Method for continuously preparing carboxylic acid ester

A technology of carboxylate and carboxylic acid, which is applied in the field of continuous preparation of carboxylate, can solve the problems of time-consuming, short active operation cycle, low reactivity pollution rate, etc., and achieve the effect of simple method and short purification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

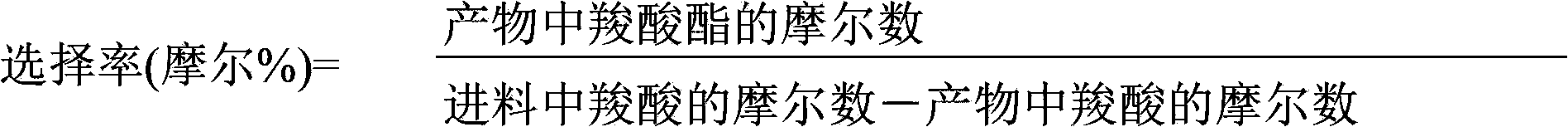

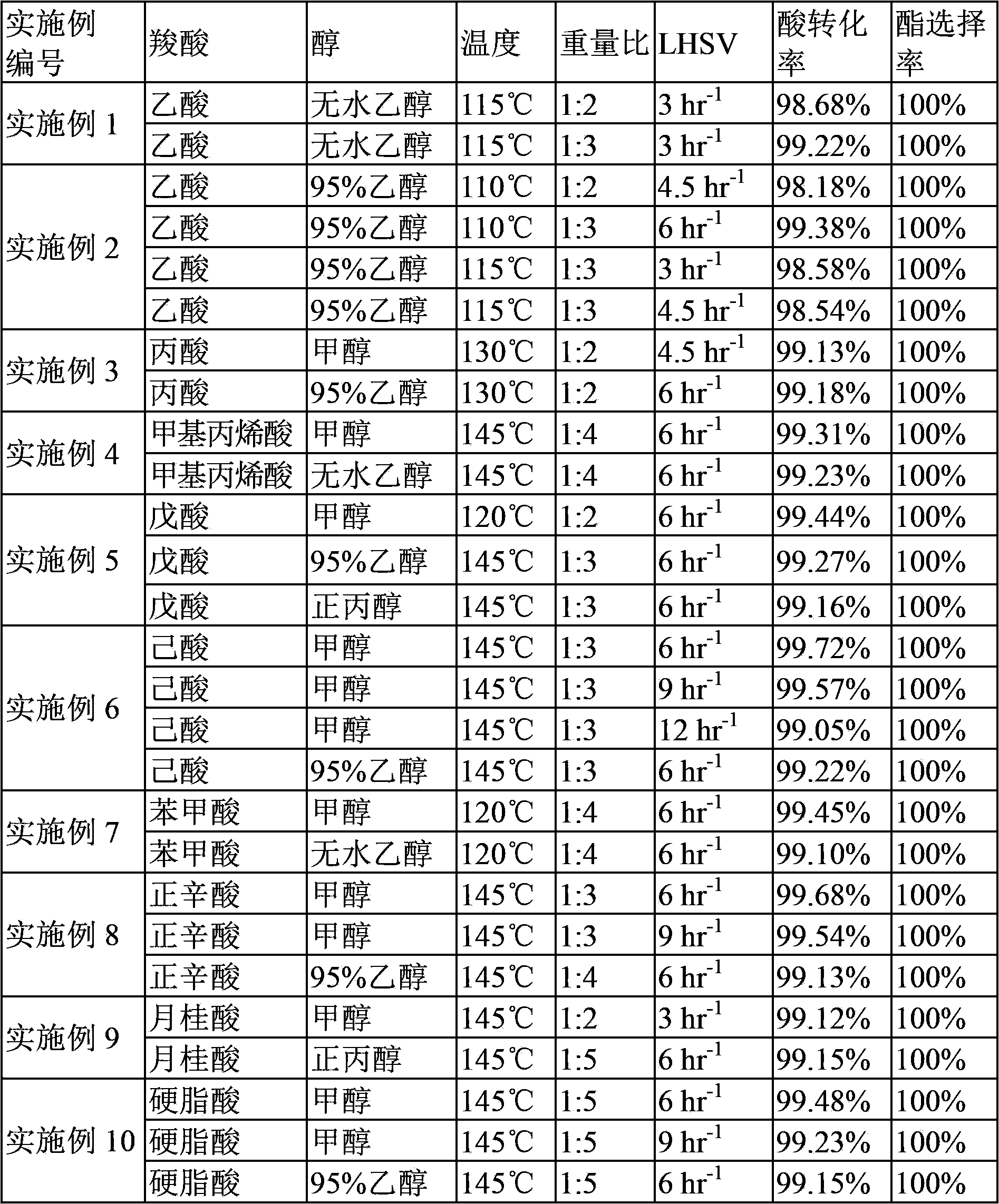

[0019] In the preparation method of the present invention, if the carboxylic acid used is a monocarboxylic acid, the weight ratio of the monocarboxylic acid and alcohol required for the esterification reaction is 1:1 to 1:6, which can be used in the batching tank to The unit carboxylic acid (monocarboxylic acid) and alcohol are mixed at a temperature of 30°C to 80°C, and fed from below the vertical reactor at a rate of 1 to 12 LHSV per hour, and the esterification reaction is carried out at a temperature of 110°C to 190°C.

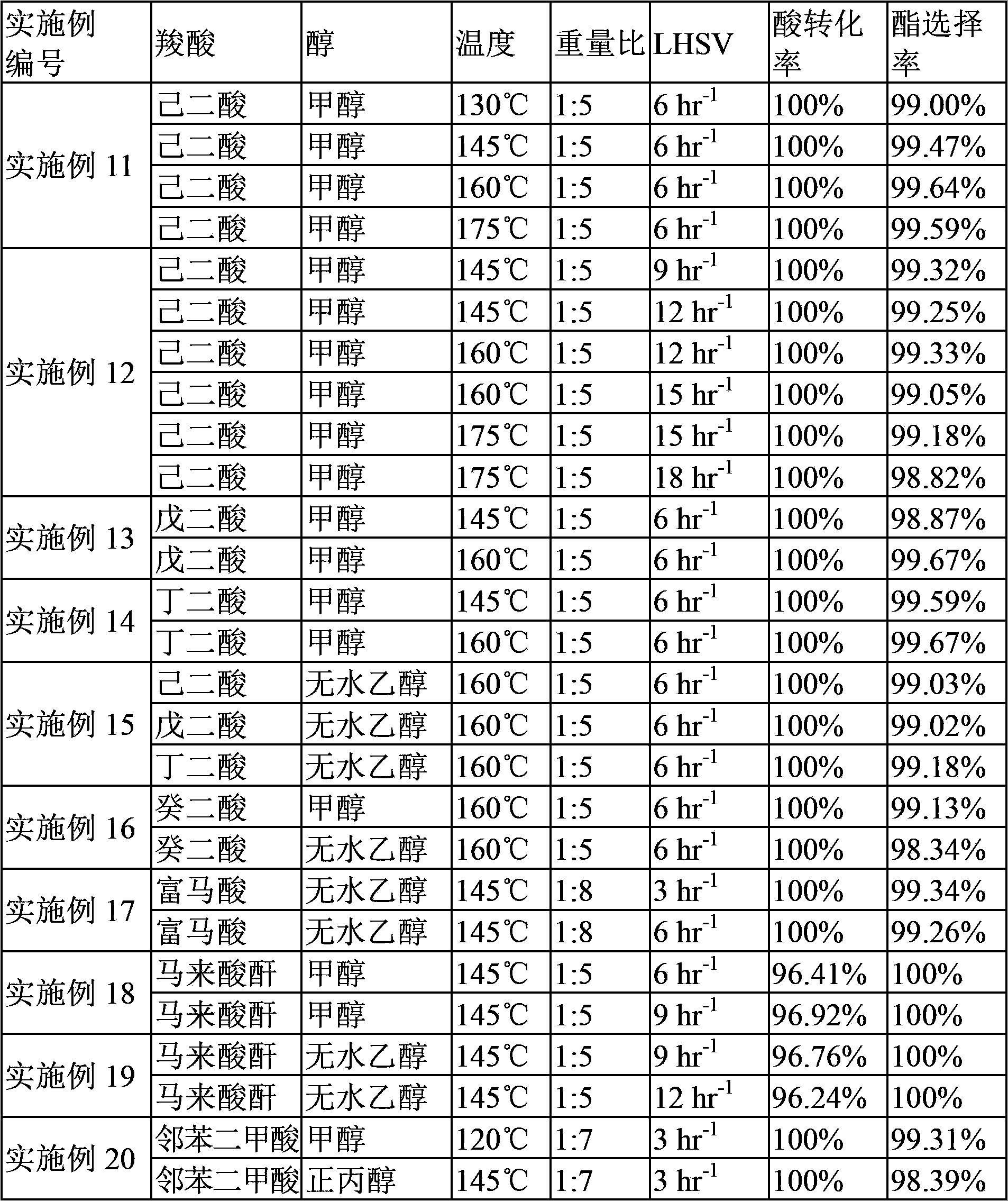

[0020] In another preparation method of the present invention, if the carboxylic acid used is a dibasic carboxylic acid, the weight ratio of the dibasic carboxylic acid and alcohol required for the esterification reaction is 1:3 to 1:10, which can be preceded by The dibasic carboxylic acid and alcohol are mixed at a temperature of 50°C to 75°C in the batching tank, fed from the bottom of the vertical reactor at 2 to 18 LHSV per hour, and esterified at a tem...

Embodiment 1

[0028] Acetic acid and absolute ethanol with a weight ratio of 1:2 or 1:3 were uniformly mixed in a batching tank at 30°C, and then fed from the bottom of the vertical reactor at 3LHSV per hour for reaction, and the reaction temperature was 115°C. The esterification mixture flows out from the upper outlet of the vertical reactor, is collected in a liquid collection bottle and analyzed by a gas chromatograph, and the acid value is determined by titration. The results of conversion and selectivity are listed in Table 1.

Embodiment 2 to 3

[0030] Repeat the operation mode of Example 1, according to the weight ratio shown in Table 1, the carboxylic acid and alcohol are uniformly mixed in the batching tank at 30 ° C, and according to Table 1, they are fed into the reactor from the bottom of the vertical reactor at different speeds, According to Table 1, the reactions were carried out at different reaction temperatures. The measurement results of conversion and selectivity are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com