Hydrogel with micro-flow passage, as well as preparation method and application thereof

A technology of microfluidic channels and hydrogels, which is applied in biochemical equipment and methods, microbial measurement/inspection, medical science, etc., can solve problems such as high cost, cell damage, and complicated preparation methods, and achieve good mechanical strength, High controllability, support adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

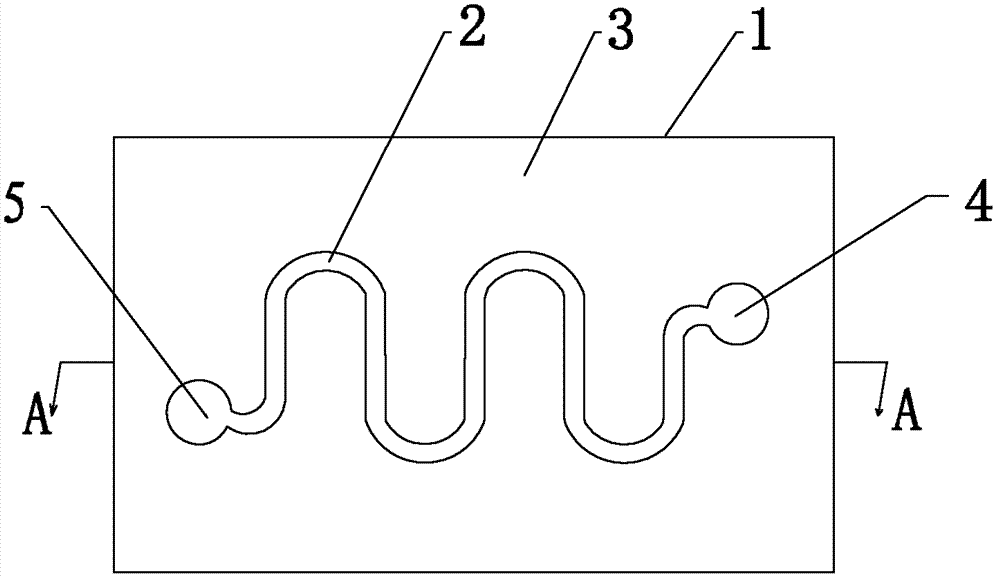

[0054] Such as Figure 1-2 and Figure 5-7 As shown, the hydrogel 1 with a microfluidic channel according to the present invention includes a hydrogel base layer 7 and a hydrogel structure layer 6 bonded thereto, and the hydrogel structure layer 6 and the hydrogel base A microfluidic groove is provided on the bonded surface of the bottom layer 6, and the microfluidic groove and the hydrogel base layer 7 jointly form a microfluidic channel 2 for fluid circulation, and the hydrogel structural layer 6 or water On the other surface of the gel base layer 7 away from the bonding, perforations are respectively provided at positions corresponding to the two ports of the microfluidic channel 2 to form the channel inlet 4 and the channel outlet 5 of the microfluidic channel, so The hydrogel base layer 7 and the hydrogel structure layer 6 are all made of hydrogel containing sodium alginate and fibrous protein, and the hydrogel also contains alkaline earth metal salts, and the hydrogel b...

Embodiment approach 2

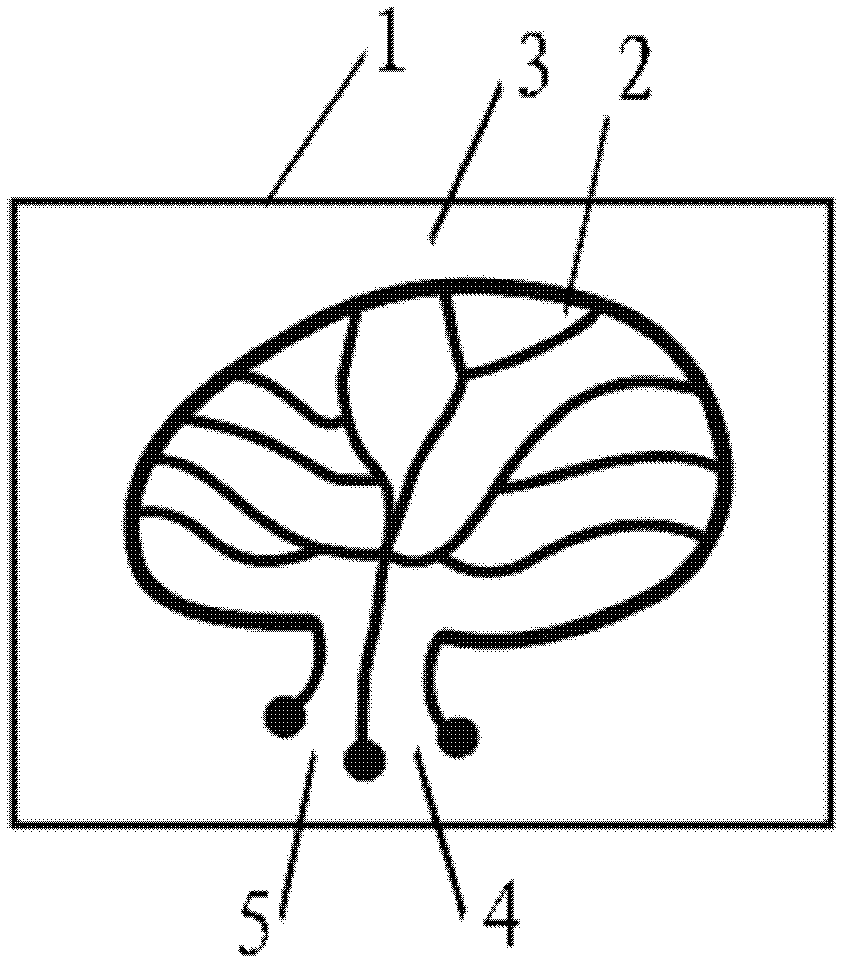

[0056] Such as Figure 3-4 As shown, the hydrogel with microfluidic channels described in the present invention has the same structure as the hydrogel with microfluidic channels in Embodiment 1, except that the shape of the microfluidic channels 2 is different.

[0057] Test materials used in the following examples: human umbilical vein endothelial cells (HUVEC cells) were purchased from the cell bank of Peking Union Medical College Hospital; MDCK kidney epithelial cells were purchased from the cell bank of Peking Union Medical College Hospital.

Embodiment 1

[0059] The first step: according to the shape of the required microfluidic groove, the specific size of the first mold with a protrusion compatible with the microfluidic groove is designed by CAD software, and the specific size of the second mold, said The width of the microfluidic groove is 200 μm, and the height is 200 μm, and the first and second molds of silicon rubber are made of silicon rubber materials by methods including photolithography and overmolding (see Microfluidic Chip Laboratory, Science Press, 2006); then on ice, mixed with sodium alginate (3% w / w) and type I collagen (3 mg / mL), and 10% DMEM 10X, 10% PBS 10X, 5 μL 1M NaOH and 100 μL deionized A hydrogel prepolymer in water is poured over the silicone rubber first mold.

[0060] The second step: increasing the temperature (to 37°C) and adding calcium chloride aqueous solution (60mM) to solidify type I collagen and sodium alginate hydrogel successively to form a hydrogel structure layer with microfluidic groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com