Polyether type polyurethane prepolymer containing long lateral-chain organosilicon, and preparation method and application thereof

A technology of polyether polyurethane and silicone, which is applied in the field of chemistry and chemical engineering, can solve the problems of difficult control and fast reaction speed, and achieve the effects of moderate reaction speed, improved surface properties and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

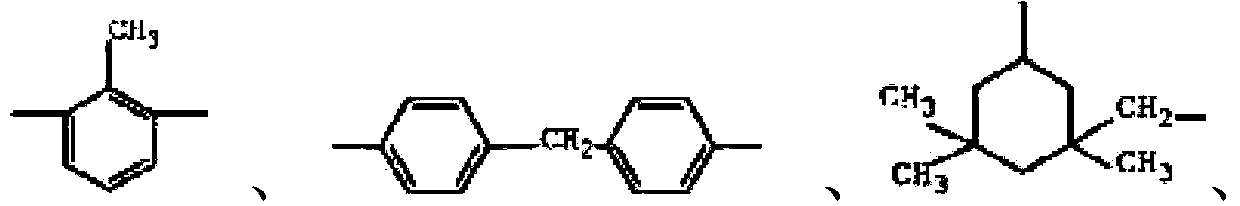

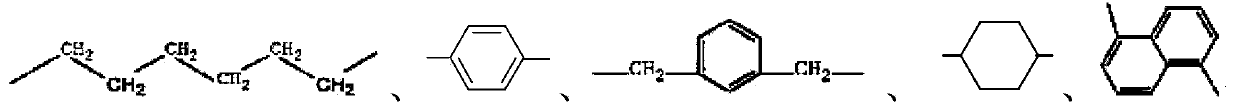

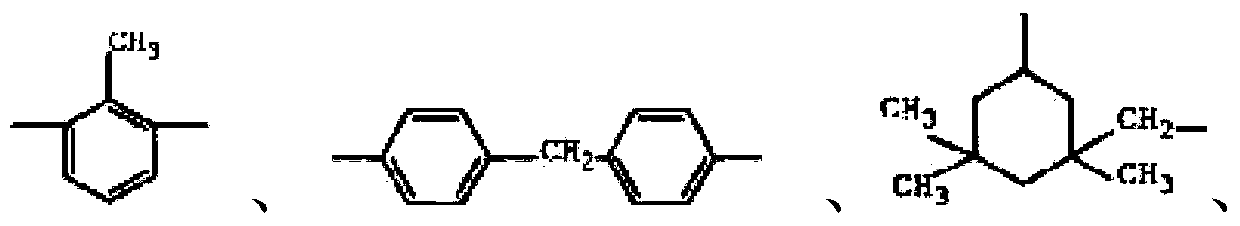

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the polyether polyurethane prepolymer containing long side chain organosilicon of the present invention comprises the following steps:

[0039] (1) Preparation of long-chain single-ended hydroxyl polydimethylsiloxane

[0040] In a 500ml three-necked bottle equipped with a mechanical electric stirrer and a thermometer, add 200g α, ω-dihydroxy polydimethylsiloxane (average molecular weight 15000), 100ml toluene, mix and stir for 20 minutes, and control the reaction temperature with ice water In the range of -5°C to 5°C, a toluene solution containing 1.5 g of trimethyl-chlorosilane was added dropwise through a dropping funnel under stirring conditions. After the reaction is complete, add 1.5 g of triethylamine to neutralize the hydrogen chloride produced, wash with distilled water until the solution is neutral, then remove toluene and water by rotary evaporation at 70°C, and dry the product under vacuum at 110°C for 3 hours to remove water to obta...

Embodiment 2

[0053] The preparation method of the polyether polyurethane prepolymer containing long side chain organosilicon of the present invention comprises the following steps:

[0054] (1) Preparation of long-chain single-ended hydroxyl polydimethylsiloxane

[0055] In a 1500ml three-necked bottle equipped with a mechanical electric stirrer and a thermometer, add 800gα,ω-dihydroxypolydimethylsiloxane (average molecular weight: 50000), 400ml toluene, mix and stir for 60 minutes, and control the reaction temperature with ice water In the range of -5°C to 5°C, a toluene solution containing 1.8 g of trimethylchlorosilane was added dropwise through a dropping funnel under stirring conditions. After the reaction is complete, add 1.8 g of triethylamine to neutralize the hydrogen chloride produced, wash with distilled water until the solution is neutral, then remove toluene and water by rotary evaporation at 80°C, and vacuum dry the product at 130°C for 2 hours to remove water to obtain a lon...

Embodiment 3

[0068] The preparation method of the polyether polyurethane prepolymer containing long side chain organosilicon of the present invention comprises the following steps:

[0069] (1) Preparation of long-chain single-ended hydroxyl polydimethylsiloxane

[0070] In a 1500ml three-necked bottle equipped with a mechanical electric stirrer and a thermometer, add 800g of α, ω-dihydroxy polydimethylsiloxane (average molecular weight: 100,000), 400ml of toluene, mix and stir for 60 minutes, and control the reaction temperature with ice water In the range of -5°C to 5°C, a toluene solution containing 0.9 g of trimethylmonochlorosilane was added dropwise through a dropping funnel under stirring conditions. After the reaction is complete, add 0.9 g of triethylamine to neutralize the hydrogen chloride produced, wash with distilled water until the solution is neutral, then remove toluene and water by rotary evaporation at 50°C, and vacuum-dry the product at 100°C for 3 hours to remove water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com