Iron runner casting material using waste alumino-silicon-carbide carbon bricks as aggregate

A technology for silicon carbide carbon bricks and castables for iron trenches is applied in the field of indeterminate refractories, which can solve the problems affecting the use performance of waste aluminum silicon carbide carbon bricks, the performance of castables needs to be improved, the utilization rate of waste materials is low, and the like. Excellent physical properties, reduce the production of low melt phase, and reduce the effect of overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

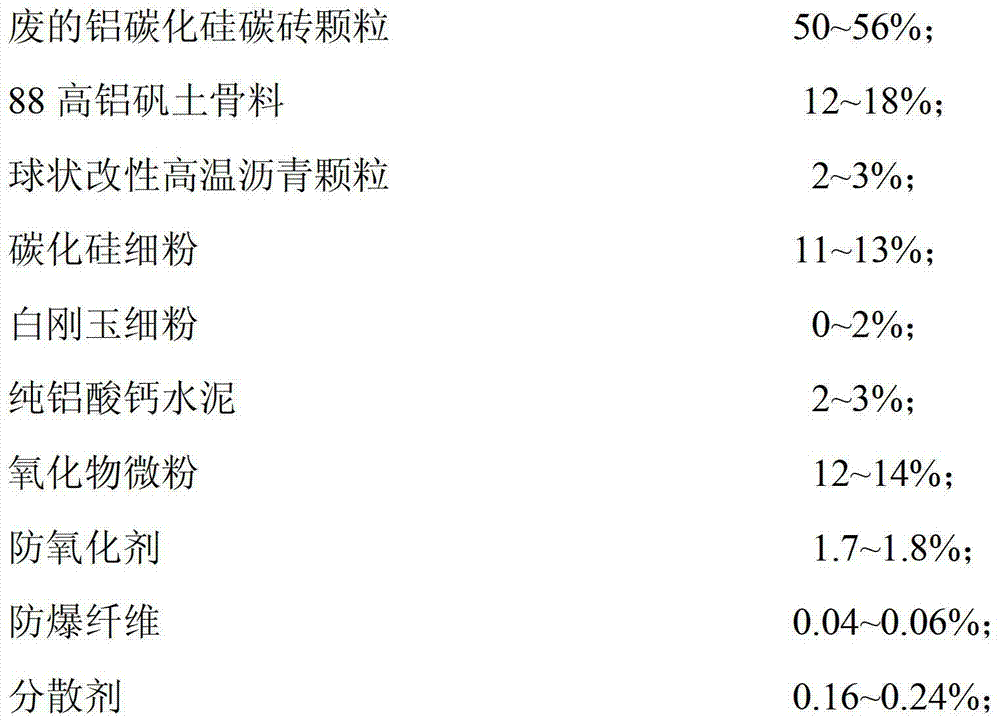

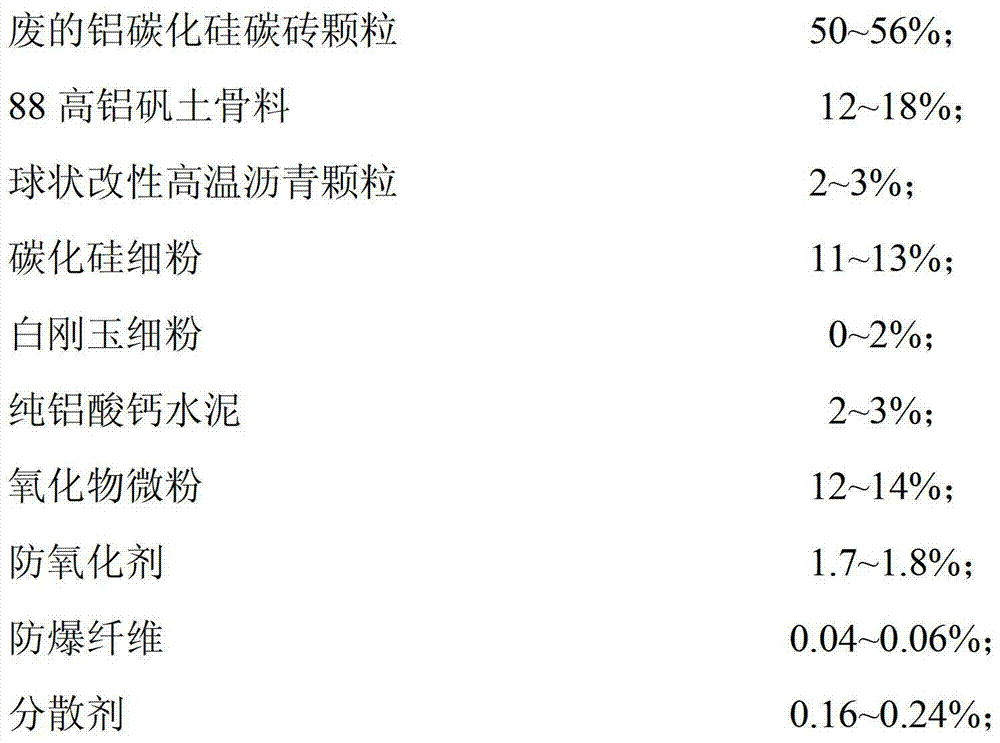

Embodiment 1

[0015] A kind of iron channel castable with waste aluminum silicon carbide carbon brick as aggregate, 50% (weight percentage, the same below) waste aluminum silicon carbide carbon brick particles, 18% 88 high alumina bauxite aggregate, 2% spherical modified high-temperature asphalt particles, 12% silicon carbide fine powder, 1% white corundum fine powder, 2% pure calcium aluminate cement, 13% oxide fine powder (of which: 10% alumina fine powder and 3% of silica powder), 1.8% of antioxidant (of which: 1.75% of metal silicon powder and 0.05% of metal aluminum powder), 0.04% of explosion-proof fiber, 0.16% of dispersant (of which: 0.08% of poly Carboxylic acid and 0.08% polyethylene glycol) are fully mixed; add 6.6% water of the total weight of the castable, stir evenly and vibrate to form. The molded samples were dried naturally for 24 hours and then heat-treated at 110°C for 24 hours to prepare iron trench castable samples with waste aluminum silicon carbide carbon bricks as ag...

Embodiment 2

[0021] A kind of iron channel castable with waste aluminum silicon carbide carbon brick as aggregate and its preparation method, 53% (weight percentage, the same below) of waste aluminum silicon carbide carbon brick particles, 14% of 88 high alumina bauxite Aggregate, 3% spherical modified high-temperature asphalt particles, 13% silicon carbide powder, 3% pure calcium aluminate cement, 12% oxide micropowder (of which: 10% alumina micropowder and 2% silica powder), 1.75% antioxidant (of which: 1.7% metal silicon powder and 0.05% metal aluminum powder), 0.05% explosion-proof fiber (polypropylene fiber), 0.2% dispersant (of which: 0.1% polycarboxylate Acid and 0.1% polyethylene glycol), fully mixed, add 6.8% water of the total weight of the castable, stir evenly and vibrate to form. The molded samples were dried naturally for 24 hours and then heat-treated at 110°C for 24 hours to prepare iron trench castable samples with waste aluminum silicon carbide carbon bricks as aggregates...

Embodiment 3

[0026] A kind of iron channel castable with waste aluminum silicon carbide carbon brick as aggregate and its preparation method, 56% (weight percentage, the same below) waste aluminum silicon carbide carbon brick particles, 12% 88 high alumina bauxite Aggregate, 2% spherical modified high-temperature asphalt particles, 12% silicon carbide fine powder, 2% white corundum fine powder, 2% pure calcium aluminate cement, 12% oxide fine powder (of which: 9% Aluminum oxide fine powder and 3% silicon oxide fine powder), 1.7% antioxidant (of which: 1.65% metal silicon powder and 0.05% metal aluminum powder), 0.06% explosion-proof fiber (polypropylene fiber), 0.24% dispersion Agents (among them: 0.12% polycarboxylic acid and 0.12% polyethylene glycol) are fully mixed, and 6.8% of the total weight of the castable is added to the water, stirred evenly, and vibrated to form. The molded samples were dried naturally for 24 hours and then heat-treated at 110°C for 24 hours to prepare iron tren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature flexural strength | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Room temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com