Preparation method and application of interpenetrating structure polyaniline/carbon nanotube composite nanofiber material

A carbon nanotube composite and composite nanofiber technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as color purity decline, and achieve the effects of improving stability, increasing luminous space, and expanding contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

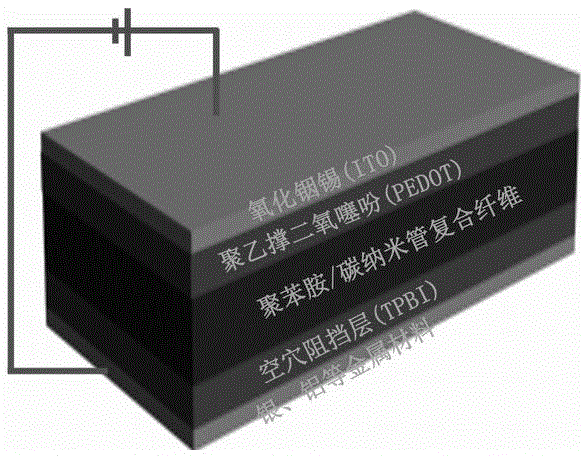

[0033] A preparation method of interpenetrating structure polyaniline / carbon nanotube composite nanofiber material, the method comprises: synthesizing polyaniline, adopting Suzuki coupling reaction, using N,N-bis(4-bromophenyl)-4- Synthesis of poly[2,7-(9,9-dioctylfluorene)-alternate-N-phenyl-N-(4-phenoxyphenyl)aniline] from (4-phenoxy)aniline monomer; Preparation Soluble carbon nanotubes; the obtained polyaniline and carbon nanotubes are dissolved in a solvent, and the interpenetrating structure polyaniline / carbon nanotube composite nanofiber material is prepared by high-voltage electrospinning technology, and the electroporation of the interpenetrating structure composite nanofiber material is prepared. luminescent device.

Embodiment 2

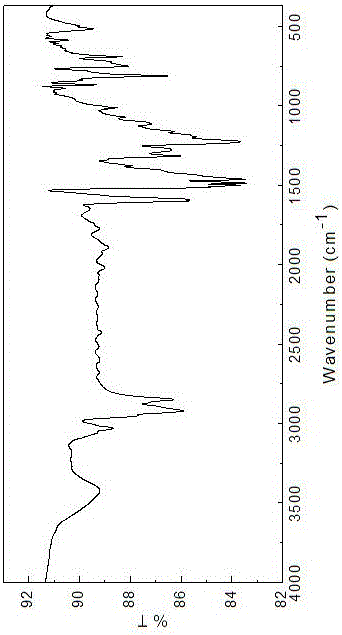

[0035] According to the preparation method of the interpenetrating structure polyaniline / carbon nanotube composite nanofiber material described in Example 1, the reaction formula of the synthetic polyaniline is shown in the following formula:

[0036] ,

[0037] The obtained N,N-bis(4-bromophenyl)-4-(4-phenoxy)aniline (Mon) monomer was purified and combined with 9,9-dioctylfluorene-2,7-diboronic acid cis ( 1,3-propylene glycol) ester is polymerized to obtain poly[2,7-(9,9-dioctylfluorene)-alternate-N-phenyl-N-(4-phenoxyphenyl)aniline];

[0038] The specific steps are as follows: using purified toluene as a solvent, wherein 10-25 mL of toluene is added to 1 mmol of aniline monomer, and 9,9-dioctylfluorene-2,7-diboronic acid cis (1,3-propanediol) ester and monomer are used. Mon is added according to the molar ratio of 1:1.0~1:1.1, and the addition ratio is 1:25~1:30 palladium catalyst Pd(PPh 3 ) 4 , the described palladium catalyst Pd (PPh 3 ) 4The ratio of 9,9-dioctylflu...

Embodiment 3

[0040] According to the preparation method of the interpenetrating structure polyaniline / carbon nanotube composite nanofiber material described in embodiment 1 or 2, the obtained polyaniline and carbon nanotubes are dissolved in a solvent, and soluble carbon nanotubes are added. , the content is 0.5~10.0% (wt.%), under the condition of 10~30 ℃, using high-voltage electrospinning technology, adjust the spinning voltage to 10~30kV, and the distance between the transmitter electrode and the receiver electrode is 5~30cm The polyaniline / carbon nanotube composite nanofiber material can be obtained on the receiving electrode by controlling the flow rate of the liquid by using a micro-injection pump. The average diameter of the nanofiber material is 100-700 nm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Dimension length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com