PCR (Polymerase Chain Reaction) device based on low-melting-point metal liquid drop and implantation method of PCR device

A metal droplet and reaction device technology, applied in the field of PCR, can solve the problems of increasing the PCR cycle time, poor heat transfer properties, increasing power consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

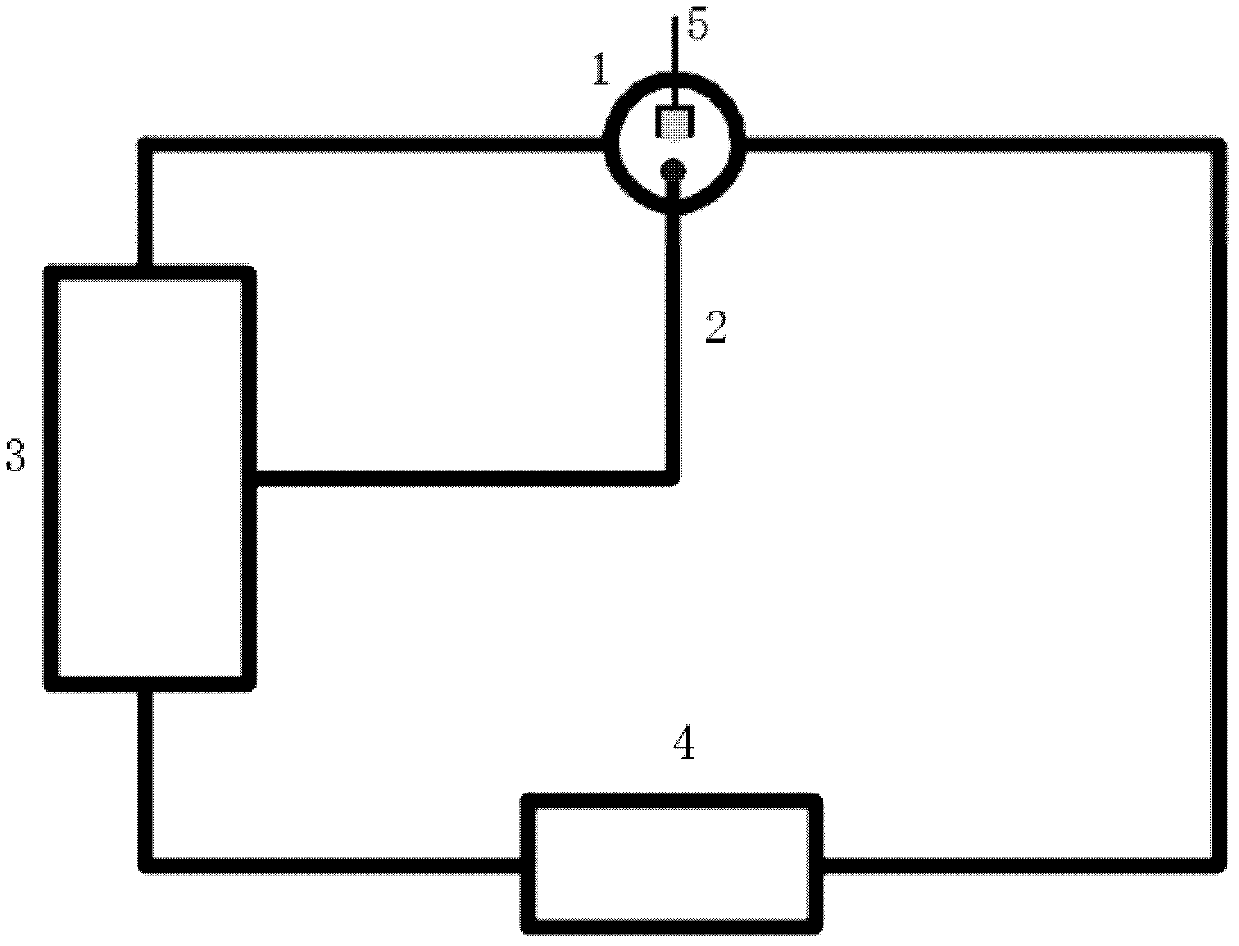

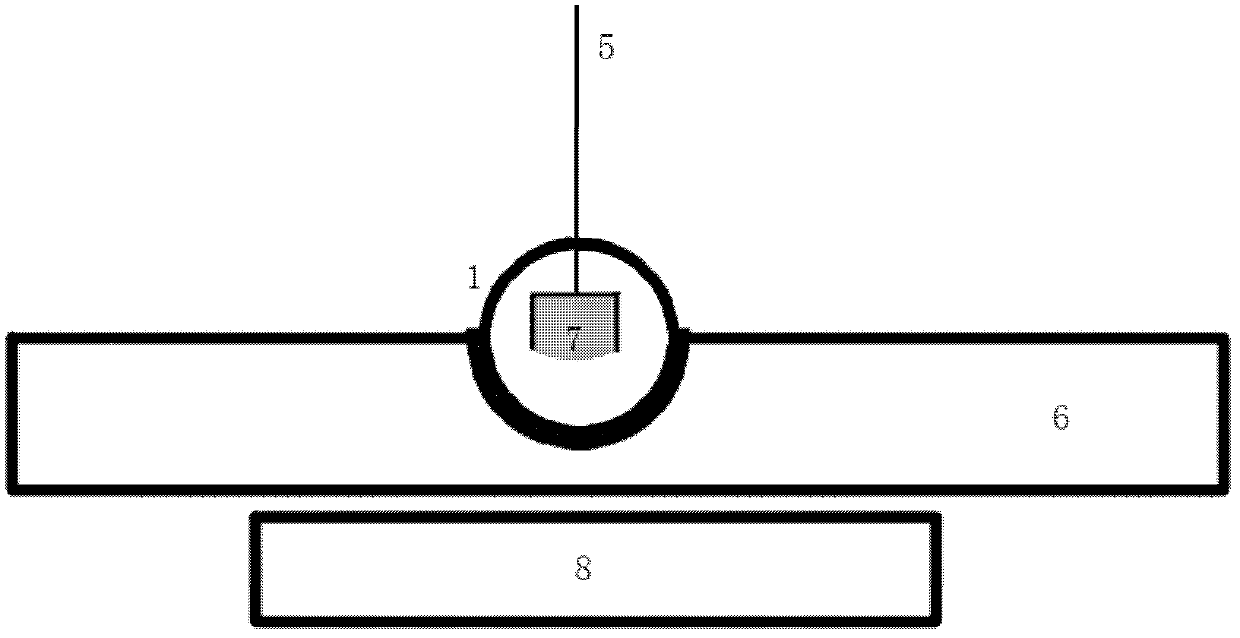

[0043] Such as figure 1 As shown, the metal droplet 1 is connected to the power supply circuit of the power supply 4 as a micro-resistance heater. The micro thermocouple 2 keeps in good contact with the metal droplet 1, and measures the temperature of the metal droplet 1 in real time and feeds it back to the temperature control module 3. The temperature control module 3 contains a temperature feedback part, and adjusts the current through the measured temperature signal to thereby Temperature control is performed by controlling the Joule heat of the metal droplet 1 . The thermocouple 2 can also use a circuit to indirectly measure the temperature of the metal droplet 1 by measuring the change of the resistance value of the metal droplet 1 . The reagent sample 7 that needs to be subjected to PCR reaction temperature cycle is attached to the micro-container 5 by the adhesion of surface tension. In order to prevent the reagent sample from flowing out of the metal droplet 1, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com