Biomass boiler anticorrosive agent, and preparation and application thereof

A technology for biomass boilers and anti-corrosion agents, applied in fuel additives, petroleum industry, solid fuels, etc., can solve the problems of reduced anti-corrosion performance, accelerated corrosion, and enhanced oxidation of pipes, so as to reduce alkali metal corrosion and chlorine corrosion, structure The effect of stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

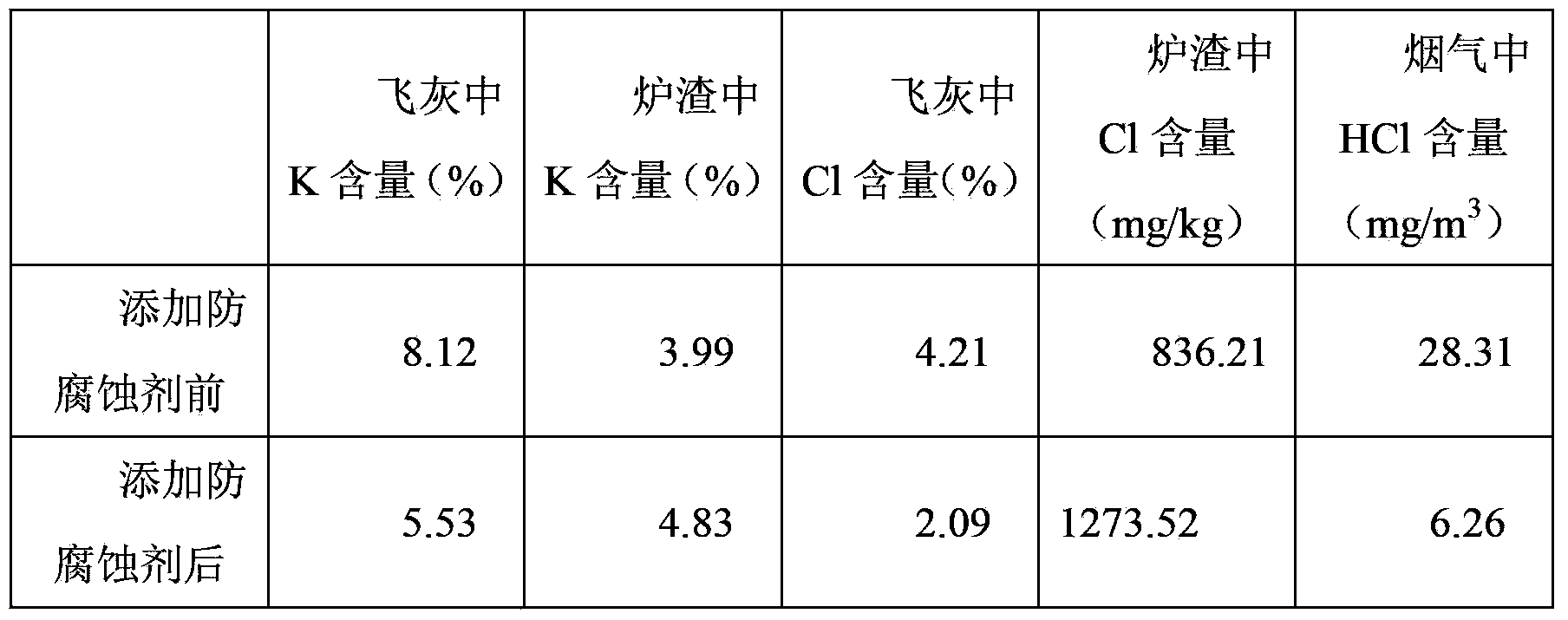

Embodiment 1

[0019] A kind of anticorrosion agent for biomass boiler, which is composed of coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 Composition, the mass of each component in the anti-corrosion agent is: 4kg coal ash (particle size 0.05-0.015mm), 2kg Al 2 (SO4) 3 , 3kg kaolin, 1kg CaSO 4 .

[0020] Above-mentioned biomass boiler corrosion inhibitor, its preparation method is as follows:

[0021] Step (1): Calcining 4kg of coal ash with a particle size of 0.05-0.15mm in a muffle furnace at 1000°C for 1 hour;

[0022] Step (2): Add 2kgAl 2 (SO4) 3 , 3kg kaolin, and 1kg CaSO 4 Grind to 0.05-0.1mm respectively, and add calcined coal ash for stirring, and after stirring evenly, press to form particles with rough threads on the outer surface.

[0023] Step (3): Bake the anticorrosion agent particles in a muffle furnace at 200°C for 0.5h to prepare the anticorrosion agent for biomass boilers. (of which coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 The mass percentage content is respec...

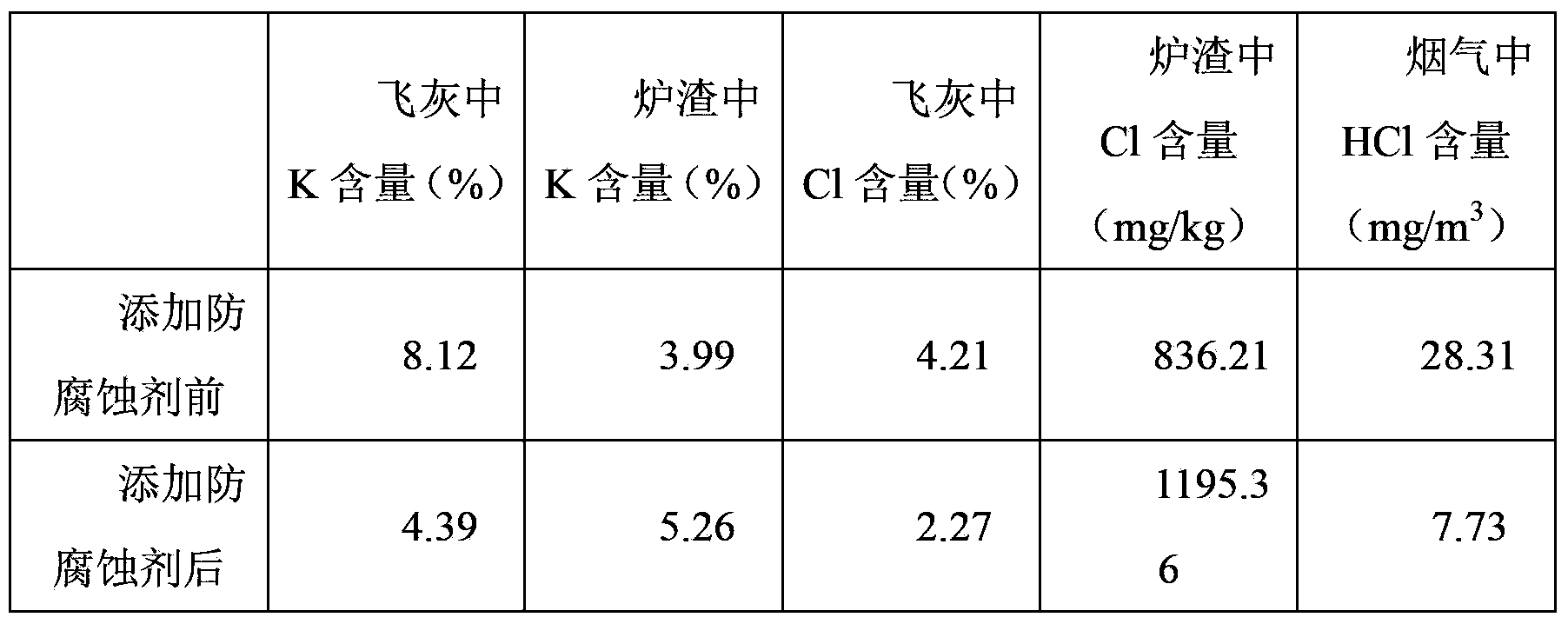

Embodiment 2

[0027] A kind of biomass boiler anticorrosion agent, this anticorrosion agent is made of coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 Composition, the mass of each component in the anti-corrosion agent is: 3kg coal ash (particle size 0.05-0.015mm), 1.5kgAl 2 (SO4) 3 , 4kg kaolin, 1.5kg CaSO 4 .

[0028] Above-mentioned biomass boiler corrosion inhibitor, its preparation method is as follows:

[0029] Step (1): Calcining 3kg of coal ash with a particle size of 0.05-0.15mm in a muffle furnace at 1050°C for 1.5h;

[0030] Step (2): Add 1.5kgAl 2 (SO4) 3 , 4kg kaolin, and 1.5kg CaSO 4 Grind to 0.05-0.1mm respectively, and add calcined coal ash for stirring, and after stirring evenly, press to form particles with rough threads on the outer surface.

[0031] Step (3): Bake the anticorrosion agent particles in a muffle furnace at 150° C. for 1 hour to prepare the anticorrosion agent for biomass boilers. (of which coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 The mass percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com