Organic fertilizer prepared from waste edible mushroom culture medium

A technology for preparing culture medium and organic fertilizer, which is applied to organic fertilizer. It can solve the problems of a lot of waste in edible fungi culture medium, low production yield of edible fungi, and no harmless treatment, so as to reduce soil-borne diseases, improve crop nutrition, and reduce the use of pesticides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

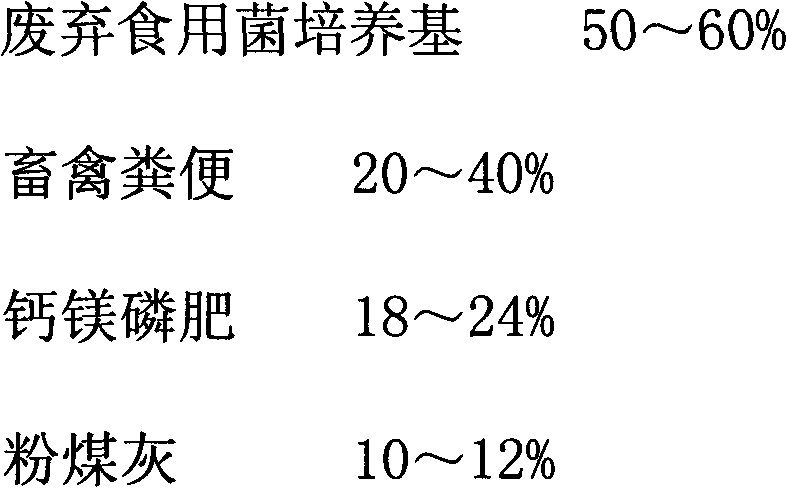

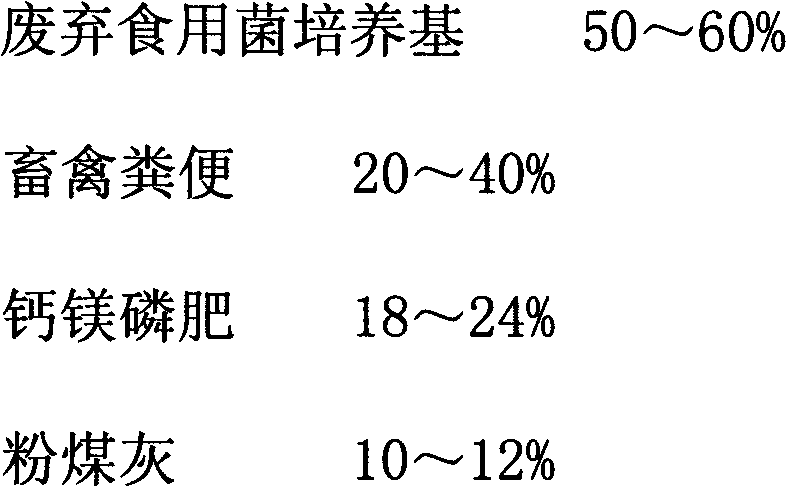

Method used

Image

Examples

Embodiment 1

[0015] Put 20kg of fresh feces and 50kg of waste edible fungus culture medium into a plastic shed to ferment to 50°C and humidity to 50%, and keep it for 18 days; dry the fermented materials, and then crush them with a pulverizer, with a particle size of 2mm. Add calcium magnesium phosphate fertilizer 18kg and fly ash 12kg in the crushed material, the mixed material is granulated by an extrusion granulator, and the particle size is 3mm, which becomes the organic fertilizer of the present invention.

Embodiment 2

[0017] Put 20kg of fresh feces and 50kg of waste edible fungus culture medium into a plastic shed to ferment to 65°C and humidity to 70%, and keep for 26 days; dry the fermented materials, and then crush them with a pulverizer, with a particle size of 1mm. Add calcium magnesium phosphate fertilizer 20kg and fly ash 10kg in the crushed material, the mixed material is granulated by an extrusion granulator, and the particle size is 3mm, which becomes the organic fertilizer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com