Preparation method of graphite

A technology of graphene and intercalated graphite, which is applied in the field of new material synthesis, can solve the problem of not being able to take into account the high performance and high output of graphene at the same time, and achieve the effect of less defects, good mechanical properties, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

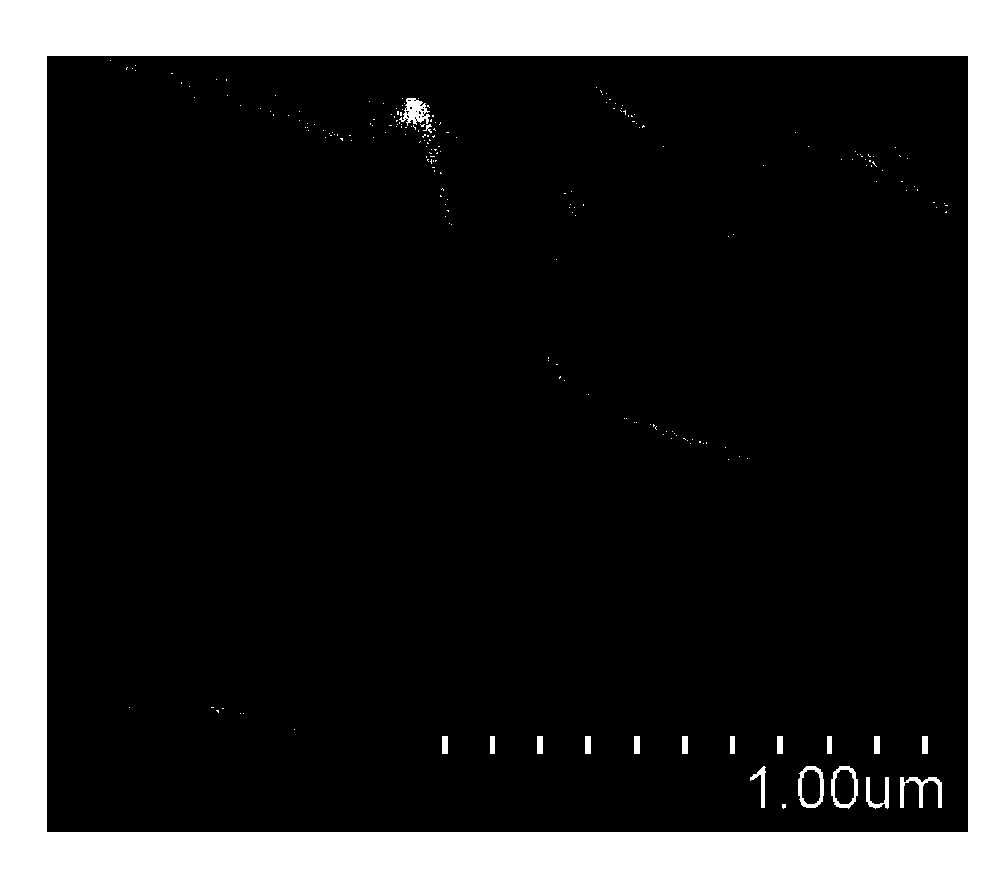

Image

Examples

preparation example Construction

[0015] The preparation method of graphene provided by the invention comprises the following steps:

[0016] (1) Take intercalated graphite and place it in a sealed reactor. The intercalated substance between the intercalated graphite layers is an explosive substance, and the intercalated graphite is added in a ratio of 1 to 5 g / L to the volume of the reactor ;

[0017] (2) Heat the sealed reactor to 280~500°C to cause the explosive reaction to occur. After reaching the heating temperature, keep it for 1~5 minutes, stop heating, cool down, exhaust, and collect the solid product , the solid product is graphene.

[0018] Step (1) is to place the intercalated graphite in which the interlayer intercalated substance is an explosive substance in a sealed environment. The intercalated graphite can be prepared by common chemical or electrochemical methods.

[0019] The operation process of the chemical method is as follows: add natural flake graphite, explosive substances, ferric ch...

Embodiment 1

[0027] A kind of preparation method of graphene, comprises the following steps:

[0028] (1) Take 2g of nitromethane-intercalated graphite, put it in a 1L stainless steel reactor, and then seal the reactor;

[0029] Nitromethane-intercalated graphite is prepared by chemical method, and the preparation process is as follows: the natural flake graphite, nitromethane, ferric chloride and chromium trioxide are mixed according to the mass ratio of 1:3:0.8:0.4, under constant stirring Add it into a three-necked flask equipped with a reflux condensing device and a stirrer, put it in a constant temperature water bath at 60°C, stir and react for 60 minutes, wash until the solution is colorless and the pH value is neutral, filter it with suction, and vacuum at 50°C Dry in a drying oven for 20 hours to obtain nitromethane-intercalated graphite.

[0030] (2) Place the sealed reactor in a heating furnace and heat it to 500°C to cause the nitromethane to react explosively. After keeping it...

Embodiment 2

[0035] A kind of preparation method of graphene, comprises the following steps:

[0036] (1) Take 3g of potassium nitrate-intercalated graphite, put it in a 1L stainless steel reactor, and then seal the reactor;

[0037] Potassium nitrate-intercalation graphite is prepared by electrochemical method, the preparation process is as follows: use stainless steel sheet as current collector, press natural phosphorus flake graphite into 75×40×7mm 3 (about 2g) graphite sheet as the working electrode, lead plate as the counter electrode, Hg / Hg 2 SO 4 As a reference electrode, use a potassium nitrate solution with a concentration of 0.5mol / L as the electrolyte, put the three electrodes into the electrolytic cell and completely soak in the electrolyte, at 20mA / cm 2 The current density, the reaction at room temperature for 24 hours, potassium nitrate-intercalated graphite can be obtained.

[0038](2) Put the sealed reactor in a heating furnace and heat it to 400°C to cause an explosive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com