Coating material for lithium ion battery diaphragm

A technology for lithium-ion batteries and coating materials, applied in coatings, battery pack components, circuits, etc., can solve the problems of poor electrolyte wettability, poor thermal stability, battery safety problems, etc., and achieve easy production. Control and promotion, the process method is simple and easy to implement, and the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

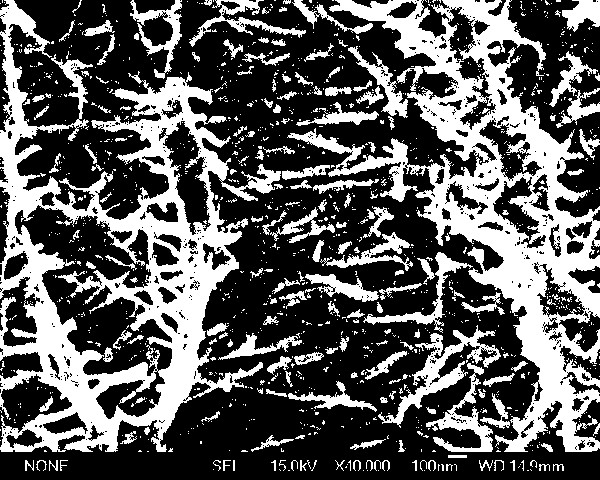

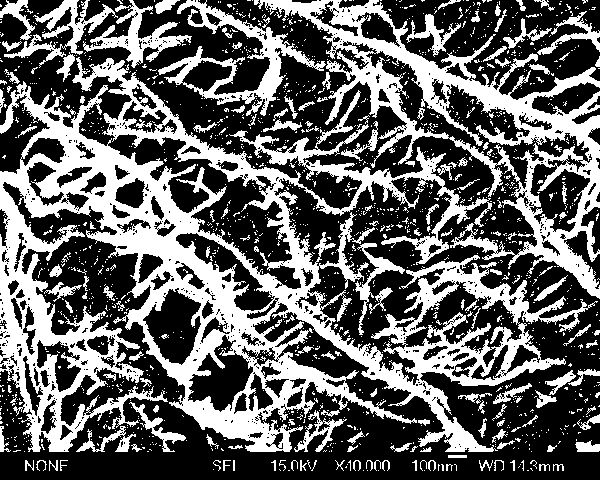

Image

Examples

Embodiment 1

[0034] Example 1: SiO with a particle size of about 10 nm 2 Nanoparticles 3.0g, PVDF 0.9g, γ-(methacryloxy)propyltrimethoxysilane 0.3g, catechol 0.1g, acetone 200g. High-speed shearing and mixing for 2 hours, and then coating on a single-layer polypropylene diaphragm by dip coating. In the process of dip coating and film formation, the time interval between each dip coating is 240s, and the residence time after immersion is 10s. Repeat dip coating 3 times, and then dry at 50°C for 1 min. The coating amount is about 3 g / m 2 .

Embodiment 2

[0035] Example 2: TiO with a particle size of about 30 nm 2 Add 5.0 g of nanoparticles, 6.0 g of polyvinylpyrrolidone, and 0.4 g of glycolic acid to 200 g of methanol, mix ultrasonically for 0.5 h, and then form a film on a single-layer polyethylene diaphragm by dip coating. In the process of dip coating and film formation, the time interval between each dip coating is 240s, the residence time after dipping is 10s, and it is dried at 50°C for 1min. Repeat dip coating twice, then dry at 50°C for 1 min, the coating amount is about 4 g / m 2 .

Embodiment 3

[0036] Embodiment 3: the particle diameter is about 15 nm ZrO 2 Add 13.4g of nanoparticles, 11.2g of PVDF-HFP, 1.6g of diethanolamine, and 0.8g of water into a mixed solvent of 60.0g of methanol and 100.0g of acetone, mix ultrasonically for 0.5h, and then Pick A film was formed on a single-layer polyethylene separator by dip coating. The time interval between each dip coating is 240s, the residence time after immersion is 10s, and it is dried at 50°C for 2 minutes. Repeat the dip coating twice, then dry at 50°C for 1 min, the coating amount is about 3 g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com