CIGS (Copper Indium Gallium Selenium) solar cell back-electrode Mo film and preparation technology thereof

A technology of solar cells and copper indium gallium selenide, applied in the field of solar cells, can solve problems such as lattice mismatch, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

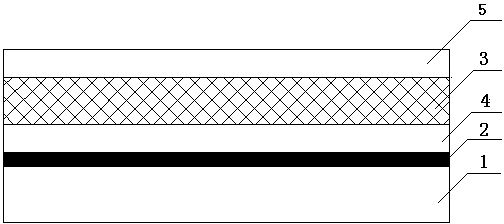

[0025] Such as figure 1 As shown, a Mo film on the back electrode of a copper indium gallium selenide solar cell includes a glass substrate 1, a Mo oxide layer 2, an inner Mo film 3 and an outer Mo film 4, and the Mo oxide layer 2 is attached to the glass substrate 1 Above, the inner Mo film 3 is attached to the Mo oxide layer 2, and the outer Mo film 4 is attached to the inner Mo film 3, wherein the composition of the Mo oxide layer 1 is MoO 2 .

[0026] The preparation process of the Mo thin film of the back electrode of the copper indium gallium selenide solar cell is as follows:

[0027] Soak the sliced glass in alkaline solution for one night, after deionized washing, then ultrasonically clean it in acidic solution for 30 minutes, then after deionized washing, pass through acetone, absolute ethanol and deionized water successively, each Ultrasonic cleaning for 10 minutes, and finally dried with nitrogen gas for later use. Put the clean glass substrate into the ma...

Embodiment 2

[0032] A copper indium gallium selenide solar cell back electrode Mo thin film, comprising a glass substrate 1, a Mo oxide layer 2, an inner Mo thin film 3 and an outer Mo thin film 4, the Mo oxide layer 2 is bonded on the glass substrate 1, and the inner Layer Mo film 3 is pasted on the Mo oxide layer 2, and the outer Mo film 4 is pasted on the inner Mo film 3, wherein the composition of Mo oxide layer 1 is MoO 3 .

[0033] The preparation process of the Mo thin film of the back electrode of the copper indium gallium selenide solar cell is as follows:

[0034] Soak the sliced glass in alkaline solution for one night, after deionized washing, then ultrasonically clean it in acidic solution for 30 minutes, then after deionized washing, pass through acetone, absolute ethanol and deionized water successively, each Ultrasonic cleaning for 10 minutes, and finally dried with nitrogen gas for later use. Put the clean glass substrate into the magnetron sputtering chamber, and the ...

Embodiment 3

[0039] A copper indium gallium selenide solar cell back electrode Mo thin film, comprising a glass substrate 1, a Mo oxide layer 2, an inner Mo thin film 3 and an outer Mo thin film 4, the Mo oxide layer 2 is bonded on the glass substrate 1, and the inner Layer Mo thin film 3 is pasted on the Mo oxide layer 2, and the outer Mo thin film 4 is pasted on the inner Mo thin film 3, wherein the composition of the Mo oxide layer 1 is Mo 4 o 11 .

[0040] The preparation process of the Mo thin film of the back electrode of the copper indium gallium selenide solar cell is as follows:

[0041] Soak the sliced glass in alkaline solution for one night, after deionized washing, then ultrasonically clean it in acidic solution for 30 minutes, then after deionized washing, pass through acetone, absolute ethanol and deionized water successively, each Ultrasonic cleaning for 10 minutes, and finally dried with nitrogen gas for later use. Put the clean glass substrate into the magnetron sput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com