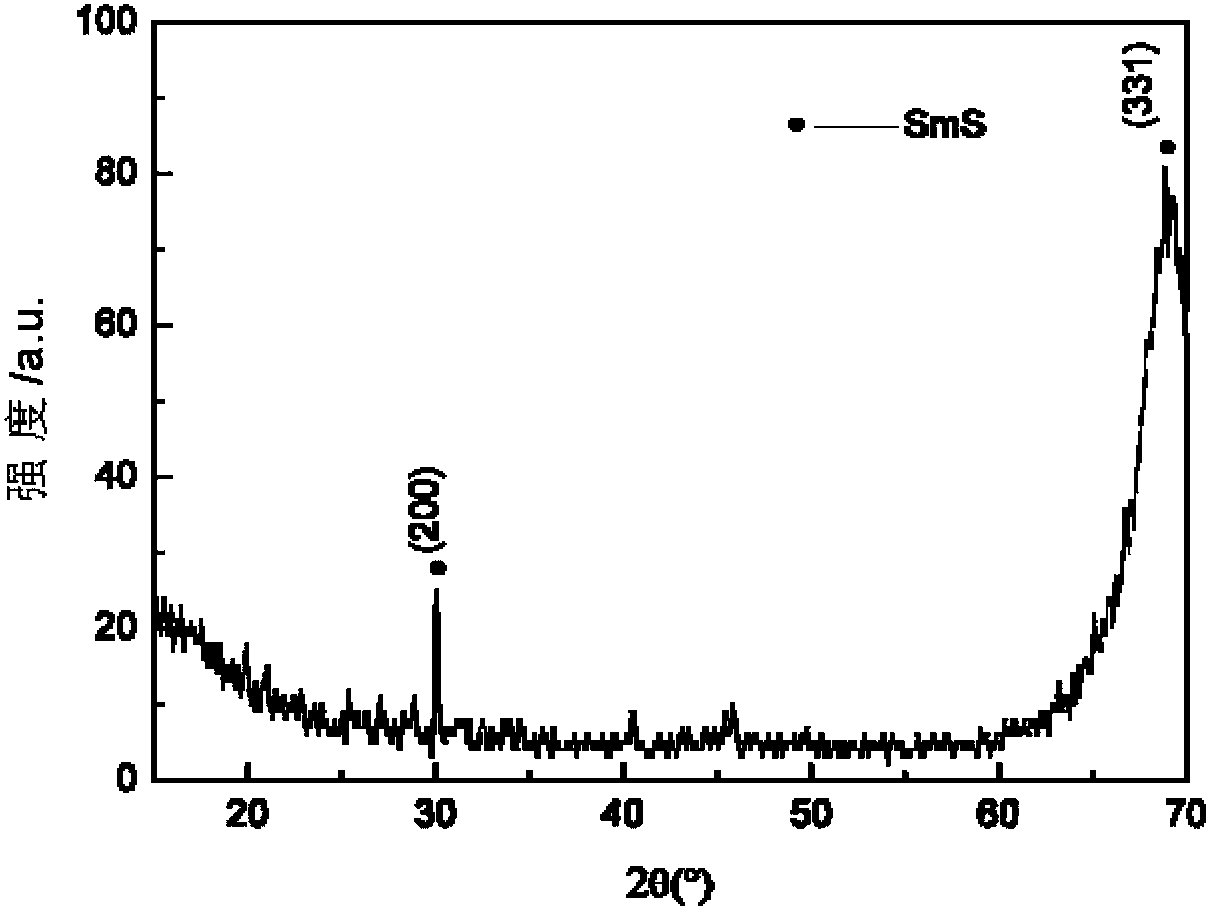

Solvothermal method for preparing SmS nanoarray

A technology of nano-array and solvothermal method, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, difficult process control, expensive equipment, etc., to avoid curling, low reaction temperature, crystal grain Growth Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Add analytically pure SmCl 3 ·6H 2 O was dissolved in a certain amount of absolute ethanol to prepare Sm 3+ A transparent solution with a concentration of 0.05 mol / L is marked as A. will analyze pure CS 2 Dissolved in a certain amount of absolute ethanol to prepare S 2- A transparent solution with a concentration of 0.1mol / L is marked as B;

[0024] Step 2: Mix solutions A and B according to a volume ratio of 2:1, and after stirring evenly, adjust the pH of the system to 4.5 with a 5% ammonia solution by mass percentage to obtain a precursor solution C;

[0025] Step 3: Place the cleaned Si(100) substrate in an ultraviolet irradiation instrument, irradiate it at a wavelength of 185nm for 10 minutes, and then soak it in octadecyltrichlorosilane-toluene solution (volume ratio 1:100) After 20 minutes, take out the substrate and wash it with acetone and absolute ethanol for 3 times, place it in an electric vacuum oven and dry it at 100°C for 10 minutes, then pu...

Embodiment 2

[0030] Step 1: Add analytically pure SmCl 3 ·6H 2 O was dissolved in a certain amount of absolute ethanol to prepare Sm 3+ A transparent solution with a concentration of 0.10 mol / L is marked as A. will analyze pure CS 2 Dissolved in a certain amount of absolute ethanol, prepared as S 2- A transparent solution with a concentration of 0.05mol / L is marked as B;

[0031] Step 2: Mix solutions A and B according to the volume ratio of 1:3, and after stirring evenly, adjust the pH of the system to 6.0 with 5% ammonia solution by mass percentage to prepare precursor solution C;

[0032] Step 3: Place the cleaned Si(100) substrate in a UV irradiation instrument, irradiate it at a wavelength of 185nm for 15 minutes, and then soak it in an octadecyltrichlorosilane-toluene solution (volume ratio 1:100) After 30 minutes, take out the substrate and wash it with acetone and absolute ethanol for 4 times, place it in an electric vacuum oven and dry it at 120°C for 8 minutes, and then put ...

Embodiment 3

[0037] Step 1: Add analytically pure SmCl 3 ·6H 2 O was dissolved in a certain amount of absolute ethanol to prepare Sm 3+ A transparent solution with a concentration of 0.15 mol / L is marked as A. will analyze pure CS 2 Dissolved in a certain amount of absolute ethanol, prepared as S 2- A transparent solution with a concentration of 0.15mol / L is marked as B;

[0038] Step 2: Mix solutions A and B according to a volume ratio of 1:1, and after stirring evenly, adjust the pH of the system to 5.5 with 5% ammonia solution by mass percentage to prepare precursor solution C;

[0039] Step 3: Place the cleaned Si(100) substrate in a UV irradiation instrument, irradiate it with light at a wavelength of 185nm for 20 minutes, and then soak it in octadecyltrichlorosilane-toluene solution (volume ratio 1:100) After 25 minutes, take out the substrate and wash it with acetone and absolute ethanol for 5 times, place it in an electric vacuum oven and dry it at 140°C for 6 minutes, then pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com