Preparation method of ionic liquid-doped conductive nanofiber

A nanofiber and ion-doped technology, which is applied in spinning solution preparation, conductive/antistatic filament manufacturing, fiber treatment, etc., can solve the difficulties of conducting polymer nanofibers, reduce the conductivity of composite nanofibers, and lower the viscosity of the solution and other issues, to achieve the effect of easy operation and repetition, low cost, good electrical conductivity and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

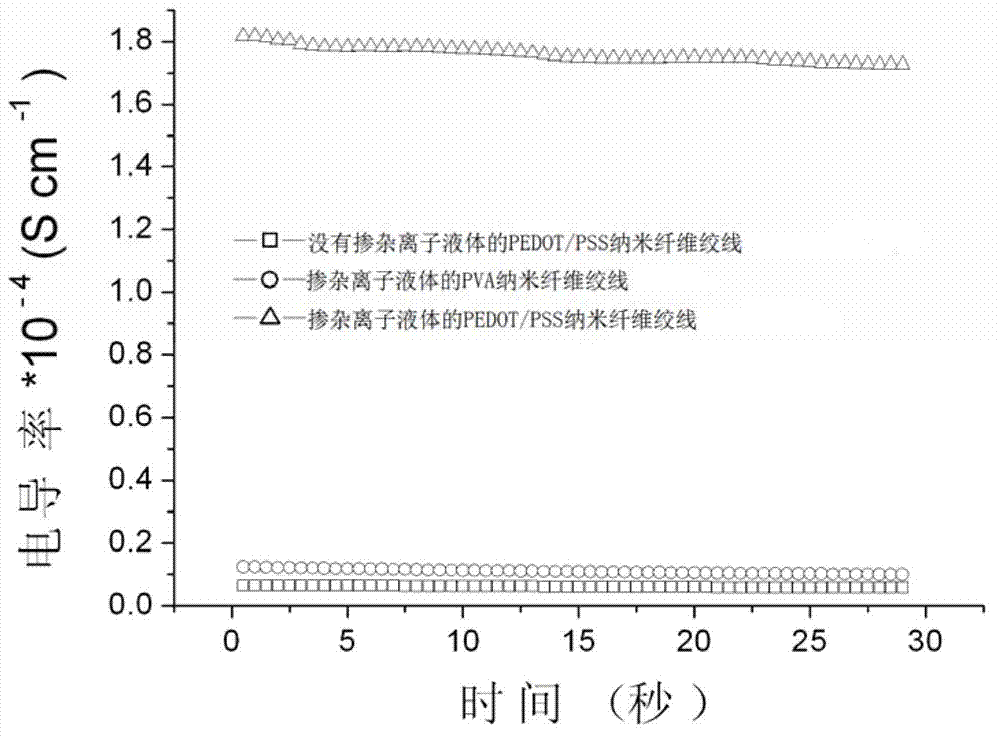

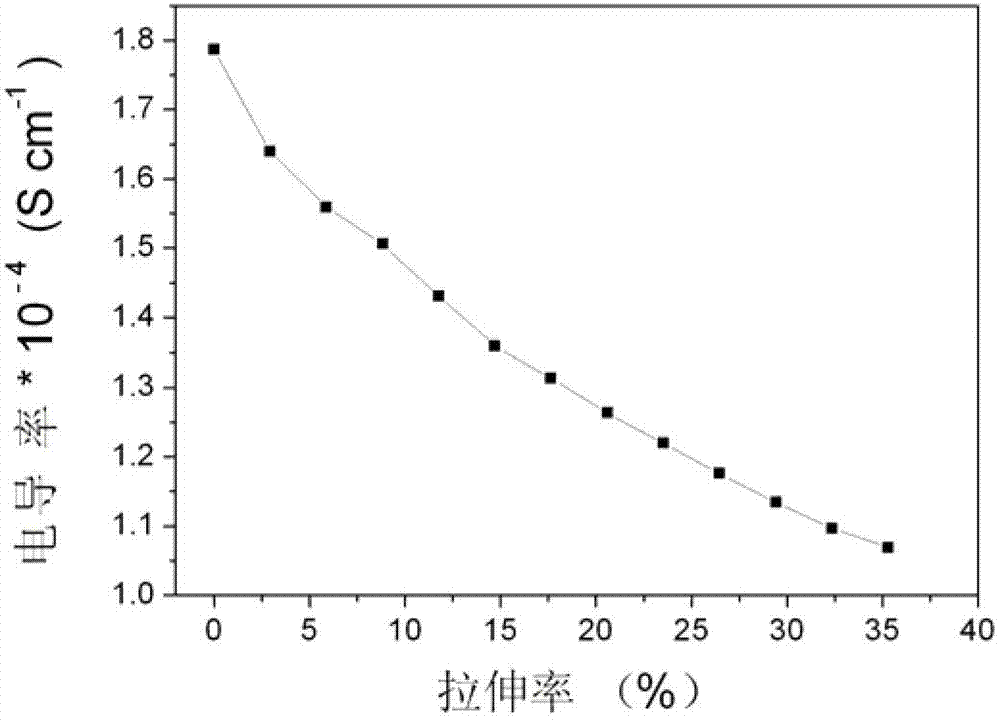

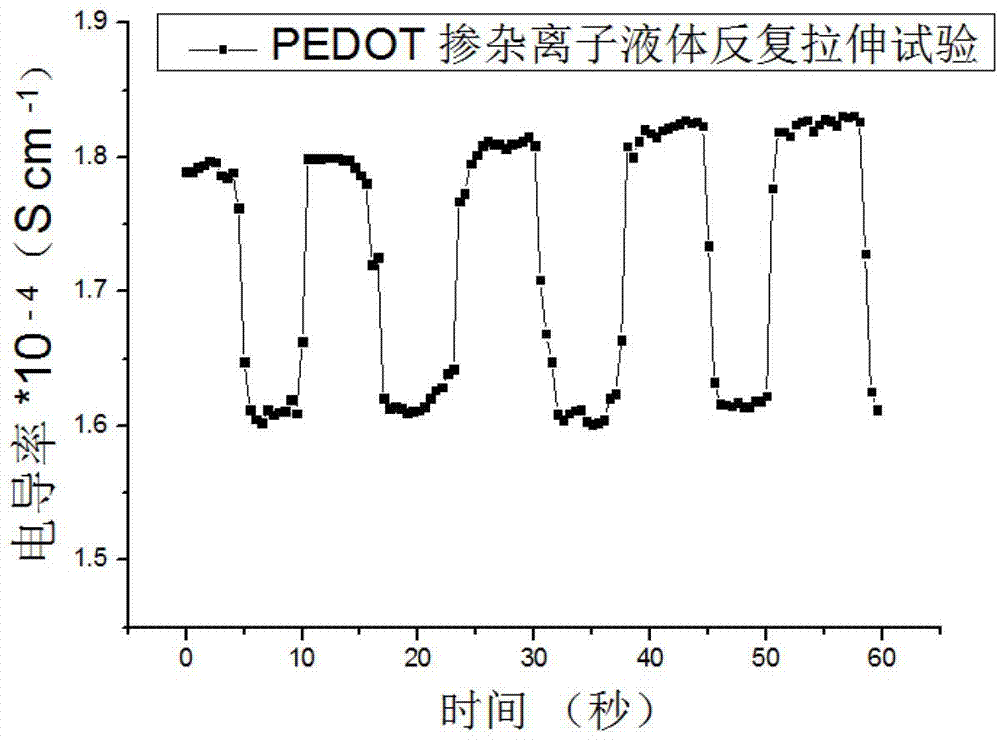

[0015] This embodiment includes three steps of precursor spinning solution preparation, nanofiber preparation and conductivity test, and its specific process is:

[0016] (1) Precursor spinning solution preparation: First, add polyethylenedioxythiophene / polystyrene sodium sulfonate (PEDOT / PSS) aqueous solution with a concentration of 2.8% by mass to the conical flask with a disposable straw Water and ethanol, after stirring evenly, add polyvinyl alcohol (PVA) into the Erlenmeyer flask, heat and stir in a water bath on an existing magnetic heating mixer for 1 hour, the obtained solution is a viscous black-blue liquid, and then The obtained solution and ionic liquid 1-ethyl-3-methylimidazole acetate are added into ionic liquid 1-ethyl-3-methylimidazole acetate in a ratio of 30-70:1 according to the mass ratio at room temperature After stirring for 1 hour, a dark blue viscous polyethylenedioxythiophene / polystyrene sodium sulfonate (PEDOT / PSS) precursor spinning solution doped wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com