Lithium ion battery composite anode material and preparation thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of high capacity, good stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

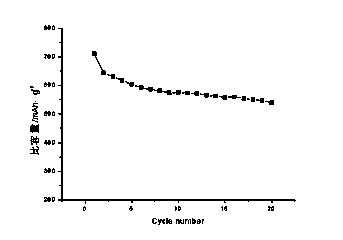

Examples

Embodiment 1

[0022] Example 1 Mix nano-silicon with a particle size of 50nm, lithium hydride of 25nm and carbon nanotubes of 100nm at a ratio of 40%, 10%, and 50% and ball mill at 500r / min for 48 hours, and add 0.5% of silane coupling agent. The content of the mixed matrix powder is 10% % phenolic resin alcohol solution after stirring, volatilize the solvent, conduct heat treatment at 300°C for 1 hour, pulverize, sieve and add to the phenolic resin alcohol solution containing 0.5% silane coupling agent whose content is 5% of the mass of the mixed matrix powder and stir The solvent was evaporated, dried at 80°C, and then heated at 5°C / min to 600°C for 2 hours, then naturally cooled to room temperature to obtain a lithium-ion battery composite negative electrode material.

Embodiment 2

[0023] Example 2 The particle size is 70nm nano-silicon, 25nm lithium hydride and 100nm carbon nanotubes are mixed according to the ratio of 65%, 15%, 20% and ball milled at 1000r / min for 24h, and the content of 0.6% carboxymethyl cellulose is added to the mixed matrix powder mass 20 % of kerosene asphalt carbon disulfide solution after stirring, volatilize the solvent, heat treatment at 350°C for 1 hour, pulverize, and add to the carbon disulfide solution of kerosene asphalt containing 0.6% carboxymethyl cellulose with a content of 5% of the mass of the mixed matrix powder after sieving After stirring, the solvent was evaporated, dried at 80°C, heated at 5°C / min to 700°C for 2 hours, and cooled naturally to room temperature to obtain a lithium-ion battery composite negative electrode material.

Embodiment 3

[0024] Example 3 Mix nano-silicon with a particle size of 60nm, 25nm lithium hydride and 500nm natural flake graphite at a ratio of 60%, 20%, and 20% and ball mill at 2000r / min for 6h, and add 0.7% titanate coupling agent to the mass of the mixed matrix powder Stir in 5% polyvinyl chloride alcohol solution to volatilize the solvent, heat-treat at 385°C for 1 hour, pulverize, and add to polyvinyl chloride containing 0.7% titanate coupling agent and the content is 5% of the mixed matrix powder mass after sieving After stirring in the alcohol solution, the solvent was evaporated, dried at 80°C and then heated to 800°C at 5°C / min for 2 hours, and cooled naturally to room temperature to obtain a lithium-ion battery composite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com