Device and method for calibrating optical fiber scanning light source wavelength based on gas absorption spectral lines

A technology of optical fiber scanning and gas absorption, which is applied in the field of optical fiber communication and sensing, can solve the problems of unfavorable calibration device miniaturization, modularization, unfavorable application system integration, and large volume of spectrometer, so as to achieve real-time calibration and precise positioning, strong The effect of scalability and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

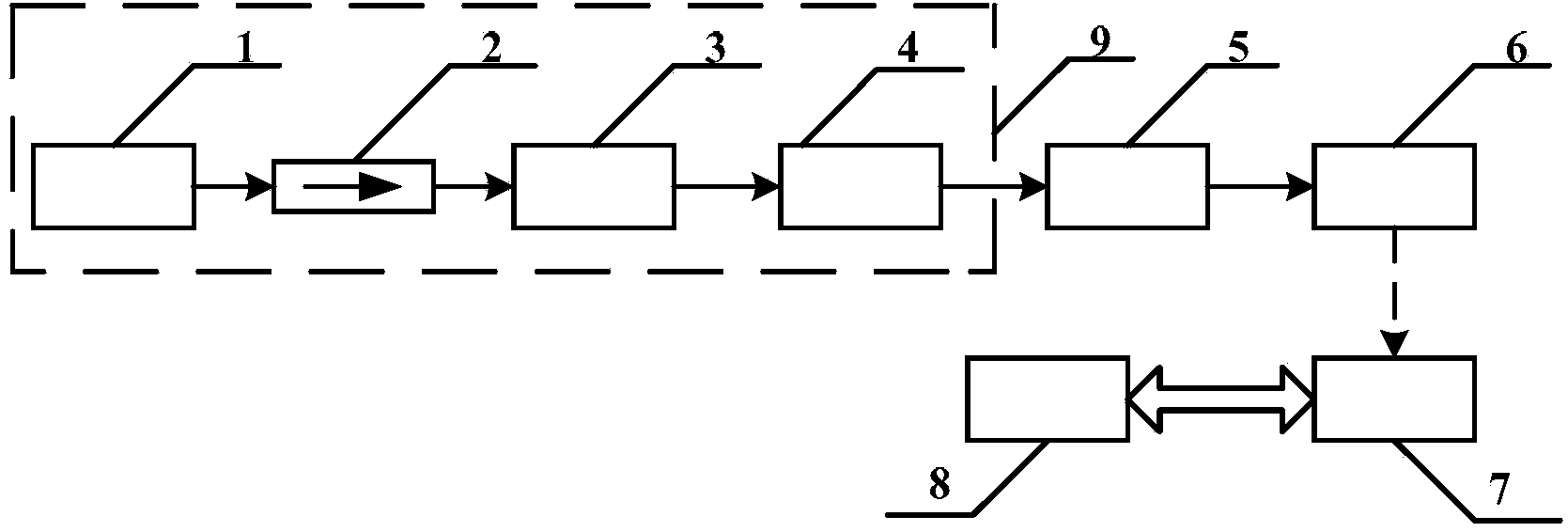

[0037] like figure 1 As shown, the optical fiber scanning light source wavelength calibration device based on gas absorption lines in the present invention includes a fiber scanning light source 9 , a gas chamber 5 , a detector 6 , a data acquisition card 7 and a computer 8 .

[0038] The optical fiber scanning light source 9 is composed of a broadband light source 1 , an isolator 2 , an adjustable attenuator 3 and a fiber optic Fab filter 4 arranged in sequence. Broadband light source 1, isolator 2, adjustable attenuator 3, fiber optic Fab filter 4, gas chamber 5, and detector 6 are connected in sequence through FC / APC single-mode fiber adapter, between detector 6 and data acquisition card 7 Connected by copper wires, the data acquisition card 7 and the computer 8 realize data communication through the USB interface.

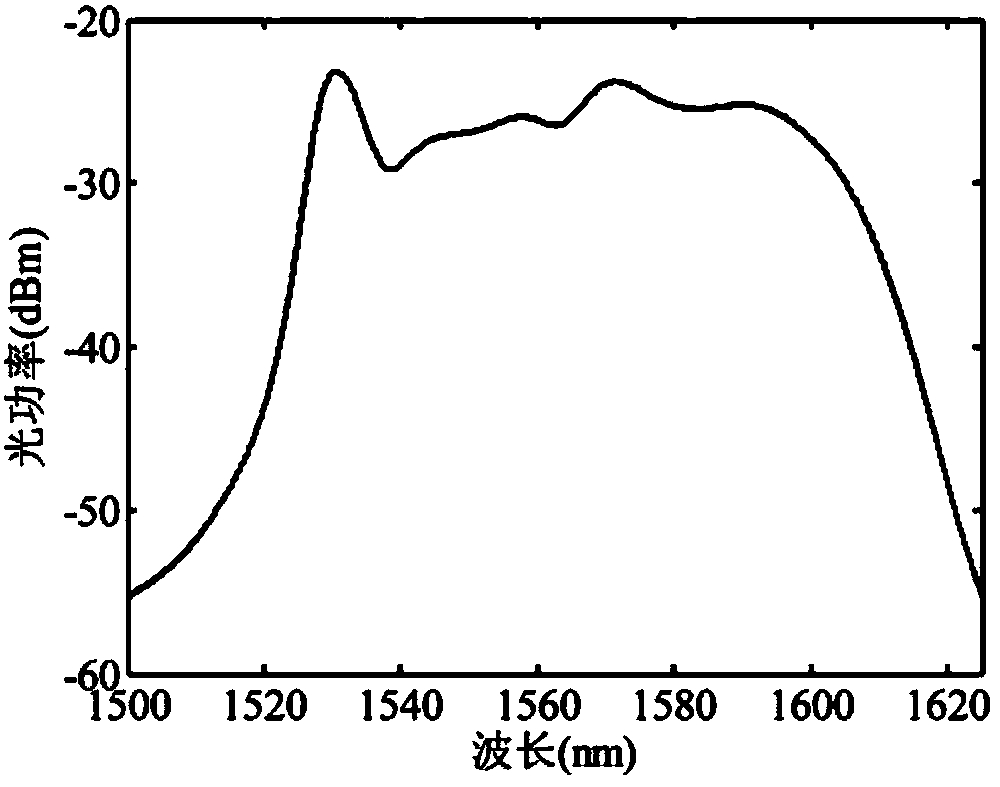

[0039] The light emitted by the broadband light source 1 passes through the isolator 2 and the adjustable attenuator 3 and then enters the continuous voltage-...

Embodiment 2

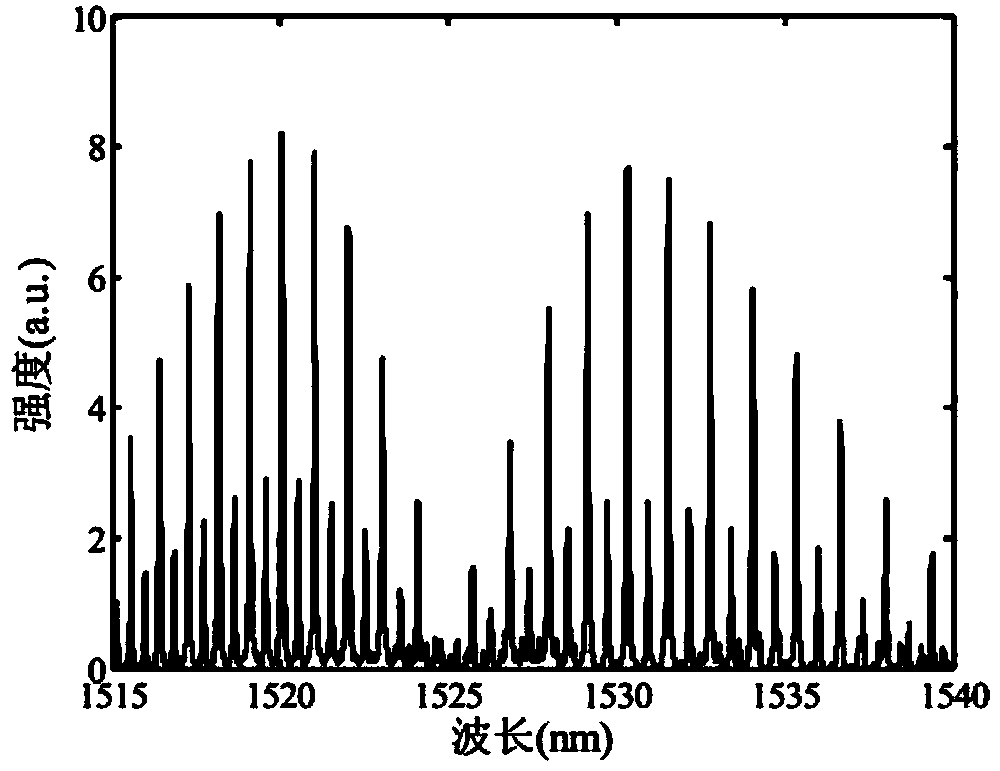

[0048] Acetylene is a gas that has a strong absorption of near-infrared light, and there are dozens of strong absorption lines between 1515nm and 1540nm, such as image 3 shown. Taking acetylene as an example, the wavelength calibration method of the optical fiber scanning light source 9 is described. In the actual calibration process, it is not necessary to collect all the absorption lines of the gas, and the local absorption spectrum can provide enough reference wavelengths for calibration. Figure 4 The gas absorption spectrum collected by the detector 6 is given when the driving voltage of the optical fiber scanning light source 9 varies between 6.6V and 9.6V, and the calibration gas is acetylene-nitrogen mixed gas, and the volume ratio of acetylene is 30%. The second-order derivative peak-seeking method is used for peak detection on the spectral curve. The driving voltage at the maximum value of the second-order derivative roughly corresponds to the central absorption wa...

Embodiment 3

[0052] The method described in the present invention is simple and easy to implement, the required calibration device is compact in structure, and is easy to integrate with other optical fiber sensing systems, so that the present invention can be used not only for offline calibration of the output wavelength of the scanning light source, but also for online real-time measurement of the optical wavelength. This embodiment 3 is an application expansion implementation of the present invention, Figure 8 An integration scheme of the fiber scanning light source calibration system and the fiber grating temperature measurement system is given. It includes a fiber scanning light source 9 composed of a broadband light source 1, an isolator 2, an adjustable attenuator 3 and a fiber Fap filter 4. The narrow linewidth scanning light output by the fiber Fap filter 4 is split into two by a 3dB coupler 10 A branch, 50% of the light enters the gas chamber 5 and the first photodetector 13 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com