Soybean protein isolate with low phytic acid and preparation method thereof

A technology of soybean protein isolate and soybean protein concentrate, applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve the problems of poor color, limited functionality, poor sensory properties, etc., and achieve good solubility and sensory Properties, light taste, low sugar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

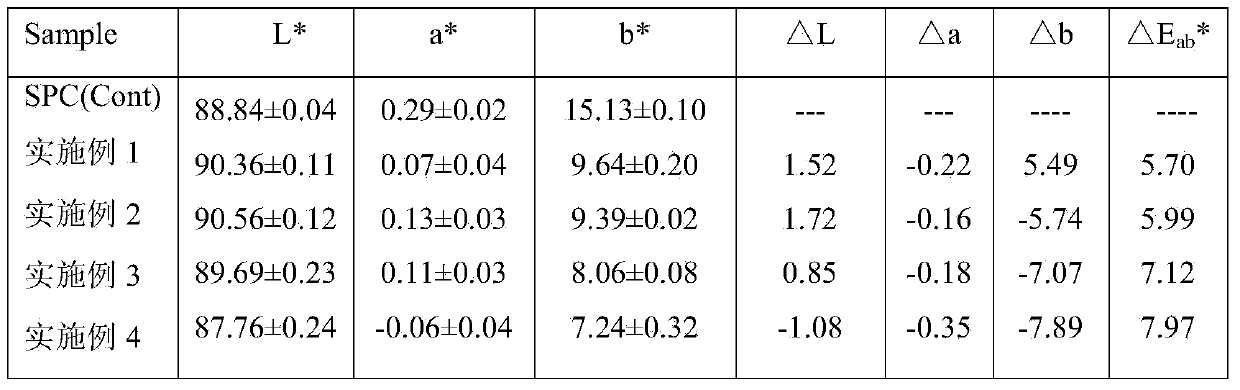

Examples

Embodiment 1

[0032] A preparation method of low phytic acid soybean protein isolate, comprising the steps of:

[0033] Step 1: 200g of SPC (protein content 63.57%, nitrogen solubility index 8.77%, phytic acid content 2.59%, isoflavone content 0.15mg / g) was dispersed in 3000mL aqueous solution with a solid-liquid ratio of 1:15w / v, and the pH was adjusted to 9.0 , stirred at room temperature for 2h;

[0034] Step 2: The dispersion liquid in Step 1 is processed in a colloid mill for 10 minutes at an angular velocity of 1000 rpm, with a grinding hole of 0.15 mm;

[0035] Step 3: The treatment liquid in step 2 is placed in a jet cooker, and jet cooks at 140° C. for 90 seconds;

[0036] Step 4: In step 3, the protein slurry was adjusted to pH 4.5 and acid-precipitated for 30 minutes, and then the centrifuged protein precipitate was redissolved in 7 times the volume of deionized water, and the soluble components were adjusted to neutral pH, then dialyzed in deionized water and spray-dried avail...

Embodiment 2

[0041] A preparation method of low phytic acid soybean protein isolate, comprising the steps of:

[0042] Step 1: 200g of SPC (protein content 63.57%, nitrogen solubility index 8.77%, phytic acid content 2.59%, isoflavone content 0.15mg / g) was dispersed in 3000mL aqueous solution with a solid-liquid ratio of 1:15w / v, and the pH was adjusted to 9.0 , stirred at room temperature for 2h;

[0043] Step 2: The dispersion in Step 1 is treated with an angular velocity of 1000 rpm and a colloid mill with a grinding hole of 0.15 mm for 10 minutes;

[0044] Step 3: The treatment solution in Step 2 is subjected to jet cooking treatment at 140° C. for 90 s;

[0045] Step 4: After adjusting the pH of the dispersion in step 3 to 5.0, add 20g of phytase (20,000 U / g) and 10mg of acid phosphatase (3.0-10U / mg), stir at 50°C for 2 hours, and hydrolyze phytic acid ( salt) to inactivate the enzyme;

[0046] Step 5: In step 4, the protein slurry was adjusted to pH 4.5 and acid-precipitated for 3...

Embodiment 3

[0051] A preparation method of low phytic acid soybean protein isolate, comprising the steps of:

[0052] Step 1: Disperse 200g of SPC (protein content 63.57%, nitrogen solubility index 8.77%, phytic acid content 2.59%, isoflavone content 0.15mg / g) in 3000mL aqueous solution at a solid-liquid ratio of 1:15w / v, adjust pH to 9.0, and keep at room temperature Stir for 2h;

[0053] Step 2: The dispersion in Step 1 is treated with an angular velocity of 1000 rpm and a colloid mill with a grinding hole of 0.15 mm for 10 minutes;

[0054] Step 3: The treatment solution in Step 2 is subjected to jet cooking treatment at 140° C. for 90 s;

[0055] Step 4: After adjusting the pH of the dispersion in step 3 to 5.0, add 20g of phytase (20,000 U / g) and 10mg of acid phosphatase (3.0-10U / mg), stir at 50°C for 2 hours, and hydrolyze phytic acid (salt ) after inactivating the enzyme;

[0056] Step 5: In step 4, the dispersion liquid is roughly filtered with 4 layers of gauze and then filter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap