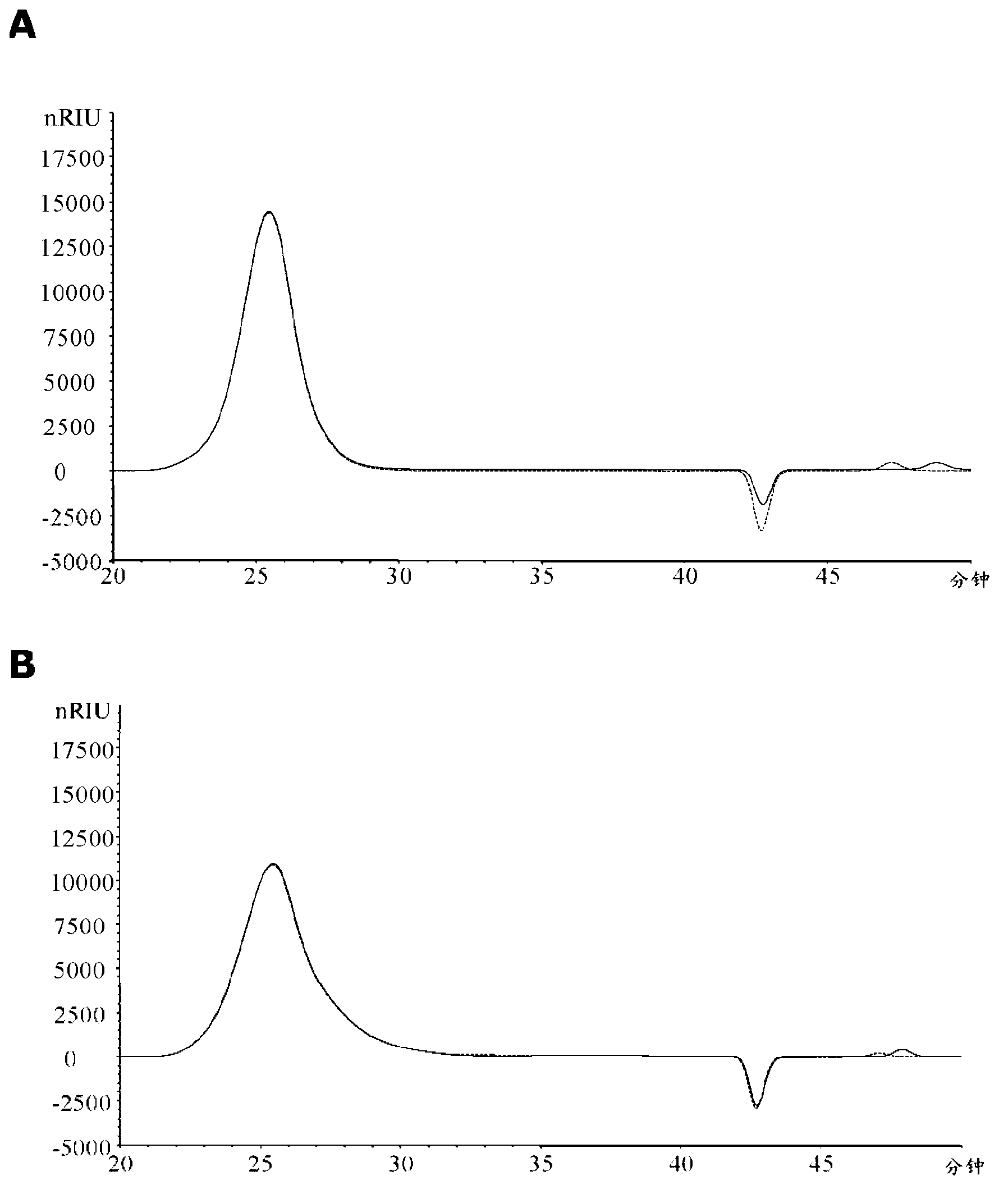

[0145] Example 2 - Sugar Profile of Hydrolyzed Whole Grain Compositions

[0146] Hydrolyzed whole grain compositions comprising wheat, barley and oats were prepared according to the method in Example 1.

[0147] Carbohydrate HPAE:

[0148] The hydrolyzed whole grain composition was analyzed by HPAE to illustrate the sugar distribution of the hydrolyzed whole grain composition.

[0149] Carbohydrates are extracted with water and separated by ion chromatography on an anion exchange column. Eluted compounds were detected electrochemically with a pulsed amperometric detector and quantified by peak area comparison with an external standard.

[0150] Total Dietary Fiber:

[0151] Duplicate samples (defatted, if desired) were digested for 16 hours with 3 enzymes (pancreatic alpha-amylase, protease and amyloglucosidase) in a manner mimicking the human digestive system to remove starch and protein. Ethanol was added to precipitate high molecular weight soluble dietary fiber. The r...

Embodiment 3

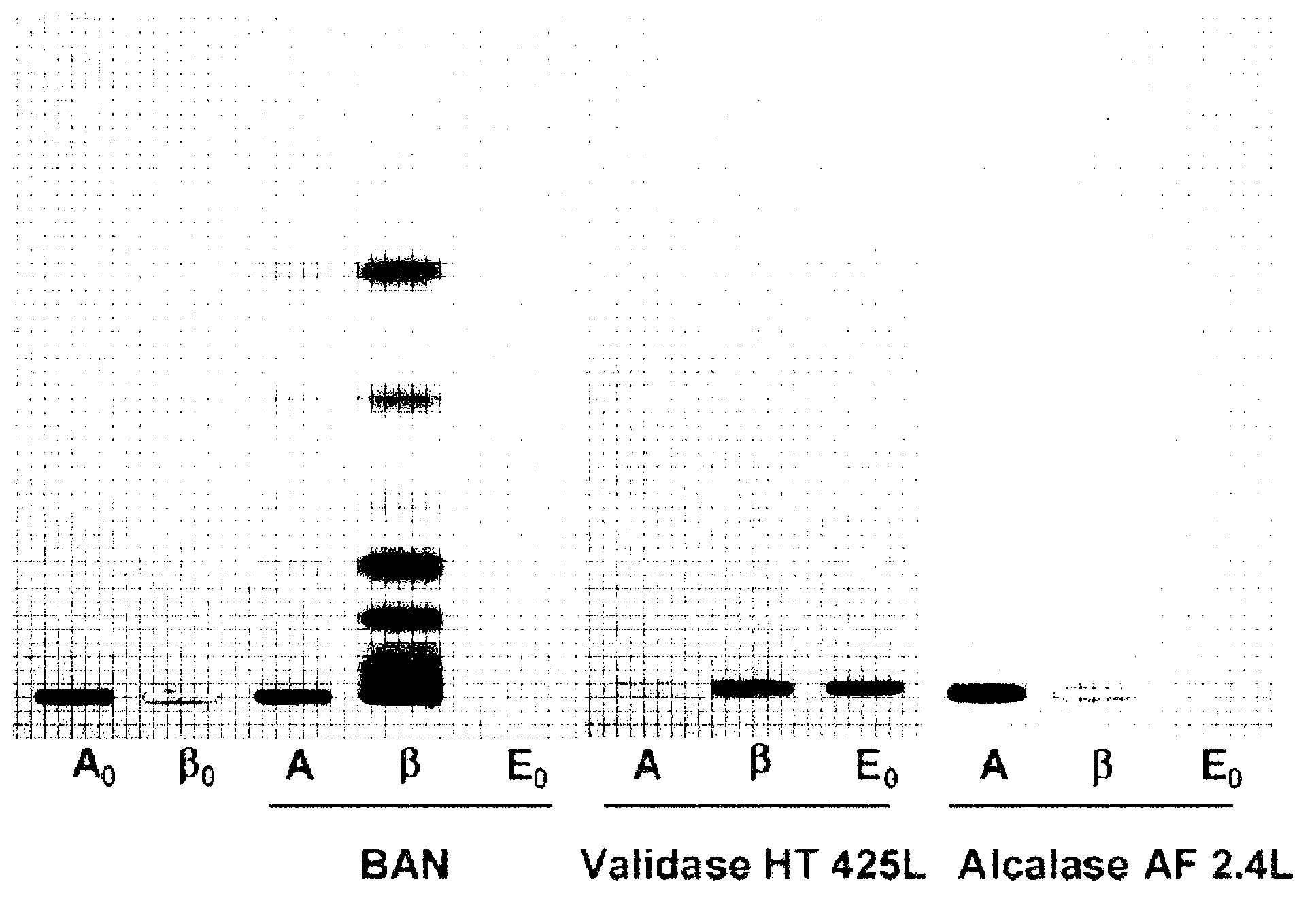

[0165] Example 3 - Hydrolytic activity on dietary fiber

[0166] Extraction of Two Components Arabinoxylan and β-Glucan Fibers from Whole Grain Dietary Fiber Using Thin Layer Chromatography Analysis of Enzymes Validase HT425L (Valley Research), Alcalase2.4L (Novozymes) and BAN (Novozymes) activity of the substance.

[0167] The results of thin-layer chromatography analysis showed that the amylase Validase HT and the protease Alcalase showed no hydrolytic activity on β-glucan or arabinoxylan, while the commercially available α-amylase preparation BAN, resulted in β-glucan and arabinoxylan hydrolysis, see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com