Three-way catalyst used for automobile emission purification and preparation method thereof

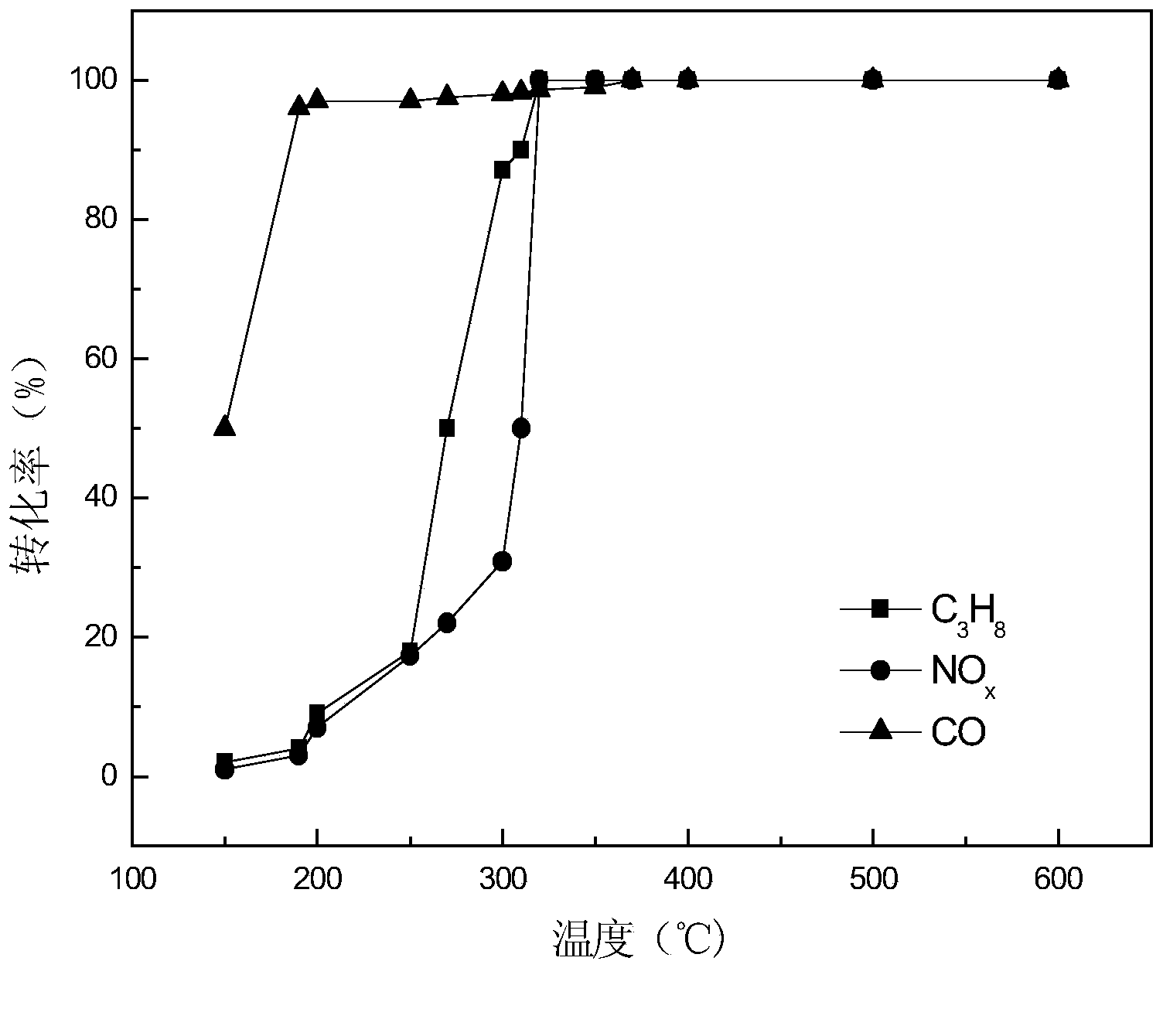

A three-way catalyst, automobile exhaust technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Market application limitations, high light-off temperature problems, to achieve the effect of promoting three-effect performance, active redox performance, and purifying automobile exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Based on the mass of the cordierite carrier, the mass percentage of the co-catalyst coating is 12%, and the mass percentage of the catalytically active component is 3.3%. The mass ratio of noble metal to transition metal in the catalytic active component is 1:10, the molar ratio of noble metal Rh / Pd is 1:10, and the molar ratio of transition metal Co / Ni is 1:2; the γ-Al in the cocatalyst coating 2 o 3 With rare earth composite oxide (Ce-Zr-M-O x ) with a mass ratio of 1:0.75, wherein the metal M in the rare earth composite oxide is Pr, and the element molar ratio of Ce / Zr / M is 1:0.33:0.01.

[0025] (1) Pretreatment of the carrier

[0026] Put the cordierite honeycomb ceramic carrier into HNO with a mass percentage of 8% 3 Perform surface modification treatment in the solution, place it on a resistance furnace and heat it to boiling, wash the surface layer and residual acid solution in the holes with water after cooling, and put it in an oven to dry for later use;

...

Embodiment 2

[0036] Based on the mass of the cordierite carrier, the mass percentage of the co-catalyst coating is 8%, and the mass percentage of the catalytically active component is 4.4%. The mass ratio of noble metal to transition metal in the catalytic active component is 1:10, the molar ratio of noble metal Rh / Pd is 1:11, and the molar ratio of transition metal Co / Ni is 1:2; the γ-Al in the cocatalyst coating 2 o 3 With rare earth composite oxide (Ce-Zr-M-O x ) with a mass ratio of 1:0.5, wherein the metal M in the rare earth composite oxide is Pr, and the element molar ratio of Ce / Zr / M is 1:3:0.2.

[0037] (1) Pretreatment of the carrier

[0038] Put the cordierite honeycomb ceramic carrier into the HCl solution with a mass percentage of 10% for surface modification treatment, place it on a resistance furnace and heat it to boiling, wash the surface layer and the residual acid in the holes with water after cooling, put Dry in the oven for later use.

[0039] (2) Preparation of co...

Embodiment 3

[0048] Based on the mass of the cordierite carrier, the mass percentage of the co-catalyst coating is 14%, and the mass percentage of the catalytically active component is 2.1%. The mass ratio of noble metal to transition metal in the catalytic active component is 1:20, the molar ratio of noble metal Rh / Pd is 1:4.5, and the molar ratio of transition metal Co / Ni is 1:1; the γ-Al in the cocatalyst coating 2 o 3 With rare earth composite oxide (Ce-Zr-M-O x ) with a mass ratio of 1:1.38, wherein the metal M in the rare earth composite oxide is Nd, and the element molar ratio of Ce / Zr / M is 1:0.66:0.05.

[0049] (1) Pretreatment of the carrier

[0050] Put the cordierite honeycomb ceramic carrier into 5% H 2 SO 4 Surface modification treatment in the solution, placed on a resistance furnace and heated to boiling, after cooling, wash the surface layer and residual acid in the pores with water, and put it in an oven to dry for later use;

[0051] (2) Preparation of co-catalyst co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com