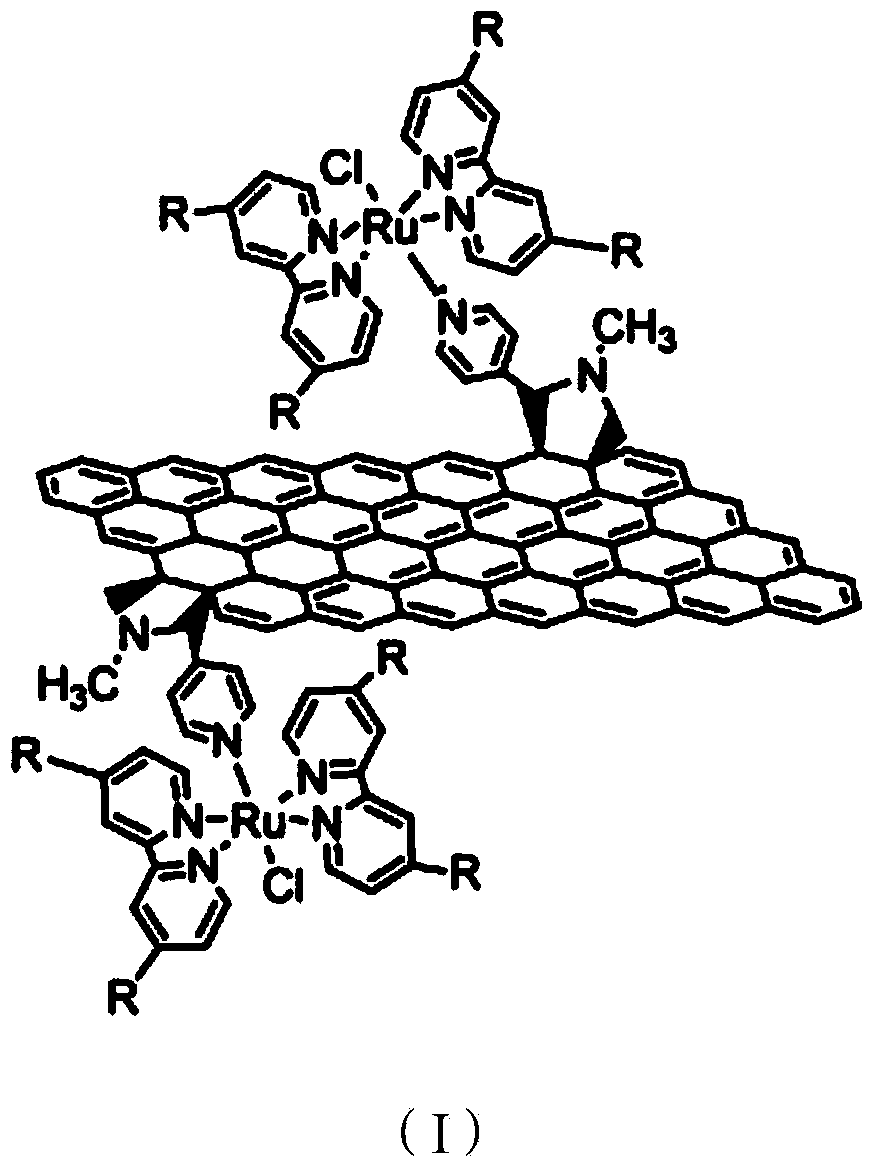

Bipyridyl ruthenium complex covalent functionalized graphene photo-catalyst and preparation method thereof

A bipyridine ruthenium complex and photocatalyst technology, applied in the field of photofunctional catalytic materials, can solve the problems of high requirements for production equipment, large negative impact on the environment, and harsh reaction conditions, and achieve low requirements for reaction conditions, good stability, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

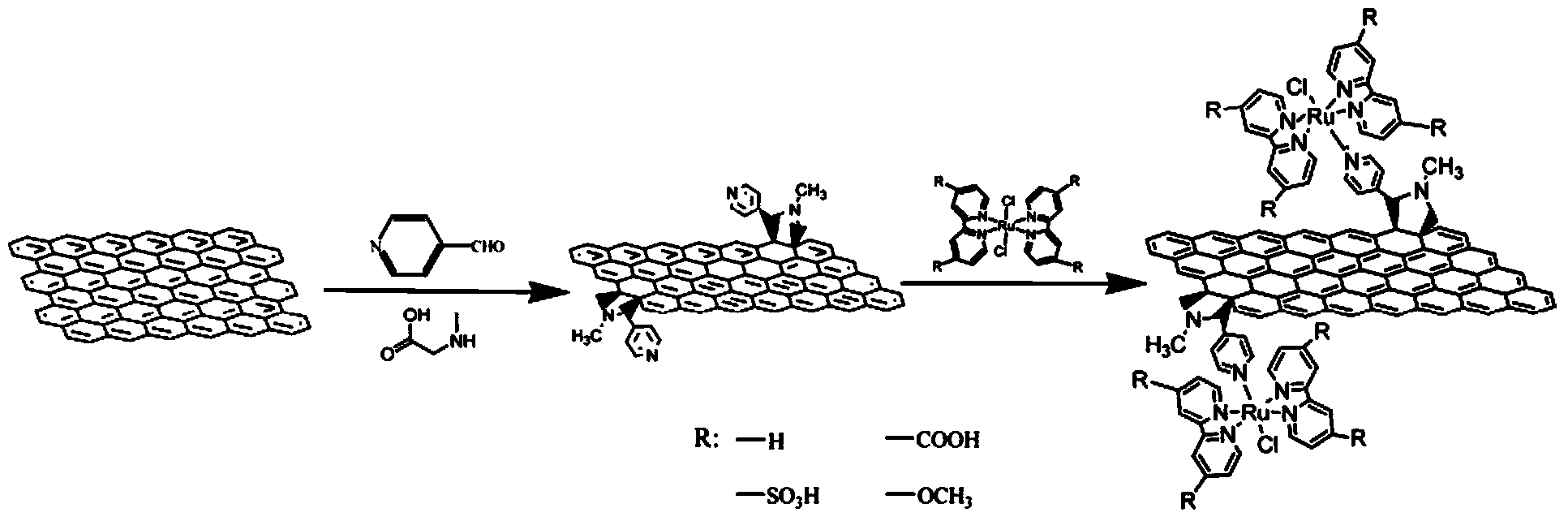

[0029] Using 50mg graphite as raw material and 100mL N-methylpyrrolidone (NMP) as dispersant, ultrasonically disperse at room temperature for 30h. Then high-speed centrifugation, the supernatant was taken, and the concentration of the obtained graphene dispersion was about 0.2 mg / mL, and the yield was about 40%.

[0030] Measure 100mL of graphene dispersion (0.2mg / mL), add it to a 250mL three-necked flask, heat to 160°C, stir for 30min under nitrogen protection, add 33mg N-methylglycine and 34mg aldehyde pyridine mixture , added once every 24h, added a total of 100mg N-methylglycine and 112mg aldehyde pyridine mixture, and continued stirring for 5 days. After the reaction is completed, cool to room temperature, filter the reaction mixture, wash the solid repeatedly with acetone and ethanol, and dry it under vacuum at room temperature to obtain a graphene-based cycloaddition intermediate compound. The yield is about 8%.

[0031] Add 2 mg of the above-mentioned graphene-based ...

Embodiment 2

[0034] Using 50mg graphite as raw material and 100mL N-methylpyrrolidone (NMP) as dispersant, ultrasonically disperse at room temperature for 30h. Then high-speed centrifugation, the supernatant was taken, and the concentration of the obtained graphene dispersion was about 0.2 mg / mL, and the yield was about 40%.

[0035] Measure 100mL of graphene dispersion (0.2mg / mL), add it to a 250mL three-necked flask, heat to 160°C, stir for 30min under nitrogen protection, add 33mg N-methylglycine and 34mg aldehyde pyridine mixture , added once every 24h, added a total of 100mg N-methylglycine and 112mg aldehyde pyridine mixture, and continued stirring for 5 days. After the reaction is completed, cool to room temperature, filter the reaction mixture, wash the solid repeatedly with acetone and ethanol, and dry it under vacuum at room temperature to obtain a graphene-based cycloaddition intermediate compound. The yield is about 8%.

[0036] Add 2 mg of the above-mentioned graphene-based ...

Embodiment 3

[0040] Using 50mg graphite as raw material and 100mL N-methylpyrrolidone (NMP) as dispersant, ultrasonically disperse at room temperature for 30h. Then high-speed centrifugation, the supernatant was taken, and the concentration of the obtained graphene dispersion was about 0.2 mg / mL, and the yield was about 40%.

[0041] Measure 100mL of graphene dispersion (0.2mg / mL), add it to a 250mL three-necked flask, heat to 160°C, stir for 30min under nitrogen protection, add 33mg N-methylglycine and 34mg aldehyde pyridine mixture , Repeated addition every 24h, added a total of 100mg N-methylglycine and 112mg aldehyde pyridine mixture, and continued stirring for 3 days. After the reaction is completed, cool to room temperature, filter the reaction mixture, wash the solid repeatedly with acetone and ethanol, and dry it under vacuum at room temperature to obtain a graphene-based cycloaddition intermediate compound. The yield is about 8%.

[0042] Add 2 mg of the above-mentioned graphene-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com