Environment-friendly waterborne fire retardant coating

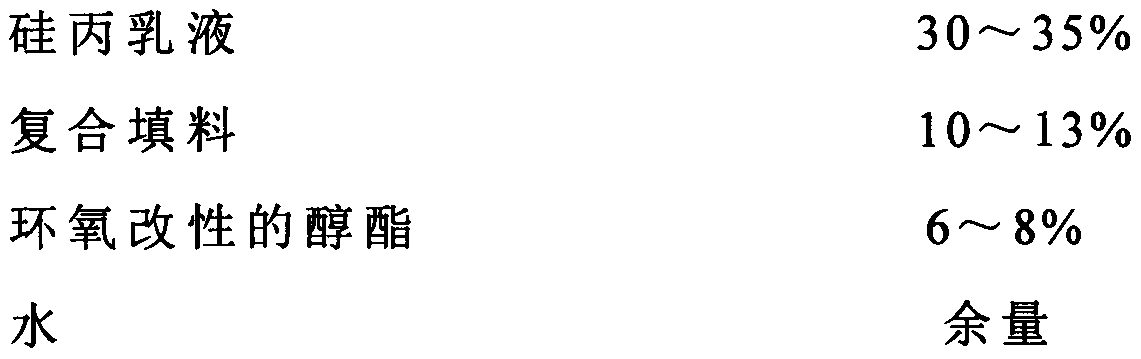

A flame retardant coating and water-based technology, applied in the field of building decoration materials, can solve the problems of reducing the environmental protection of water-based coatings, poor compatibility of organic components, poor flame retardant effect of flame retardants, etc., to achieve enhanced film-forming effect and high adhesion. The effect of stability and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

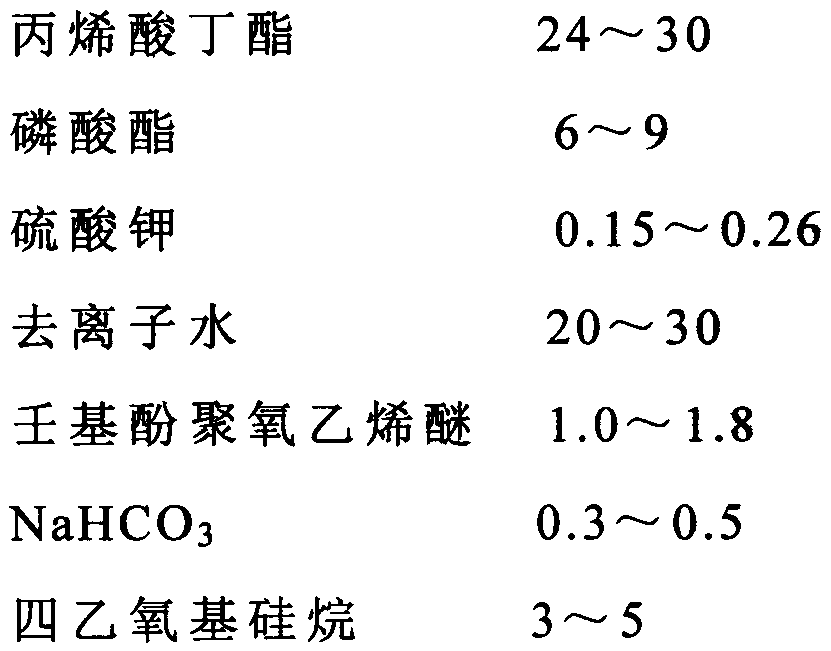

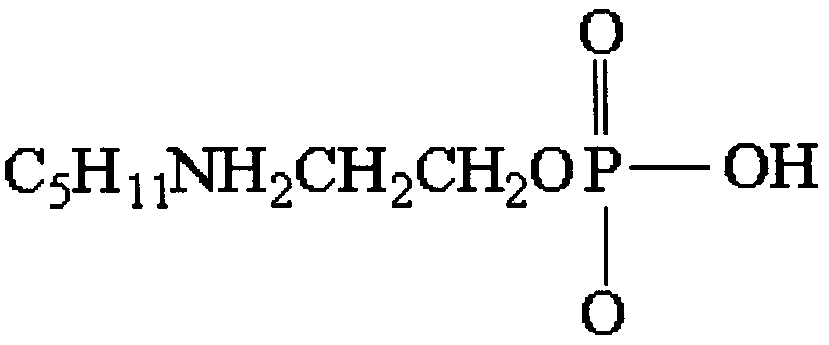

[0029] Synthesis of Synthesis Example 2 Phosphate Ester

[0030] Add 12mL of n-pentane bromide, 8ml of diethanolamine, 30ml of absolute ethanol and 4g of potassium silanolate to the three-necked flask, reflux and stir for 3 hours, cool, and filter to obtain the liquid; add 1.5ml of 85% phosphoric acid, 50ml of Acetone and 2g of phosphorus pentoxide were heated to 60°C, stirred and reacted for 2 hours, and the acetone was distilled off to obtain a light yellow liquid, which was phosphoric acid ester.

Synthetic example 3

[0031] Preparation of Synthetic Example 3 Composite Filler

[0032] Mix 300g of raw shell powder with 100g of aluminum phosphate and sinter at 500°C for 22min, then pulverize the sintered body and select powder with a particle size of 0.1-1.2μm; then carry out surface treatment on the powder, specifically put 200g of powder into Add 1800g of ethanol and 2.3g of hydroxyl-terminated polysiloxane powder into the container, stir for 45min, and finally dry to obtain the composite filler.

Synthetic example 4

[0033] The preparation of the alcohol ester of synthetic example 4 epoxy modification

[0034] In a nitrogen atmosphere, add 36g of bisphenol A epoxy resin, 100g of maleic anhydride and 240g of ethylene glycol into the reactor, react at 108°C for 50min, then add 6 drops of hydrochloric acid, and continue the reaction for 12min to obtain the epoxy resin Modified Alcohol Esters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com