Exhaust gas recycling system for garbage brick factory

A technology of waste gas circulation and garbage production, applied in the field of environmental protection, can solve problems such as unpleasant odor, environmental and human hazards, and short service life, and achieve the effects of accelerating cooling efficiency, avoiding dust pollution, and accelerating drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

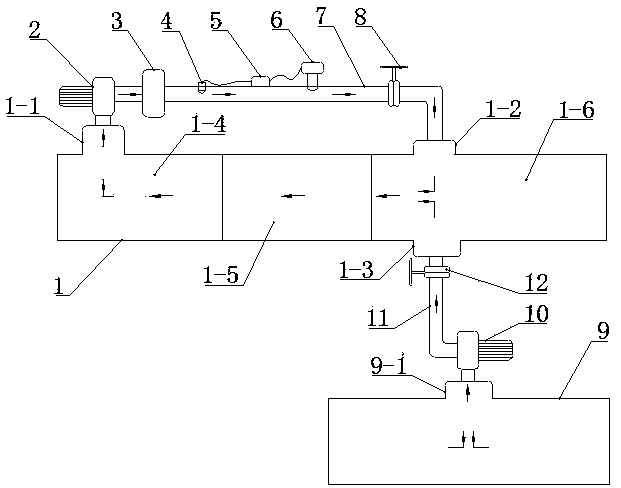

[0015] like figure 1 As shown, a waste gas recycling system in a garbage brick factory includes a kiln body 1 and a closed garbage billet workshop 9. The kiln body 1 is divided into a brick drying section 1-4, a furnace section 1-5 and Brick forming cooling section 1-6 has three sections, the brick drying section 1-4 is provided with an exhaust port 1-1, and the brick forming cooling section 1-6 is provided with an air inlet 1-2 and an air inlet Two 1-3, the closed garbage billet workshop 9 is provided with an exhaust port two 1-3; the exhaust port one 1-1 is equipped with a fan one 2, and the fan one 2 is equipped with a connecting fan one 2 and The air duct-7 of the brick cooling section 1-6, the air inlet of the fan-2 communicates with the exhaust port-1-2, and one end of the air duct-7 communicates with the air outlet of the fan-2, and the air duct-7 The other end is communicated with the air inlet one 1-2, and the air duct one 7 is provided with a dust collector 3, an ox...

Embodiment 2

[0019] like figure 1 As shown, a waste gas recycling system in a garbage brick factory includes a kiln body 1 and a closed garbage billet workshop 9. The kiln body 1 is divided into a brick drying section 1-4, a furnace section 1-5 and Brick forming cooling section 1-6 has three sections, the brick drying section 1-4 is provided with an exhaust port 1-1, and the brick forming cooling section 1-6 is provided with an air inlet 1-2 and an air inlet Two 1-3, the closed garbage billet workshop 9 is provided with an exhaust port two 1-3; the exhaust port one 1-1 is equipped with a fan one 2, and the fan one 2 is equipped with a connecting fan one 2 and The air duct-7 of the brick cooling section 1-6, the air inlet of the fan-2 is communicated with the exhaust port-1-2, and one end of the air duct-7 is communicated with the air outlet of the fan-2, and the air duct-7 The other end is communicated with the air inlet one 1-2, and the ventilation pipe one 7 is provided with a dust coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com