Method for synthesizing L-theanine through enzyme process

A technology of enzymatic synthesis and theanine, applied in the field of bioengineering, to achieve the effects of good thermal stability, good activity and stability, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Construction of ggt-pET20b(+) / E.coli BL21(DE3)

[0024] (1) According to the γ-glutamyl transpeptidase gene sequence of Bacillus subtilis 168 (NCBI Gene ID: 940001) on NCBI, the γ-glutamyl transpeptidase gene was obtained by chemical synthesis, and the gene was used as a template to design Primers P1, P2, P1: 5'–AT CCATGG ATAAAAAAACCGCCCAAAAGCTACGA–3’ (underlined is the enzyme cutting site NocI), P2: 5’–GGCG CTCGAG TTATTTACGTTTTAAATTAATGC-3' (the underline is the restriction site XhoI), the gene was amplified by PCR. The PCR system was 50 μl, and the PCR program was: pre-denaturation at 94°C for 4 minutes, followed by 30 cycles of "incubating at 98°C for 10 s, 55°C for 5 s, and 72°C for 120 s", and finally at 72°C for 10 min. The amplified target fragment was recovered and purified by gel and ligated with pMD18-T simple vector. After the ligation product is chemically transformed into Escherichia coli JM109, the transformation mixture is spread on an amp...

Embodiment 2

[0027] Embodiment 2: fermentation produces enzyme

[0028] (1) Fermentation culture

[0029] The genetically engineered bacteria ggt-pET20(b) / E.coli BL21(DE3) obtained in Example 1 was inoculated in LB / Amp liquid medium and then cultured at 37°C for 8-10 hours and then transferred to TB / Amp liquid medium containing 0.75% glycine, cultured at 37°C for 3 hours, then induced with 0.4mM / L IPTG (isopropylthio-β-D-galactoside), cooled to 25°C and incubated at a constant temperature for 40-48h to induce Enzymes. After the fermentation, the supernatant collected by centrifugation is the crude enzyme liquid.

[0030] (2) Enzyme activity assay

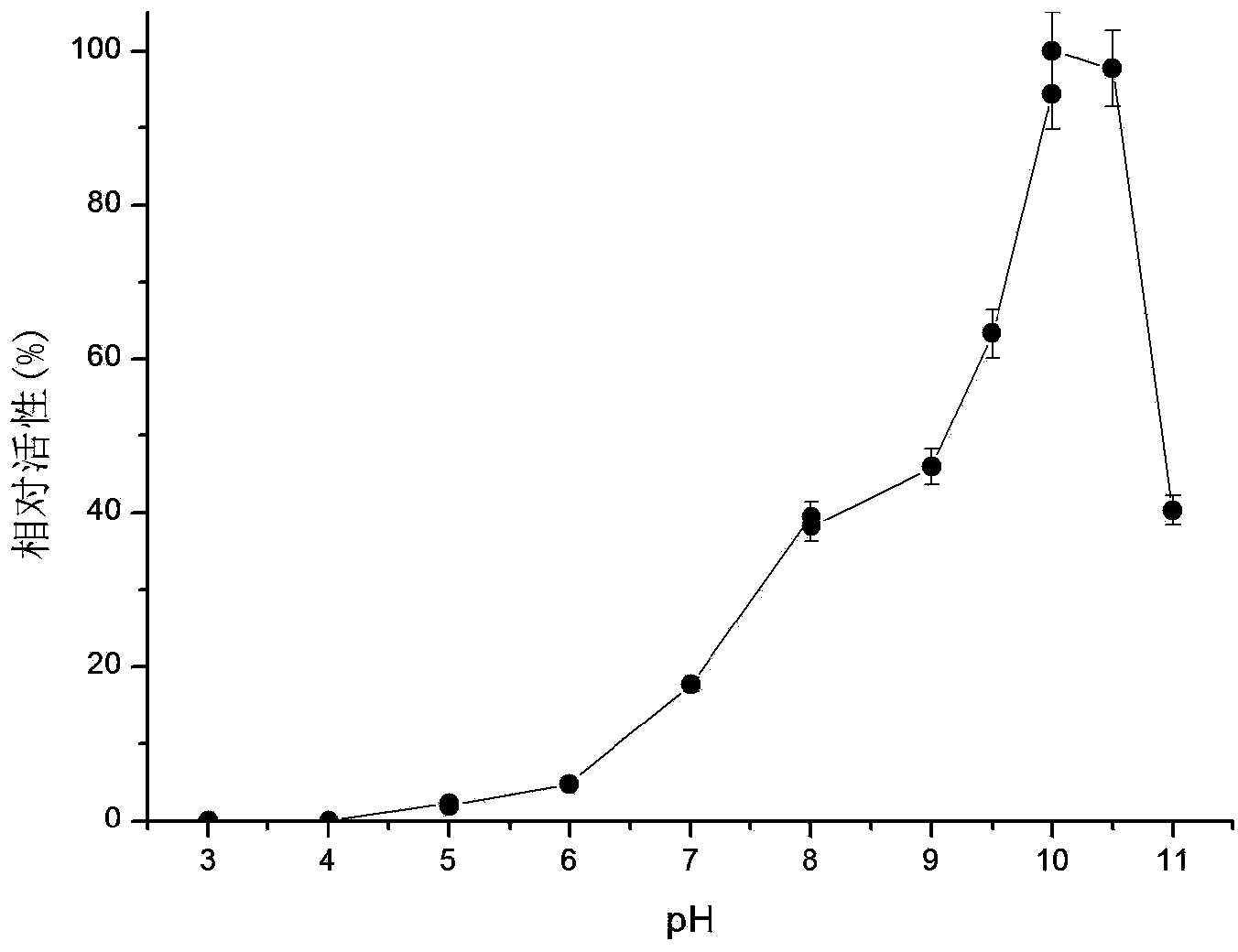

[0031] The color reaction was carried out with γ-glutamyl-p-nitroaniline (γ-GpNA) and glyceryl dipeptide (Gly-Gly) as substrates. The enzyme activity assay system is 1mL (contains a final concentration of 5mmol / L γ-glutamyl p-nitroanilide (γ-GpNA), 80mmol / L glyceryl dipeptide (Gly-Gly), 50mM borax-NaOH buffer, pH10) After adding 20 μL of appr...

Embodiment 3

[0033] Embodiment 3: the concentration of crude enzyme liquid

[0034] Slowly add thionine with a concentration of 60% relative to the mass fraction of the enzyme solution to the enzyme solution obtained in Example 2 while stirring, stir until the thionine is dissolved, and stand at 4°C for 8-10 hours to precipitate protein. The mixture was centrifuged (8000rpm, 10min) to collect the precipitate, and then reconstituted with a minimum volume of 50mM Tris-HCl buffer (pH8). According to the difference in reconstituted volume, the enzyme activity of the concentrated enzyme solution is 300-400U / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com