Methanol rejective membrane for direct methanol fuel cell as well as preparation method and application thereof

A technology of methanol fuel cell and alcohol barrier film, which is applied to fuel cell parts, battery pack parts, circuits, etc. It can solve the problems of expensive catalyst, high oxidation overpotential, slow methanol oxidation rate, etc., and achieve high power efficiency. Density and fuel utilization, reduced methanol penetration, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Preparation and Application of Monolayer GO Modified Alcohol-resisting Film

[0070] The preparation steps of the monolayer GO modified alcohol barrier film are as follows:

[0071] 1. Pretreatment of Nafion membrane

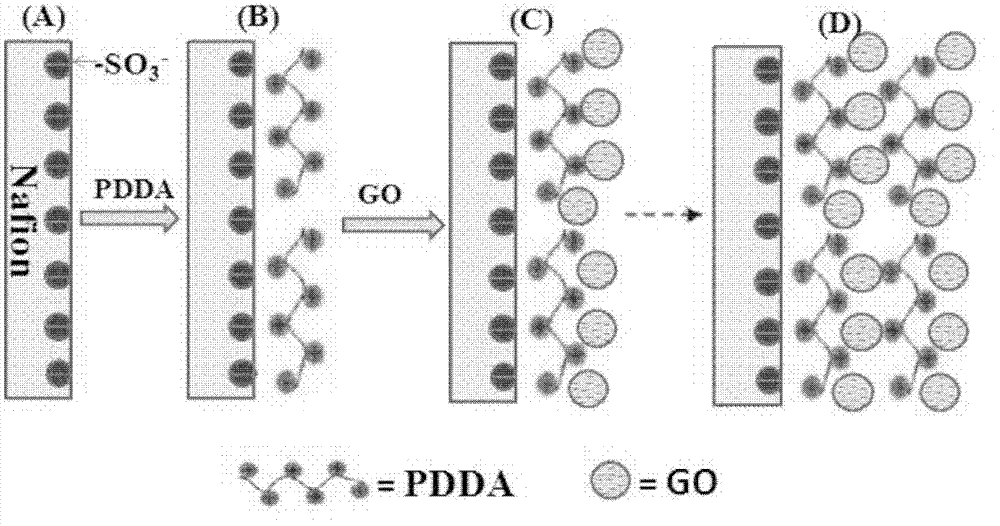

[0072] Cut two pieces of 3cm×3cm DuPont’s Nafion212 film, put in 5wt.%H 2 o 2 Boil in aqueous solution for about 1 hour until the light yellow film becomes colorless and transparent; rinse 8 times with ultrapure water; then rinse with 0.5M H 2 SO 4 Boil for about 1 hour to protonize the membrane; then wash it with ultrapure water 8 times to get the following figure 1 The membrane (A) shown is stored in ultrapure water for future use.

[0073] 2. Preparation of graphene oxide

[0074] Weigh 11g K 2 S 2 o 8 and 18g P 2 o 5 Placed in a three-necked flask, add 80mL of concentrated H 2 SO 4 After the oil bath was heated to 80°C, 10g of dried natural flake graphite powder (particle size less than 45 μm) was added, and the heating was stopped when t...

Embodiment 2

[0093] Preparation and Application of Example 2 Double-layer GO Modified Alcohol-resisting Membrane

[0094] The preparation steps of the bilayer GO-modified alcohol barrier film are as follows:

[0095] 1. Pretreatment of Nafion membrane

[0096] Cut two pieces of 3cm×3cm Nafion212 film, put in 5wt.%H 2 o 2 Boil in aqueous solution for about 1 hour until the light yellow film becomes colorless and transparent; rinse 5 times with ultrapure water; then rinse with 0.5M H 2 SO 4 After boiling for about 1 hour, the membrane is protonated; then washed 5 times with ultrapure water to obtain the following figure 1 The membrane (A) shown is stored in ultrapure water for future use.

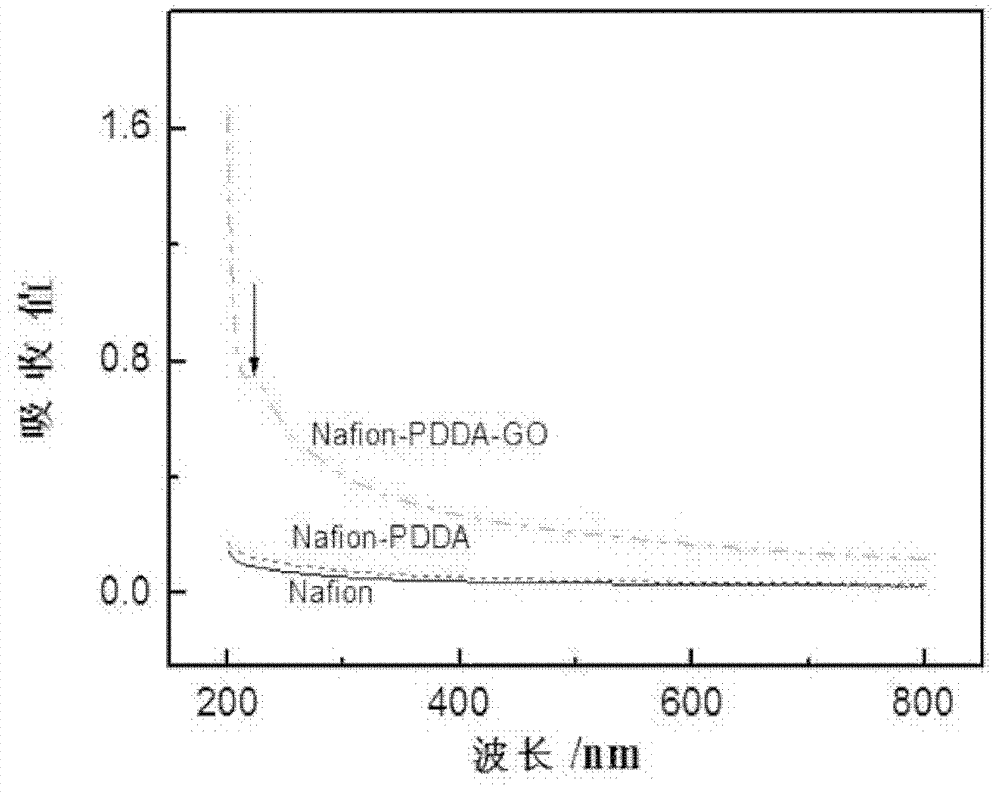

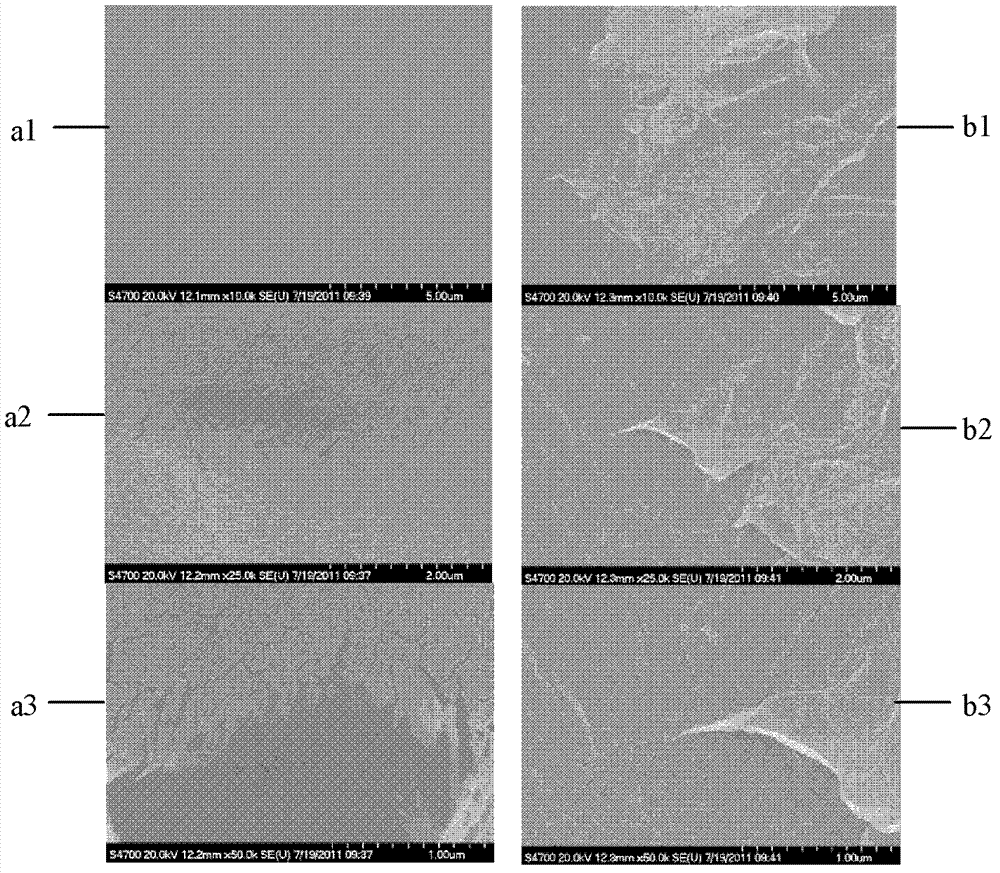

[0097] 2. Preparation of alcohol barrier film

[0098] The above film (A) was soaked in 20mM PDDA solution for 10 minutes, taken out and rinsed with ultrapure water, and dried naturally to obtain the film (B), soaked in the graphene oxide aqueous dispersion described in Example 1 for 10 minutes, Ta...

Embodiment 3

[0104] Example 3 Preparation and application of monolayer GO modified alcohol barrier film

[0105] The preparation steps of the monolayer GO modified alcohol barrier film are as follows:

[0106] 1. Pretreatment of Nafion membrane

[0107] Cut a piece of 3cm×3cm DuPont’s Nafion212 film, put it in 3wt.%H 2 o 2 Boil in aqueous solution for about 2 hours until the light yellow film becomes colorless and transparent; rinse with ultrapure water for 6 times; then rinse with 1M H 2 SO 4 Cook for about 2 hours to protonize the membrane; then wash it with ultrapure water for 6 times to obtain the following figure 1 The membrane (A) shown is stored in ultrapure water for future use.

[0108] 2. Preparation of graphene oxide

[0109] Weigh 5g K 2 S 2 o 8 and 10g P 2 o 5 Placed in a three-neck flask, add 50 mL of concentrated H 2 SO 4 After the oil bath was heated to 50°C, 5g of dried natural flake graphite powder (particle size less than 45 μm) was added, and the heating wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com