Polyurethane elastic body material for silk-screen printing squeegee and preparation method thereof

A polyurethane elastomer and screen printing technology, applied in the field of polyurethane elastomer and its preparation, can solve the problems of long demoulding time, high viscosity of prepolymer, difficult operation process, etc., and achieve excellent solvent resistance and good resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of polyester polyol PSE1-1: 2259g of succinic acid, 530g of terephthalic acid, 1270g of ethylene glycol, and 542g of diethylene glycol are added to a reactor with a condenser and a fractionating tower, and heated under nitrogen protection Stir, gradually raise the temperature to 220-230°C until no reaction-generated water distills out under normal pressure, carry out decompression and compression polymerization, and slowly increase the vacuum degree to -0.095MPa, heat preservation reaction until the acid value is qualified, then cool down to 100°C to exit material. The hydroxyl value of the prepared polyester polyol is 74.0 mgKOH / g, and the acid value is 0.5 mgKOH / g.

[0034] Preparation of polyester polyol PSE1-2: 2400 g of succinic acid, 422 g of phthalic acid, 1390 g of ethylene glycol, and 388 g of neopentyl glycol. The hydroxyl value of the prepared polyester polyol is 75.0 mgKOH / g, and the acid value is 0.8 mgKOH / g. Other operations are the same as P...

Embodiment 1

[0036] Preparation of component A: 1-1100 parts of polyester polyol PSE, 110 parts of MDI, react at 80°C for 1.5h, vacuumize and defoam, cool down to 50°C and discharge to obtain component A.

[0037] Preparation of component B: after dehydration of polyester polyol PSE2, component B is obtained.

[0038] Preparation of component C: Mix 100 parts of 1,4-butanediol and 8.3 parts of Dabco33-LV / T-9 (mass ratio 6 / 1) to obtain component C.

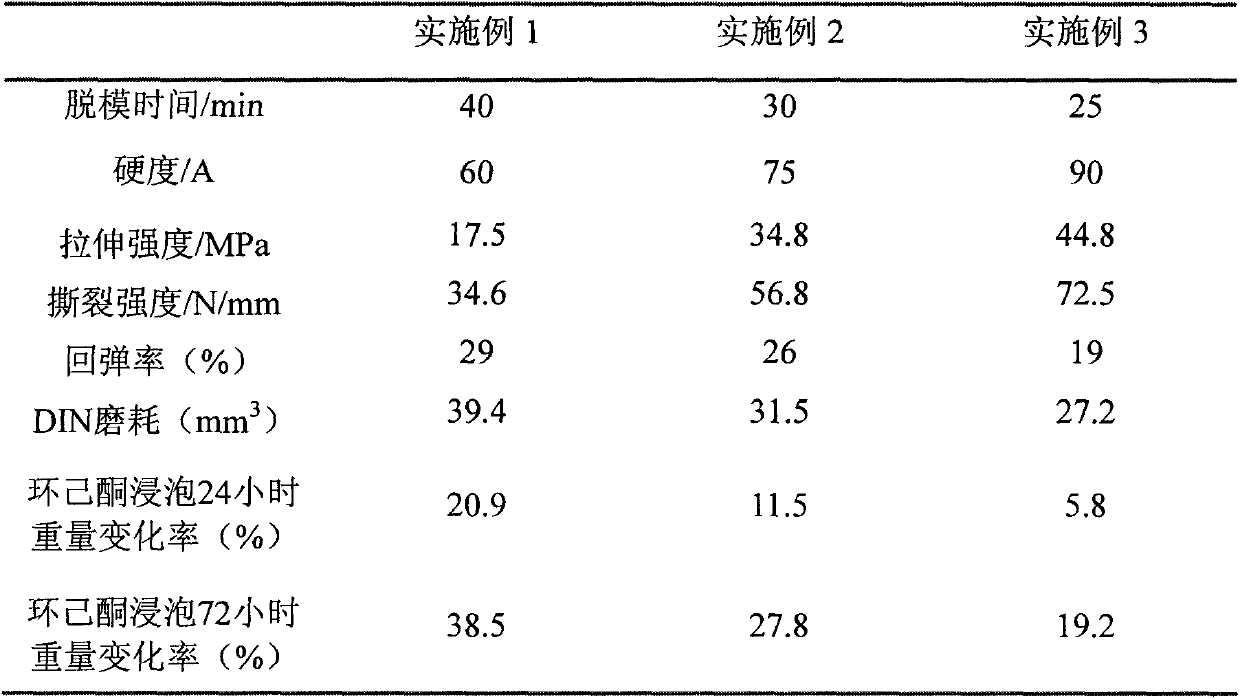

[0039] Control the temperature of component A at 80-90°C, the temperature of components B and C within the range of 40-50°C, adjust the proportion of components A, B, and C to 100 / 160 / 10.5, and mix the three components thoroughly , injected into a 4mm mold for molding, the mold temperature is 100°C, demolded in 40 minutes, vulcanized at 100°C for 24 hours, and tested for performance after 7 days at room temperature. Product properties are shown in Table 2.

Embodiment 2

[0041] Preparation of component A: 1-2100 parts of polyester polyol PSE, 120 parts of MDI, react at 80°C for 1.5h, defoam in vacuum, cool down to 50°C and discharge to obtain component A.

[0042] Preparation of component B: after dehydration of polyester polyol PSE2, component B is obtained.

[0043] Preparation of component C: Mix 100 parts of 1,4-butanediol and 5 parts of Dabco33-LV / T-9 (mass ratio 6 / 1) to obtain component C.

[0044]Control the temperature of component A at 80-90°C, the temperature of components B and C within the range of 40-50°C, adjust the proportion of components A, B, and C to 100 / 115 / 12, and mix the three components thoroughly , injected into a 4mm mold for molding, the mold temperature is 100°C, demolded in 40 minutes, vulcanized at 100°C for 24 hours, and tested for performance after 7 days at room temperature. Product properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com