Preparation method of porous carbon material based on ionic heat process

A porous carbon, ionothermal technology, applied in the preparation/purification of carbon, to achieve excellent self-template porosity, low energy consumption, and good chemical and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The structure of the ionic liquid used in this example is shown in the following formula (IL-a):

[0029]

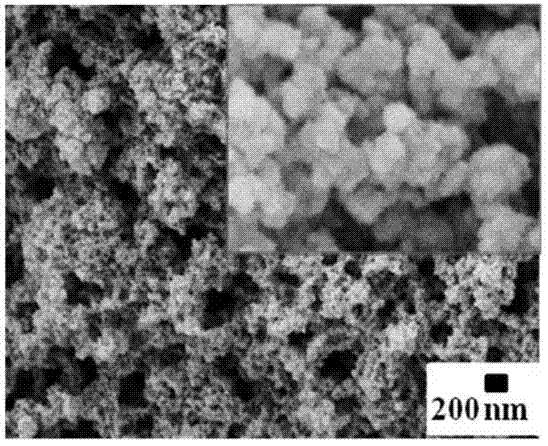

[0030] Add 1g of sucrose and 10ml of ionic liquid (IL-a) into a 50ml beaker, heat slowly and stir to dissolve. The resulting solution was transferred to a reaction kettle, heated to 160°C, and reacted for 12 hours. After the reaction is finished, the product is washed with distilled water, then suction-filtered, and the corresponding porous carbon material is obtained after drying. The scanning electron microscope image of the obtained porous carbon material is shown in figure 1 , the product is an irregular massive structure. The specific surface area of the product is less than 10m 2 / g, indicating that [Bmim][FeCl 3 ] The high specific surface area carbon material obtained as a solvent should be considered as an iron-catalyzed carbonization process, and its pore-forming mechanism is completely different from the ionothermal process of the present inven...

Embodiment 2

[0032] The structure of the ionic liquid used in this example is shown in the following formula (IL-b):

[0033]

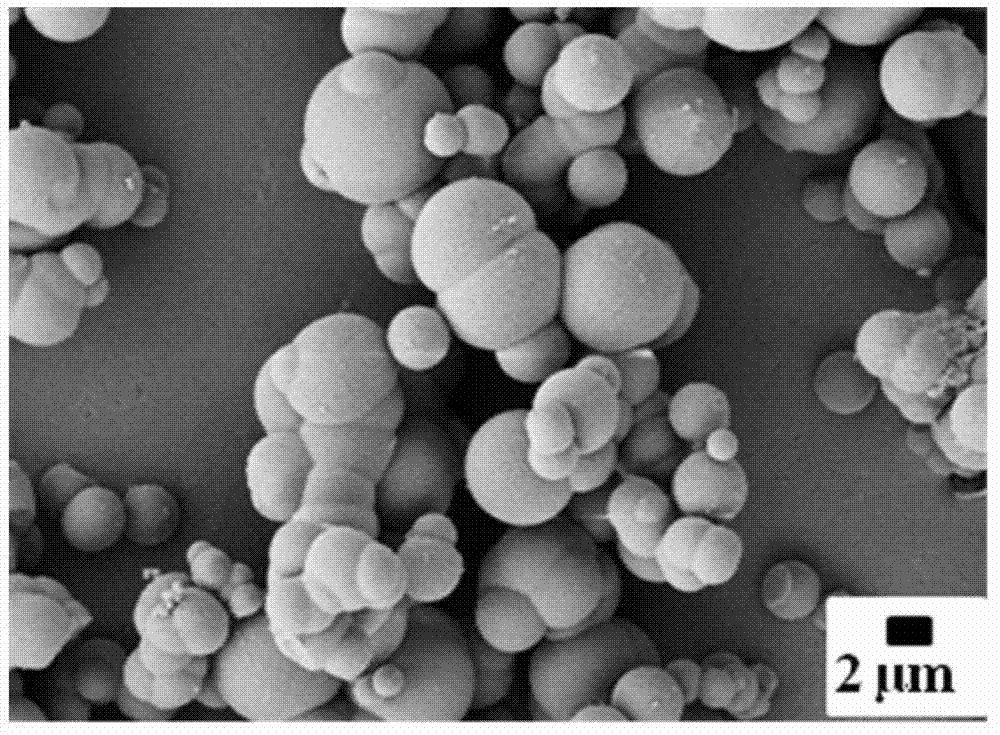

[0034] Add 3g fructose and 20ml ionic liquid (IL-b) into a 25ml beaker, stir to dissolve. The resulting solution was transferred to a reaction kettle, heated to 230 degrees, and reacted for 32 hours. After the reaction is finished, the product is washed with distilled water, then suction-filtered, and the corresponding porous carbon material is obtained after drying. The scanning electron microscope image of the porous carbon material is shown in figure 2 As shown, the product has a micron-scale spherical structure from the analysis of the results of the electron microscope, and the diameter of the carbon sphere is about 2-5 microns, see below figure 2 . The specific surface area of its products is 26m 2 / g. Compared with Example 1, it can be concluded that the ionic liquid used has a great influence on the morphology of the product, and only increasing...

Embodiment 3

[0036] The structure of the ionic liquid used in this example is shown in the following formula (IL-c):

[0037]

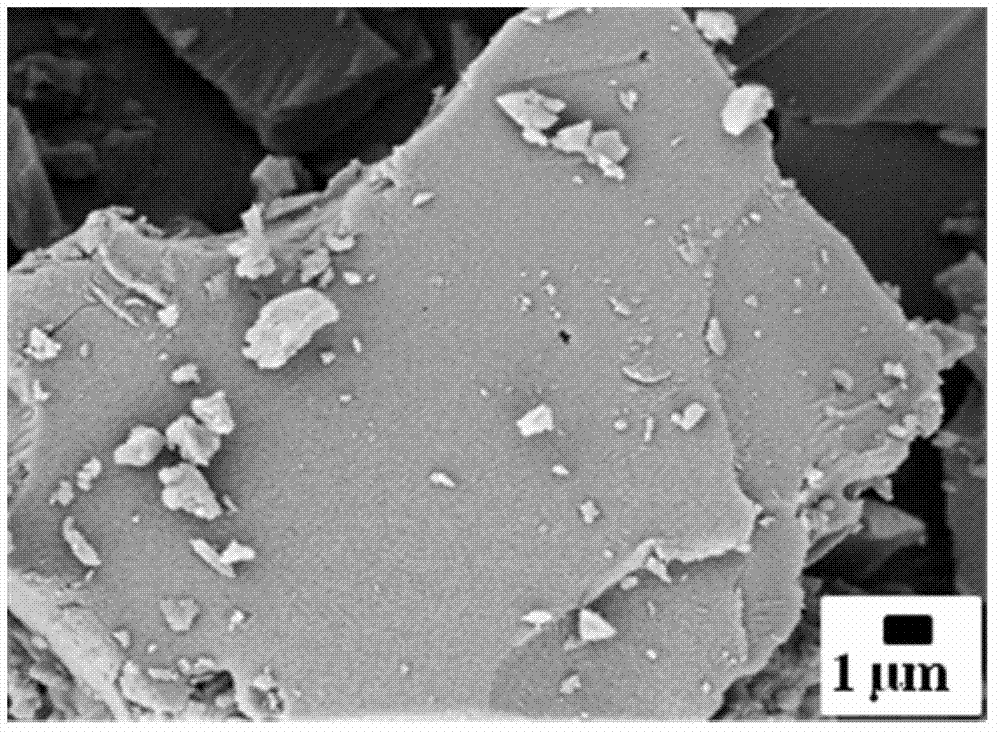

[0038] Add 6g of cellulose and 15ml of ionic liquid (IL-c) into a 50ml beaker, stir to dissolve. The resulting solution was transferred to a reaction kettle, heated to 170°C, and reacted for 18 hours. After the reaction is finished, the product is washed with distilled water, then suction-filtered, and the porous carbon material is obtained after drying. The transmission electron microscopy results of the porous carbon material are as follows: image 3 As shown, the product is composed of 50-150nm carbon spheres analyzed from the electron microscope results. The carbon material was subjected to 77K low-temperature nitrogen adsorption test, as shown in Figure 4 , indicating that the specific surface area of the obtained product can reach 117m 2 / g. By comparing with Example 2, it can be found that the type of ionic liquid solvent has a decisive influence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com