Emulsified oil for coal mine hydraulic support and preparation method thereof

A coal mine hydraulic and emulsified oil technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of filter blockage, large emulsified oil particle size, affecting the safety of coal mine production, etc., and achieves strong permeability and good lubrication performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An emulsified oil for coal mine hydraulic supports, made of the following raw materials in parts by weight: 3000 parts by weight of water, 200 parts of sodium hydroxide, 300 parts of EDTA, 200 parts of naphthenic acid, 100 parts of phosphoric acid ester, 50 parts of sodium nitrite, 200 parts of triethanolamine, and benzene Triazole 5, A-110 emulsifier 150, glycerin 2000, urea 1500.

[0016] Add water to the reaction kettle, then add sodium hydroxide and EDTA, stir fully to dissolve sodium hydroxide and EDTA completely, then add naphthenic acid, phosphoric acid ester, sodium nitrite, triethanolamine, phenylhydrazine triazole and stir to 70°C until completely dissolved, finally add A-110 emulsifier, glycerin, urea, stir until completely transparent.

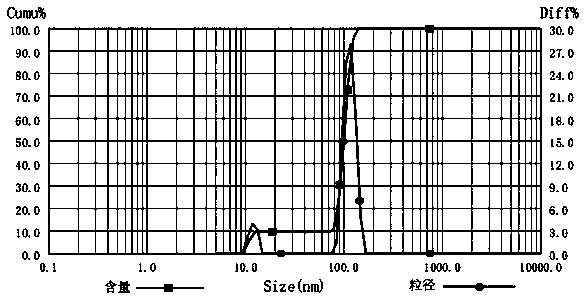

[0017] The particle size of the obtained emulsified oil is 111nm, which cannot be detected on the BT-90 nanometer laser particle size distribution analyzer after emulsification.

Embodiment 2

[0019] An emulsified oil for coal mine hydraulic supports, made of the following raw materials in parts by weight: water 2500, sodium hydroxide 150, EDTA 250, naphthenic acid 150, phosphate ester 50, sodium nitrite 20, triethanolamine 150, benzo Triazole 1, A-110 emulsifier 100, glycerin 1500, urea 1000.

[0020] Add water to the reaction kettle, then add sodium hydroxide and EDTA, stir fully to dissolve sodium hydroxide and EDTA completely, then add naphthenic acid, phosphoric acid ester, sodium nitrite, triethanolamine, phenylhydrazine triazole and stir to 70°C until completely dissolved, finally add A-110 emulsifier, glycerin, urea, stir until completely transparent.

[0021] The particle size of the obtained emulsified oil is 111nm, which cannot be detected on the BT-90 nanometer laser particle size distribution analyzer after emulsification.

Embodiment 3

[0023] An emulsified oil for coal mine hydraulic supports, made of the following raw materials in parts by weight: water 2852, sodium hydroxide 177, EDTA 289, naphthenic acid 185, phosphate ester 86, sodium nitrite 39, triethanolamine 174, benzo Triazole 4, A-110 emulsifier 145, glycerin 1731, urea 1355.

[0024] Add water to the reaction kettle, then add sodium hydroxide and EDTA, stir fully to dissolve sodium hydroxide and EDTA completely, then add naphthenic acid, phosphoric acid ester, sodium nitrite, triethanolamine, phenylhydrazine triazole and stir to 70°C until completely dissolved, finally add A-110 emulsifier, glycerin, urea, stir until completely transparent.

[0025] The emulsified oil particle diameter that obtains is 111nm, detects on the BT-90 nanometer laser particle size distribution instrument after emulsification, obtains as follows figure 1 The particle size distribution diagram of the emulsified oil shown has strong permeability and will not block the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com