Method for synthesizing modified sodium alginate flocculating agent and application of flocculating agent

A technology of sodium alginate and flocculant, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problems of complicated operation and secondary pollution, and achieve good selectivity and sedimentation speed. Fast, large adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

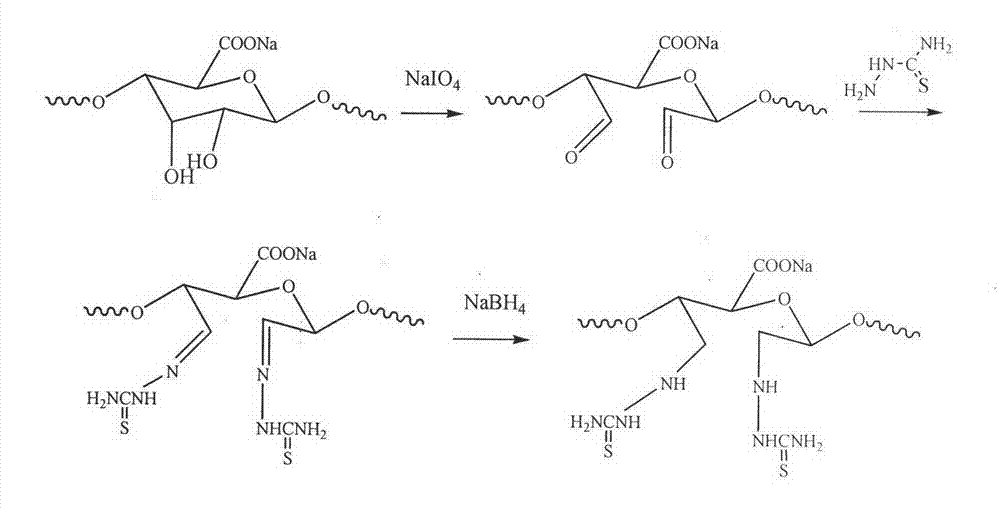

[0021] Prepare 8g of sodium alginate (SA) with distilled water into a uniform solution with a concentration of 2.5%, add 10ml of n-propanol and 80ml of sodium periodate solution (0.3mol / L), react in the dark at 4°C for 24h, add 1ml of ethyl alcohol The diol terminated the oxidation reaction for 15 min. Use absolute ethanol to precipitate the precipitate, filter it with suction and dissolve it with deionized water, then separate it with ethanol again, filter it with suction, repeat this step 3 times, put the white product into a watch glass, and dry it in vacuum at 40°C for 24 hours to obtain the oxidized Sodium Alginate OSA.

Embodiment 2

[0023] In a three-necked flask, dissolve 2.0 g of the oxidized sodium alginate in Example 1 in 20 mL of phosphate buffer (pH=7.0) to form a uniform solution, then add 50 mL of an aqueous solution containing 0.5 g of thiosemicarbazide (TSC), 40 Stir the reaction at ℃ for 4h, add 1.0g NaBH after cooling to 20℃ 4 , complete reaction 24h. The reaction product was precipitated with ethanol, filtered with suction, soaked with ethanol, washed, and filtered with suction. This step was repeated four times, and vacuum-dried at 30°C for 24 hours to obtain modified sodium alginate flocculant (SA-TSC1).

Embodiment 3

[0025] 50 mL of an aqueous solution containing 1.0 g of thiosemicarbazide was added to the reactor, and the other steps were the same as in Example 2 to prepare the modified sodium alginate flocculant SA-TSC2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com