A digital spin valve magnetic field sensor and its preparation technology

A magnetic field sensor and spin valve technology, applied in the field of sensor devices, can solve insurmountable problems and achieve the effects of avoiding circuit complexity, signal-to-noise ratio, resolution improvement, and high anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

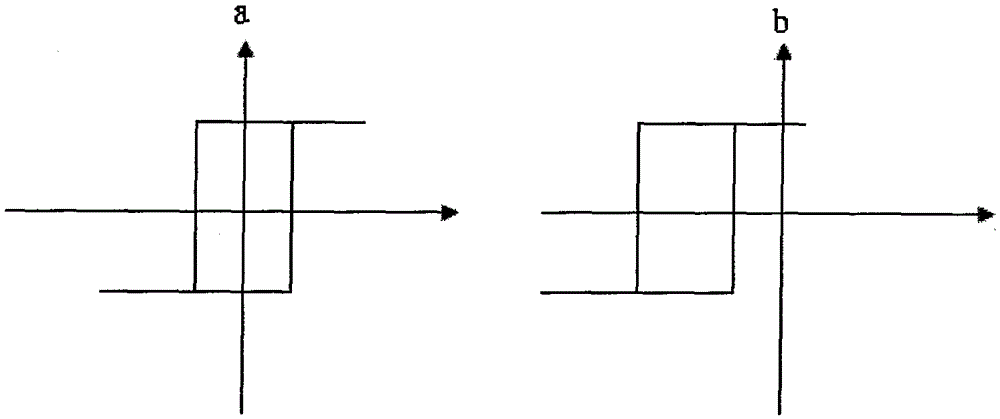

[0027] see Figure 7 , a digital spin valve magnetic field sensor. The giant magnetoresistance spin valve film material structure used on the substrate is composed of multi-layer nanometer-scale thickness giant magnetoresistance and tunnel junction spin valve materials. The core structure is sequentially A buffer layer, an antiferromagnetic layer 4, a first ferromagnetic layer 3, a nonmagnetic layer 2, a second ferromagnetic layer 1 and a protective layer, the first ferromagnetic layer 3 (pinning layer) is continuously variable in thickness wedge.

[0028] The substrate is any substrate material with good flatness such as silicon wafer or glass, and the giant magnetoresistance and tunnel junction spin valve materials are arranged on the substrate by thin film preparation techniques such as magnetron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com