Single-excitation ultrasonic oval vibration energy converter

A technology of elliptical vibration and ultrasonic vibration, which is applied in the direction of fluid using vibration, can solve the problems that restrict the application and promotion of ultrasonic elliptical vibration transducers, the complex structure of ultrasonic vibration system and control system, and affect the cutting effect of ultrasonic elliptical vibration. To achieve the effect of simplifying the control circuit and ultrasonic power supply structure, simple structure and stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

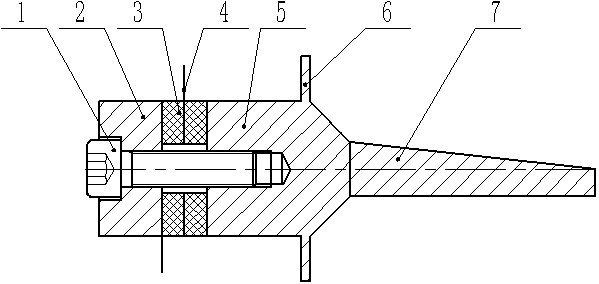

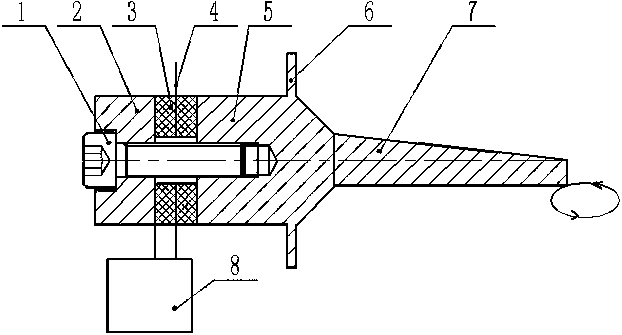

[0016] combine figure 1 , 2 As shown, the single-excitation ultrasonic elliptical vibration transducer includes an ultrasonic vibration transducer and an elliptical vibration mode converter 7. The outer contour of the ultrasonic vibration transducer is cylindrical, which includes a bolt 1 and is sleeved on the bolt 1 in turn. The rear cover 2, the piezoelectric ceramic sheet 3, the electrode sheet 4 and the front cover 5, the front cover is provided with a flange 6 that can be connected with the external structure, the rear cover 2 and the front cover 5 are connected by bolts 1 The rear cover 2, the piezoelectric ceramic sheet 3, the electrode sheet 4 and the front cover 5 are connected and compressed to form the energy conversion part of the single-excitation ultrasonic elliptical vibration transducer, which can convert the ultrasonic electric energy output by the ultrasonic power supply 8 is the ultrasonic vibration energy of the ultrasonic vibration transducer, the single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com