Polymer nano carrier preparation as well as preparation method and application thereof

A nanocarrier and polymer technology, applied in the field of nanomedicine, can solve the problems of low antigen loading rate, weak immunogenicity, limiting the wide application of nanovaccine carriers, etc., and achieve the effect of simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

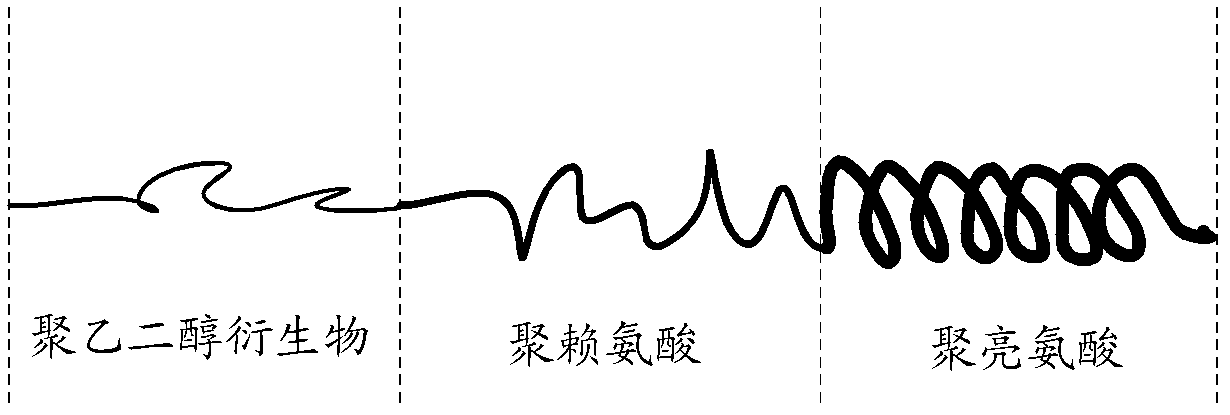

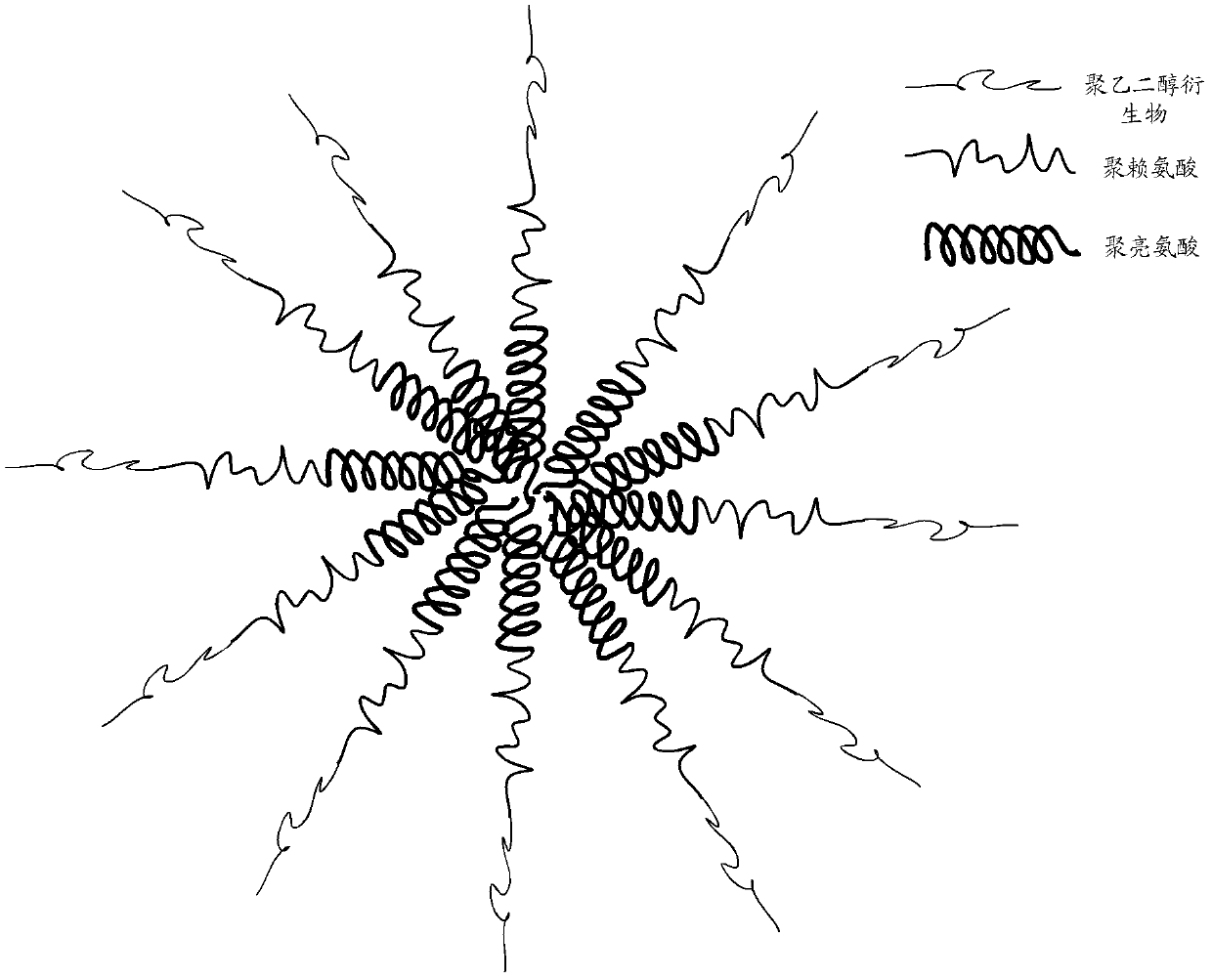

[0055] This embodiment also provides a method for preparing an amphiphilic triblock copolymer, comprising the following steps:

[0056] Step S110: Using polyethylene glycol derivatives as initiators, synthesizing linear triblock copolymers comprising polyethylene glycol derivatives, side chain-protected polylysine and polyleucine by NCA ring-opening polymerization , wherein one end of the side chain-protected polylysine is connected to polyethylene glycol derivatives through an amide bond, and the other end is connected to polyleucine through a peptide bond, and the molecular weight of the polyethylene glycol derivatives is in the range of 500-10000 , the degree of polymerization of polylysine with side chain protection is 10-200, and the degree of polymerization of polyleucine is 10-200.

[0057] The details are as follows: dissolve polyethylene glycol derivatives with a molecular weight range of 500-10000 in an organic solvent at a concentration range of 1-100 mg / mL, heat to...

example 1

[0121] Example 1, the preparation of polyethylene glycol monomethyl ether-polylysine-polyleucine triblock copolymer

[0122] The polymerization tube was evacuated and then filled with nitrogen protection, and 1 g of CH with a molecular weight of 500 3 O-PEG-NH 2 Dissolve it with 20mL DMF and add it into the polymerization tube, press LysZ-NCA monomer and CH 3 O-PEG-NH 2 The molar ratio of the LysZ-NCA monomer was added in a ratio of 10:1, and the constant temperature reaction was carried out under nitrogen protection for 24 hours, and then the Leu-NCA monomer and CH 3 O-PEG-NH 2 Add the Leu-NCA monomer with a molar ratio of 10:1, and continue to react at a constant temperature for 24 hours under the protection of nitrogen. After the reaction, add ether 50 times the volume of the reaction system to precipitate, filter, and dry to obtain PEG-PLysZ-PLeu three-block segment copolymers.

[0123] Dissolve the PEG-PLysZ-PLeu polymer obtained above in trifluoroacetic acid at 0°C,...

example 2

[0124] Example 2, the preparation of carboxypolyethylene glycol-polylysine-polyleucine triblock copolymer

[0125] After the polymerization tube was evacuated, it was filled with nitrogen protection, and 0.5g of NH with a molecular weight of 2000 2 -PEG-COOH was dissolved in 20mL of DMF and added to the polymerization tube, according to the LysZ-NCA monomer and CH 3 O-PEG-NH 2 The molar ratio of the LysZ-NCA monomer was added in a ratio of 20:1, and the constant temperature reaction was carried out under nitrogen protection for 24 hours, and then the Leu-NCA monomer and CH 3 O-PEG-NH 2 Add the Leu-NCA monomer at a molar ratio of 40:1, and continue the constant temperature reaction for 48 hours under nitrogen and protection. After the reaction, add 20 times the volume of ether in the reaction system to precipitate, filter, and dry to obtain PEG-PLysZ-PLeu3 block copolymers.

[0126] Dissolve the PEG-PLysZ-PLeu polymer obtained above in trifluoroacetic acid at 0°C, add a HBr...

PUM

| Property | Measurement | Unit |

|---|---|---|

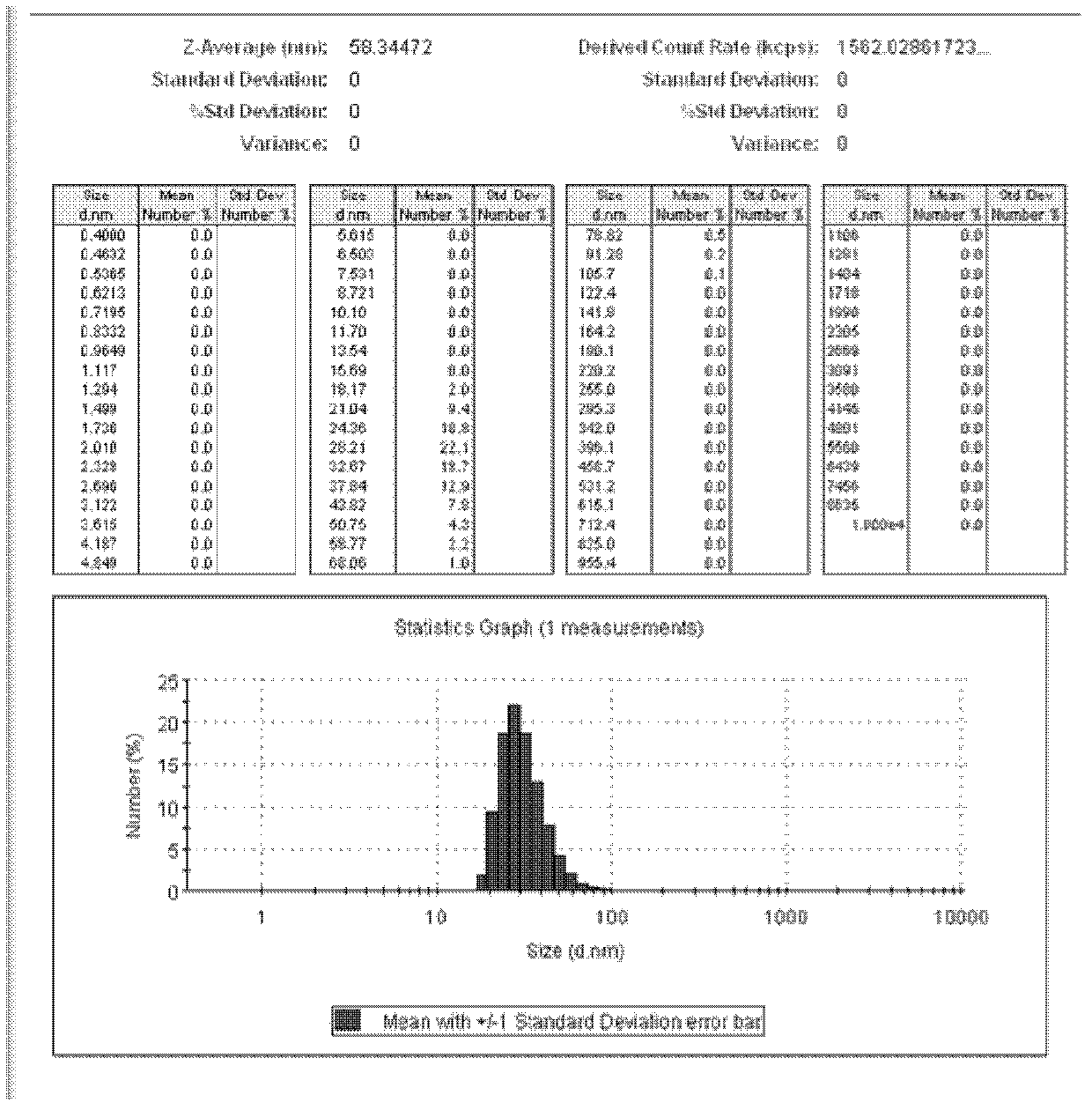

| Particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com