Nutrient couscous suitable for steamed vegetable and instant rice, as well as production method and application of nutrient couscous

A technology of steamed powder and nutrition, applied in the fields of application, food preparation, food science, etc., can solve the problems of steamed powder with nutrition that have not yet been seen, and achieve the effect of extending the agricultural industry chain, stable quality, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

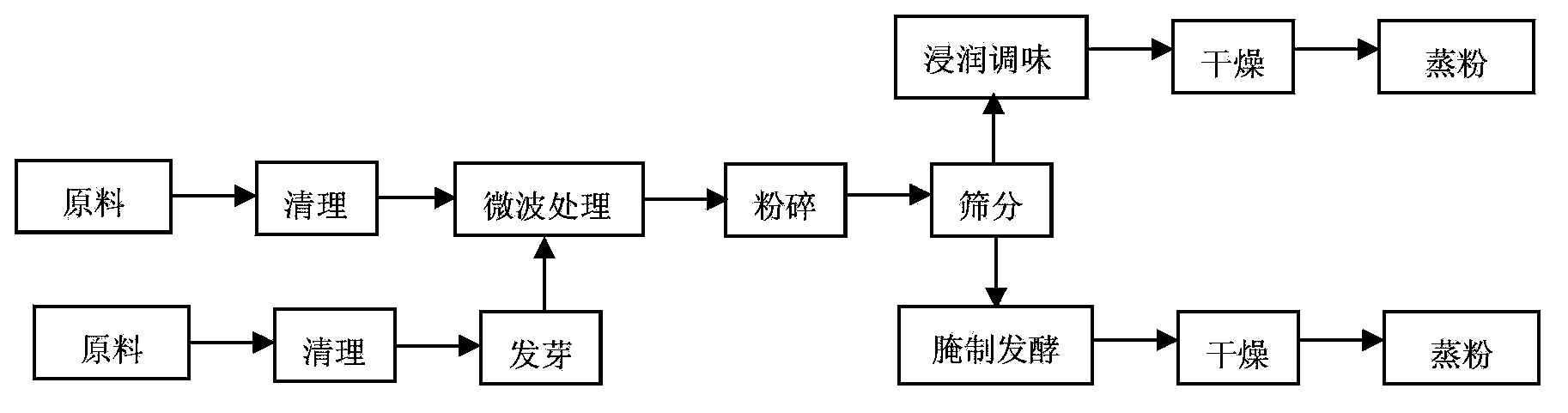

Method used

Image

Examples

Embodiment 1

[0075] Example 1: Production of a chopped pepper-flavored nutritional steamed powder (germination process + fermentation process)

[0076] Step 1: Rinse 70kg of brown rice with clean water for 2 to 3 times, take out and drain the water, and obtain material 1;

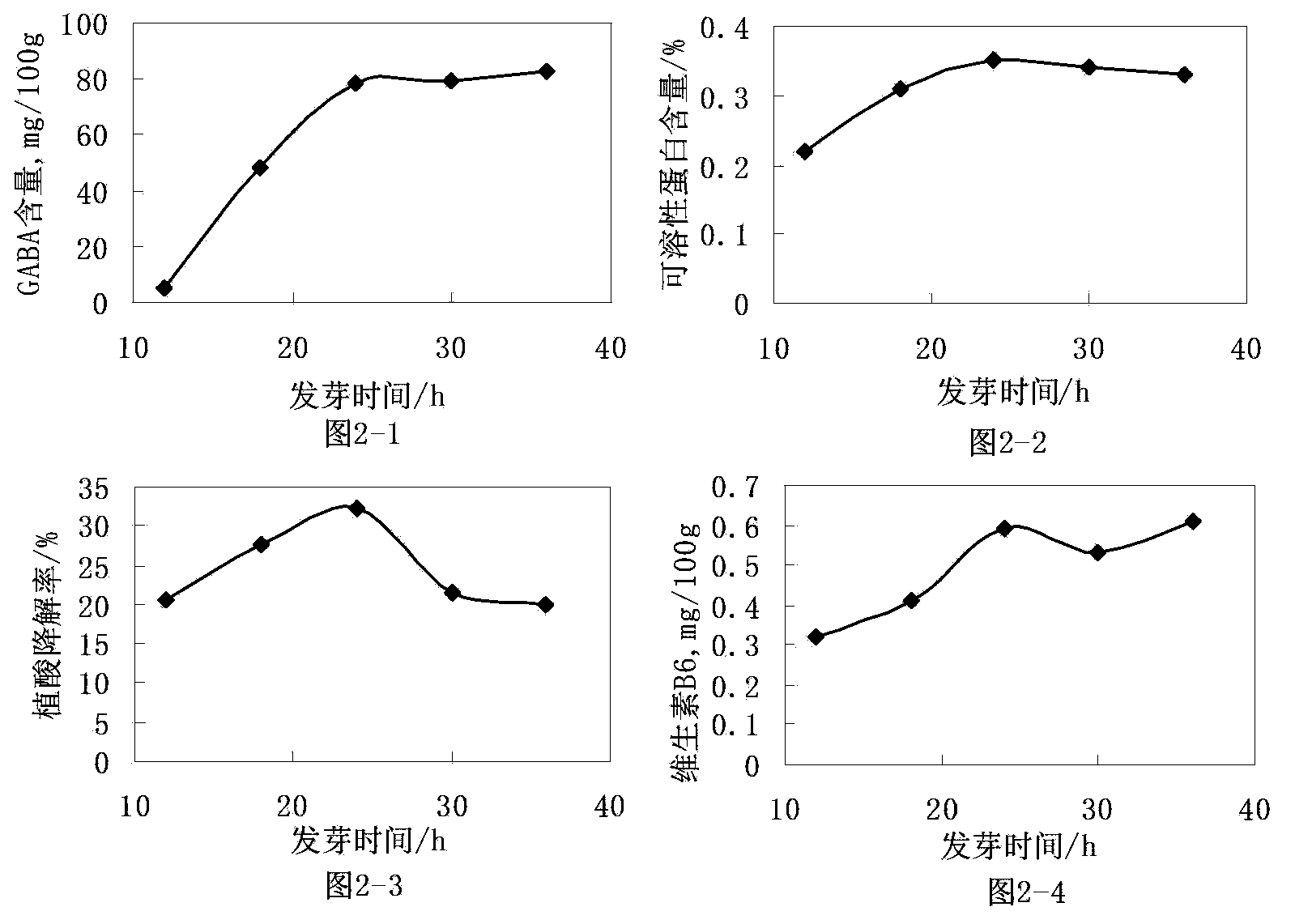

[0077] Step 2: Put the above material 1 (brown rice) in the nutrient soaking solution (formula: calcium lactate 0.3~0.8mmol / L, L-sodium glutamate 1.5~4mmol / L, gibberellin 0.1~0.2mg / L, use clean tap water to 1L), soaking temperature is 25~37°C, soaking time is 10h, after draining, place it at 30°C, and cultivate it under the condition of 70%~98% relative humidity to make it germinate. The cultivation time for germination is 36h, until the bud length is about 0.5~1.1mm, take it out and wash it with water, and then dry it with 1.5w / g microwave for 20min to obtain material 2;

[0078] Step 3: Put the above-mentioned material 2 in a pulverizer and crush it to obtain a material between 20 and 60 meshes. Take 50 kg for use as...

Embodiment 2

[0088] Example 2: Production of a pickled pepper-flavored nutritional steamed powder (germination process)

[0089] Step 1: Take 15kg of mung beans and 15kg of red beans, which are raw materials of miscellaneous grains, wash them, soak them in clean water at 25-30°C for 8 hours, drain them, and culture them at 20-30°C for 36 hours to germinate them (until the bud length is 0.5-1.1mm). 1.5w / g microwave drying for 20min to obtain material 1;

[0090] Step 2: Take 30kg of broken rice and rinse it with water for 2~3 times, take out and drain the water, and dry it with 1.5w / g microwave for 20min to obtain material 2;

[0091] Step 3: Put material 1 and material 2 in a pulverizer and pulverize to obtain materials between 20 and 60 meshes, take 25 kg each, mix them for later use, and obtain material 3;

[0092] Step 4: Weigh 2.5kg of table salt, 1kg of white sugar, 15kg of pickled pepper (commercially purchased, with a salt content of 6.5%, minced), 1.5kg of red yeast rice (commerci...

Embodiment 3

[0094] Example 3: Production of a pickled pepper-flavored nutritional steamed powder (fermentation process)

[0095] Step 1: Rinse 70 kg of broken rice raw material with water for 2 to 3 times, take out and drain the water, and obtain material 1;

[0096] Step 2: Dry material 1 with 1.5w / g microwave for 20 minutes to obtain material 2;

[0097] Step 3: Put the material 2 in a pulverizer and pulverize it to obtain a material between 20 and 60 meshes, and take 50 kg of the material 3 as a spare.

[0098] Step 4: Weigh minced garlic 1.25kg, minced ginger 1.25kg, salt 2.5kg, sugar 1.5kg, pickled pepper (commercially purchased, salt content 6.5%, minced) 10kg, mix well to obtain auxiliary materials, 50kg spare material 3 Mix and mix well with auxiliary materials to obtain material 4;

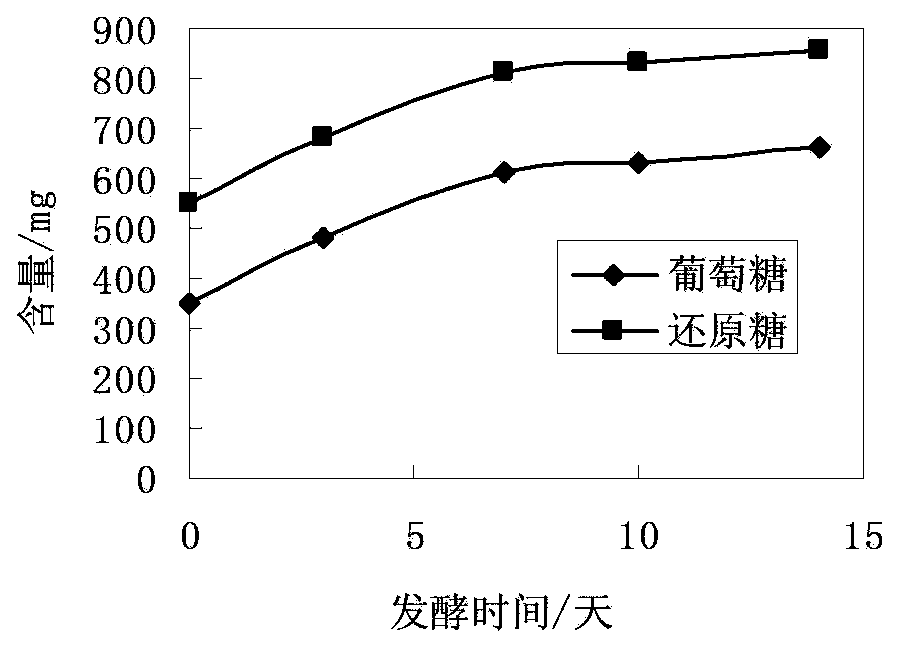

[0099] Step 5: Put the material 4 obtained in step 3 in a container, keep away from light, seal and ferment for 7 days (at room temperature), and obtain material 5;

[0100] Step 6: The material 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com