Fatty amine polyoxyethylene ether carboxylate and preparation method thereof

A technology of aliphatic amine polyoxyethylene ether carboxylate and fatty amine polyoxyethylene ether, which is applied in the field of fatty amine polyoxyethylene ether carboxylate and its preparation, can solve the problem of poor thermal stability of foaming agents and cannot meet the needs of foam flooding and other issues to achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

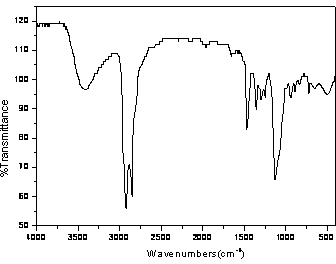

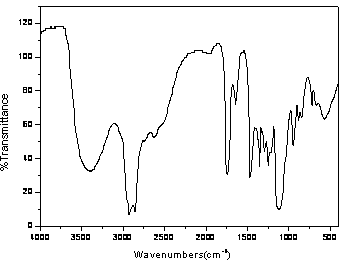

Image

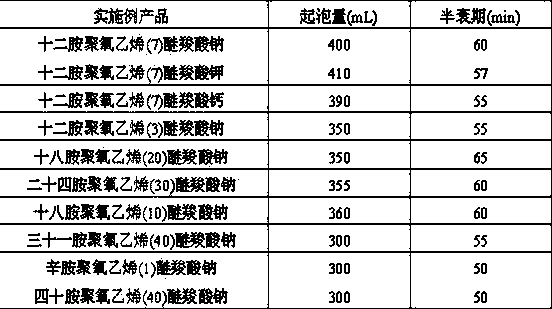

Examples

Embodiment 1

[0025] Synthesis of Dodecylamine Polyoxyethylene (7) Ether Carboxylate

[0026] (1) Add 93g (0.5 moles) of dodecylamine and 1% potassium hydroxide catalyst of amine weight to the reactor equipped with condensing device, stirring device and gas disperser, heat the system temperature to 80-90°C, and turn on Vacuum system, dehydrated under high vacuum for 1 hour, then purged with nitrogen for 3 to 4 times to remove the air in the system, then adjusted the reaction temperature of the system to 120°C and slowly introduced 154g of ethylene oxide, controlling the pressure from 0.1 to 1.0MPa, temperature 120-180°C, carry out alkoxylation reaction; after the reaction, remove unreacted ethylene oxide, neutralize after cooling, decolorize, filter, and dehydrate to obtain dodecylamine polyoxyethylene (7) ether.

[0027] (2) 240 g (0.5 moles) of dodecylamine polyoxyethylene (7) ether synthesized in step (1) was started to heat up the stirring device to 70° C. and slowly added dropwise an ...

Embodiment 2

[0031] Synthesis of Dodecylamine Polyoxyethylene (3) Ether Carboxylate

[0032] (1) Add 93g (0.5 moles) of dodecylamine and 1% potassium hydroxide catalyst of amine weight to the reactor equipped with condensing device, stirring device and gas disperser, heat the system temperature to 80-90°C, and turn on Vacuum system, dehydrated under high vacuum for 1 hour, then purged with nitrogen for 3 to 4 times to remove the air in the system, then adjusted the reaction temperature of the system to 120°C and slowly introduced 70g of ethylene oxide, controlling the pressure from 0.1 to 1.0MPa, temperature 120-180°C, carry out alkoxylation reaction; after the reaction, remove unreacted ethylene oxide, neutralize after cooling, decolorize, filter, and dehydrate to obtain dodecylamine polyoxyethylene (3) ether.

[0033](2) 160 g (0.5 moles) of dodecylamine polyoxyethylene (3) ether synthesized in step (1) was started to heat up the stirring device to 60° C. and slowly added dropwise an aq...

Embodiment 3

[0036] Synthesis of octadecylamine polyoxyethylene (20) ether carboxylate

[0037] (1) Add 135g (0.5 moles) of octadecylamine and potassium hydroxide catalyst with 1% weight of amine to the reactor equipped with condensing device, stirring device and gas disperser, heat the system temperature to 80-90°C, and turn on Vacuum system, dehydrated under high vacuum for 1 hour, then purged with nitrogen for 3 to 4 times to remove the air in the system, then adjusted the reaction temperature of the system to 120°C and slowly introduced 440g of ethylene oxide, controlling the pressure from 0.1 to 1.0MPa, temperature 120-180°C, carry out alkoxylation reaction; after the reaction, remove unreacted ethylene oxide, neutralize after cooling, decolorize, filter, and dehydrate to obtain octadecylamine polyoxyethylene (20) ether.

[0038] (2) 570 g (0.5 mole) of stearylamine polyoxyethylene (20) ether synthesized in step (1) was started to heat up the stirring device to 80° C. and slowly adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com