Method for separating titanium resource in titanium slag through super gravity

A super-gravity, titanium slag technology, applied in centrifuges, centrifuges with rotating drums, recycling technology, etc., can solve the effect of magnetic separation is not very effective, perovskite and titanium pyroxene magnetic susceptibility The problem is not much different, so as to achieve the effect of solving the environmental load and realizing the comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

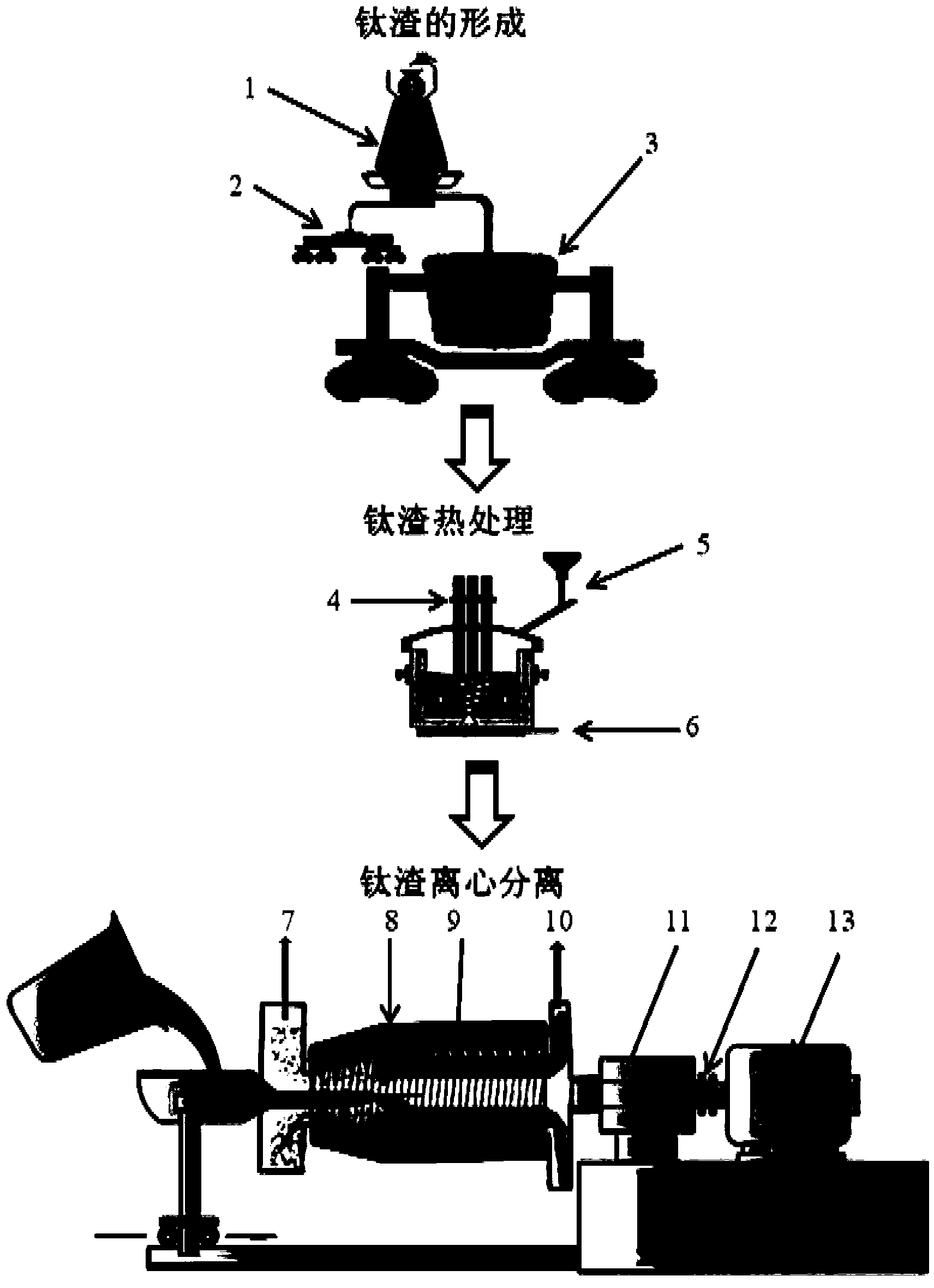

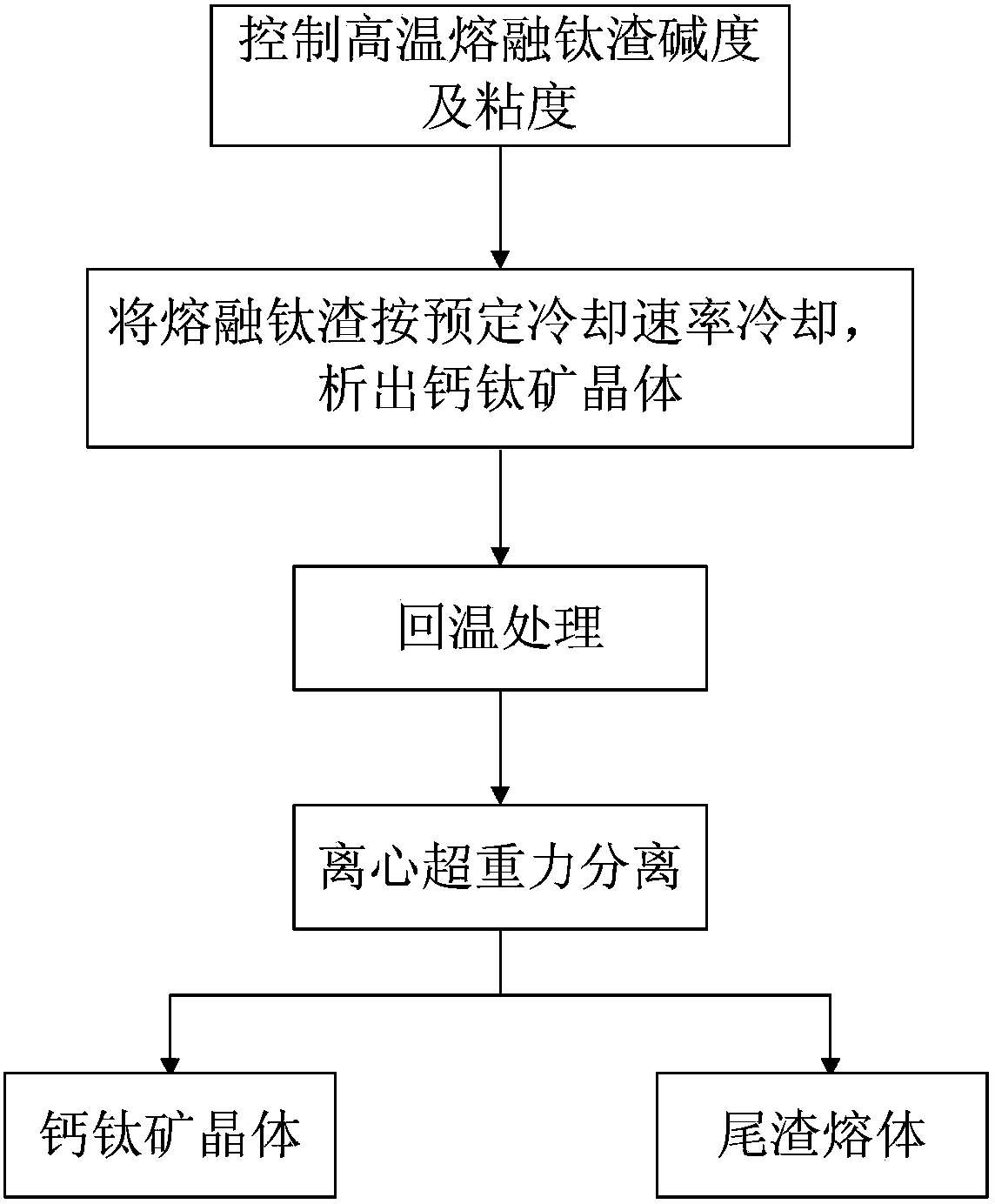

Method used

Image

Examples

Embodiment 1

[0043] Prepare 10kg of simulated Panzhihua Iron and Steel blast furnace slag with a basicity of 1.3: (CaO-TiO 2 -SiO 2 -Al 2 o 3 -MgO five-element slag), heated to 1500°C for 30 minutes to ensure that the ingredients are evenly mixed, then cooled to 1320°C, and then at a cooling rate of 0.5°C / min in the temperature range of 1250-1320°C to promote the titanium element in the titanium slag to calcium The titanite phase is enriched and eventually precipitates and grows in the form of perovskite crystals. After the slag heat treatment is completed, adjust the slag temperature to 1300°C and immediately start the centrifuge with a built-in ceramic feeding inner spiral lining, adjust the speed of the centrifuge so that the gravity coefficient is 450g, and after centrifuging at a constant temperature for 15 minutes, turn off the centrifuge. The sample from the solid outlet at the small end of the drum was ground into powder for fluorescence analysis. The composition of the titaniu...

Embodiment 2

[0045] Prepare 10kg basicity as the simulation Panzhihua Iron and Steel blast furnace slag (CaO-TiO 2 -SiO 2 -Al 2 o 3 -MgO five-element slag), heated to 1500°C for 30 minutes, then cooled to 1320°C, and then at a cooling rate of 0.5°C / min in the temperature range of 1250-1320°C to promote the enrichment of titanium in the titanium slag to the perovskite phase , eventually precipitated and grew up in the form of perovskite crystals. After the heat treatment of the slag is completed, adjust the temperature of the slag to 1300°C and immediately start the centrifuge with a built-in ceramic feeding inner spiral lining, adjust the speed of the centrifuge so that the gravity coefficient is 750g, and control the cooling rate at about 1-5°C / min. After the temperature dropped to 1150°C, the centrifuge was turned off and cooled naturally. The sample from the solid outlet at the small end of the drum was ground into powder for fluorescence analysis. The test results show that the re...

Embodiment 3

[0047] Prepare 10kg basicity as the simulation Panzhihua Iron and Steel blast furnace slag (CaO-TiO 2 -SiO 2 -Al 2 o 3 -MgO five-element slag), heated to 1500°C for 30 minutes, then cooled to 1320°C, and then at a cooling rate of 0.5°C / min in the temperature range of 1290-1320°C to promote the enrichment of titanium in the titanium slag to the perovskite phase , eventually precipitated and grew up in the form of perovskite crystals. After the heat treatment of the slag is completed, adjust the temperature of the slag to 1300°C and immediately start the centrifuge with a built-in porous ceramic filter, adjust the speed of the centrifuge so that the gravity coefficient is 750g, and control the temperature drop rate in the centrifuge to be less than 5°C / min. After reaching 1150°C, turn off the centrifuge and let it cool down naturally. The white sample retained on the filter cartridge and the black sample leaked to the outside of the filter were ground into powder for fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com