Activation method and application of biomass liquefaction residue

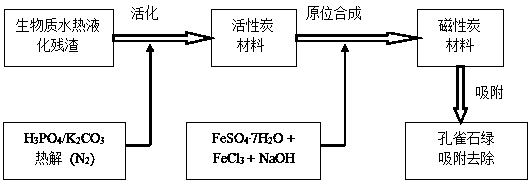

A technology of liquefaction residue and activation method, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of no adsorption effect, low specific surface area, difficult separation and recovery, etc., and achieve the effects of easy magnetic separation, simple preparation process, and avoidance of resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

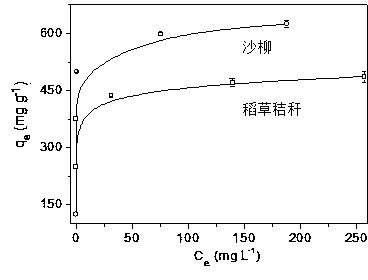

[0017] (1) Dry Salix salix biomass hydrothermal liquefaction residue, sieve 20 mesh; add the sieved residue to K 2 CO 3 Soak in aqueous solution for 24 hours, dry, the material and K 2 CO 3 The mass ratio is 1:2. Put the dried biochar material into the porcelain week, put it in a high-temperature box furnace, and raise the temperature to 700°C at a rate of 4°C / min under the protection of nitrogen atmosphere, and maintain it for 90min. After the temperature is cooled to room temperature, take it out, wash with water, and dry to obtain activated carbon particles AC-1. Measured by the specific surface area measuring instrument, its specific surface area is 1230m 2 / g, the pore volumes of total pores and micropores are 0.81 and 0.55cm 3 g -1 .

Embodiment 2

[0019] (2) Dry rice straw biomass hydrothermal liquefaction residue, sieve 20 mesh; add the sieved residue to K 2 CO 3 Soak in aqueous solution for 24 hours, dry, the material and K 2 CO 3 The mass ratio is 1:2. Put the dried biochar material into the porcelain week, put it in a high-temperature box furnace, and raise the temperature to 700°C at a rate of 4°C / min under the protection of nitrogen atmosphere, and maintain it for 90min. After the temperature is cooled to room temperature, take it out, wash with water, and dry to obtain activated carbon particles AC-2. Measured by the specific surface area measuring instrument, its specific surface area is 1334m 2 / g, the pore volume of total pores and micropores is 1.07 and 0.50cm 3 g -1 .

Embodiment 3

[0021] Activated carbon particles AC-1, sieved to 20 mesh, added to the iron salt solution, the mass ratio of activated carbon to iron oxide is 1:1, and the iron salt solution is FeCl 3 and FeSO 4 . 7H 2 For the mixed solution of O, the molar ratio is preferably 1:1. Under a water bath at 70°C, 100 mL of 5 mol / L NaOH solution was added dropwise with stirring, and aged for 3 hours. After the solid material is filtered, washed with water and dried, the magnetic carbon material M-1 is obtained. Measured by the specific surface area measuring instrument, its specific surface area is 673m 2 / g, the pore volumes of total pores and micropores are 0.65 and 0.28cm 3 g -1 . The prepared magnetic carbon material was measured by a vibrating sample magnetometer, and the saturation magnetic strength was 38.5 emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com