Preparation method for epitaxial germanium film through polymer auxiliary deposition

An assisted deposition and germanium thin film technology, which is applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve problems such as complex and expensive methods, and achieve highly ordered lattice mismatch and good epitaxial film quality , the effect of good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

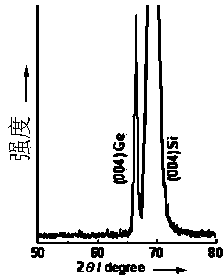

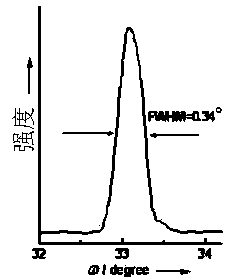

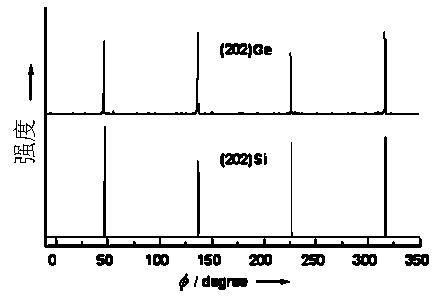

[0032] The invention directly prepares a highly ordered germanium thin film on a single crystal silicon substrate without a buffer layer. The preparation method applies a germanium-containing coating solution to a silicon substrate. Then place the coated substrate in a hydrogen atmosphere for heat treatment, and directly transform it into a high-quality lattice-mismatched highly ordered germanium film on the silicon substrate.

[0033] The specific coating solution is obtained by mixing water, germanium compound, polyethylenediamine (PEI) and ethylenediaminetetraacetic acid (EDTA) to prepare a precursor solution, and then ultrafiltering it. For example: Add 2.5 g EDTA (ALDRICH, 99.995%) to 25 ml pure water (resistance value 18 MΩ, prepared by MILLI-Q system). Add 1.26 g of high-purity germanium oxide (ALDRICH, 99.99%), and then add 4 g of polyethylenediamine (PEI) (BASF, Germany). The final solution was subjected to ultrafiltration using an ultrafiltration cup (AMICON) sti...

Embodiment A

[0047] Prepare coating solution using germanium oxide: 2.56 g H 2 EDTA (Aldrich, 99.995%) was dissolved in 25 mL of water, and 3.25 g of polyethylenediamine (PEI,) (BASF, Germany) was added and mixed until a clear liquid was formed. Then add 1.20 g GeO 2 (ACROS, 99.999%). After stirring overnight, a clear solution with some precipitate was obtained. The precipitate was removed by filtration (0.45 μm filter). The obtained clear filtrate was diluted to 200 mL, and placed in an ultrafiltration cup for ultrafiltration to remove impurities with a molecular weight below 10,000 g / mol. It was then concentrated to 20 mL. The concentration of germanium contained in the coating solution obtained by inductively coupled plasma atomic emission (ICP-AES) spectrometer test is 404 mM, and the pH value is 8.44.

Embodiment B

[0049] Prepare coating solution using germanium tetrachloride: 1.3 g H 2 EDTA (Aldrich, 99.995%) was dissolved in 25 mL of water, and 1.6 g of polyethylenediamine (PEI,) (BASF, Germany) was added and mixed until a clear liquid was formed. Then slowly add 1.20 g GeCl 4 (ACROS, 99.999%). A small amount of precipitation will occur. The pH was adjusted to 4.9 by dropwise addition of aqueous ammonia, and the solution was left overnight. A solution with a little precipitate was obtained. The precipitate was removed by filtration (0.45 μm filter). The germanium concentration in the obtained clarified solution is 200 mM, and it can also be directly used as a coating solution, because the residual ammonium and chlorine will be removed during the membrane annealing process. Further purification to remove ammonium chloride is to remove impurities with a molecular weight lower than 10000 g / mol by placing the clarified liquid obtained above in an ultrafiltration cup for ultrafiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com