Dimethyl malonate industrial wastewater treatment and resource recovery method

A technology for dimethyl malonate and waste water production, which is applied to chemical instruments and methods, preparation of organic compounds, ammonia compounds, etc., can solve problems such as waste of resources, environmental pollution, etc., and achieves reduction of environmental protection pressure, production cost, Effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

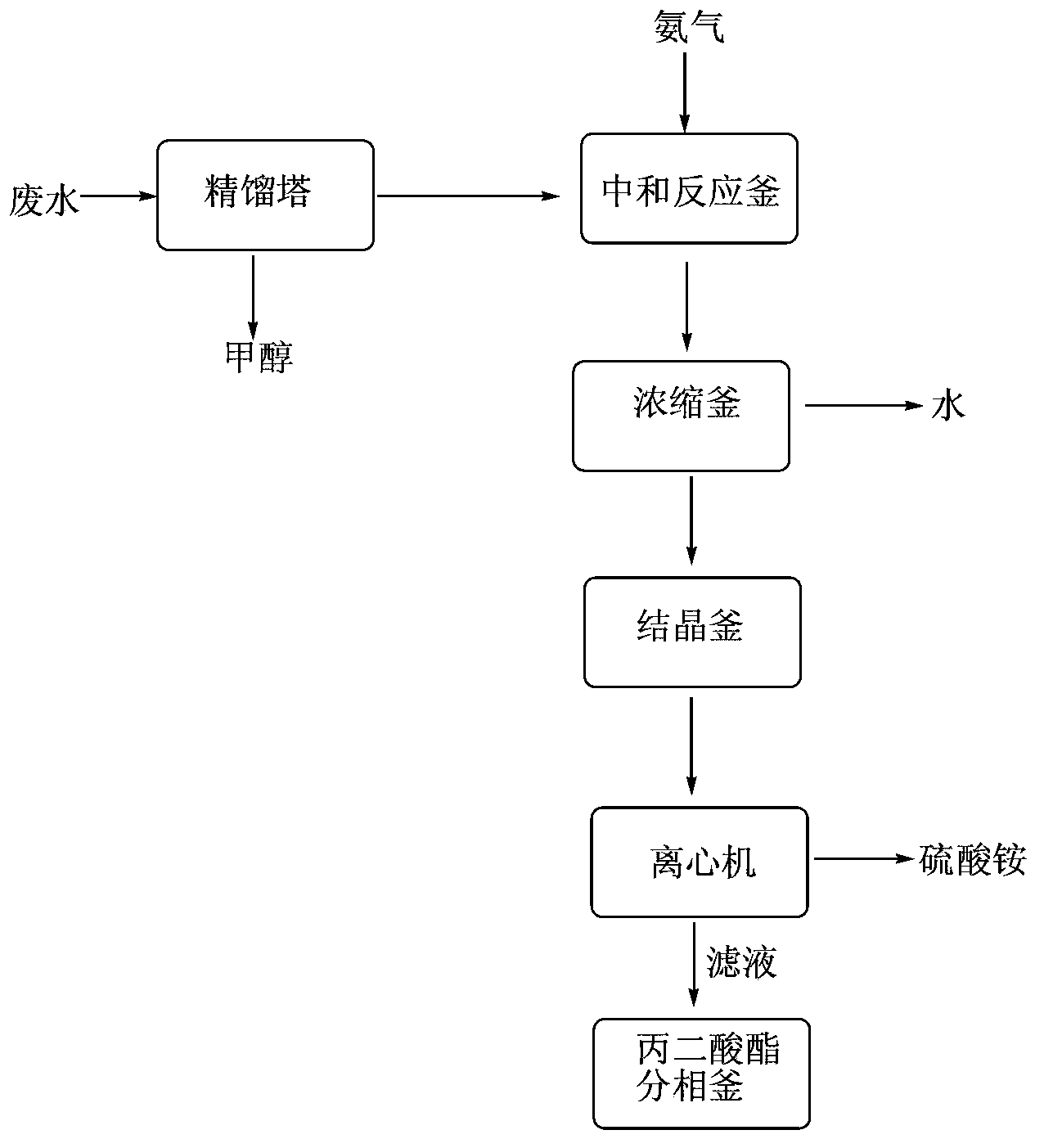

[0023] The following will refer to figure 1 , further illustrate the present invention by embodiment 1:

[0024] (1) Methanol recovery: 2000kg of dimethyl malonate production wastewater (8.6% methanol content, equivalent to 172kg; 23.5% sulfuric acid content, equivalent to 470kg; 32.4% ammonium bisulfate content, equivalent to 640.8kg) was transferred to the rectification tower, Atmospheric distillation yielded 152kg of methanol with a content of 99.3%, a water content of 0.2%, and a recovery rate of 87.8%;

[0025] (2) Neutralization: Transfer the wastewater after recovering methanol to the neutralization reactor, lower it to room temperature, keep the temperature not exceeding 60°C, and pass through ammonia gas to neutralize to pH=5.5;

[0026] (3) Recovery of ammonium sulfate: steam 150kg of neutralized waste water under reduced pressure, then cool to 0°C to crystallize, then centrifuge to obtain solid ammonium sulfate, wash with 100kg of water, and dry to obtain 978kg of ...

Embodiment 2

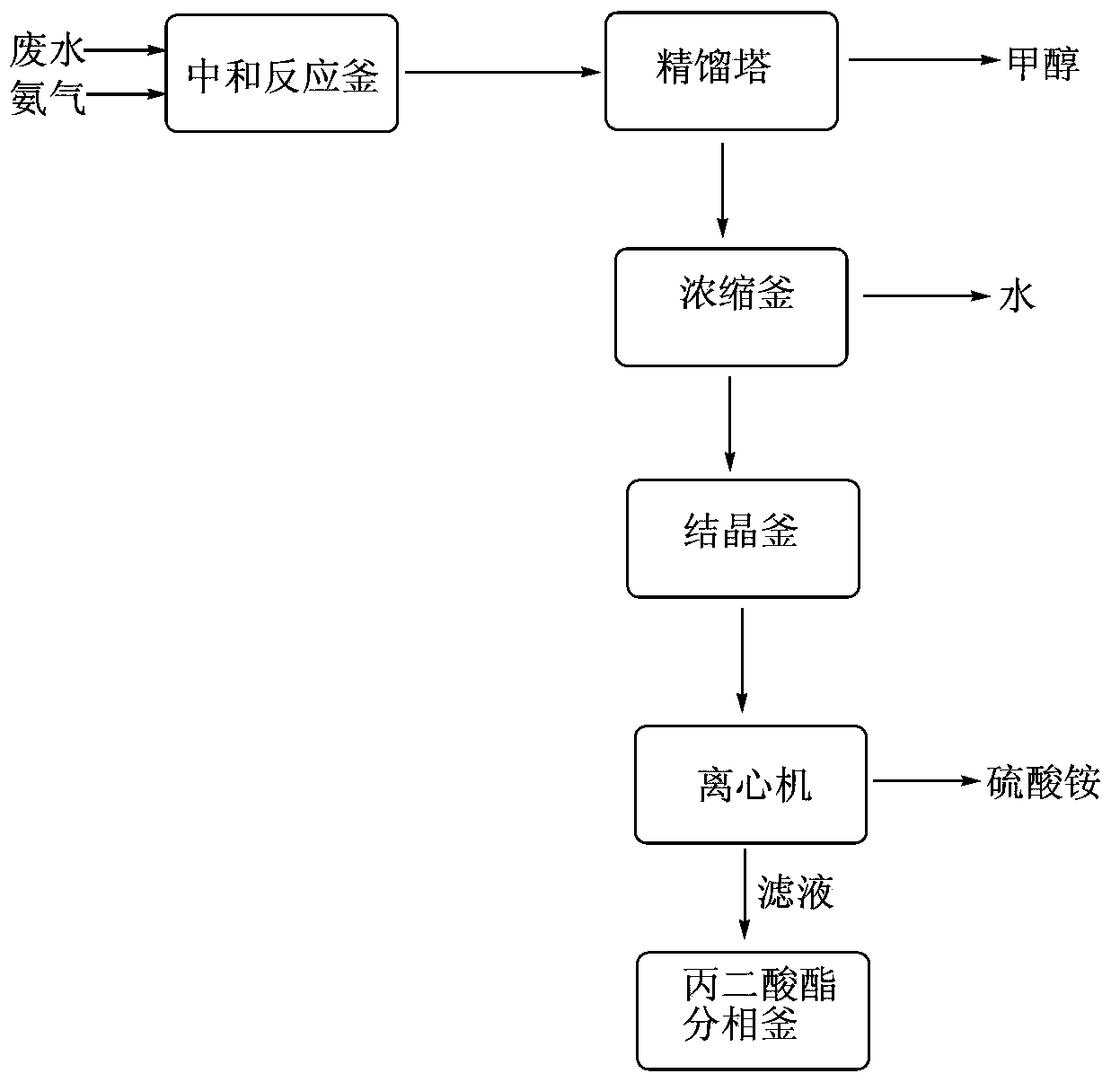

[0028] The following will refer to figure 2 , further illustrate the present invention by embodiment 2:

[0029] (1) Neutralization: Transfer 2000kg of dimethyl malonate production wastewater (8.6% methanol content, equivalent to 172kg; 23.5% sulfuric acid content, equivalent to 470kg; 32.4% ammonium bisulfate content, equivalent to 640.8kg) to the neutralization reactor , keep the temperature not exceeding 60°C and pass through ammonia gas to neutralize to pH=5.7;

[0030] (2) Methanol recovery: transfer the neutralized wastewater to a rectification tower, and rectify at atmospheric pressure to obtain 149kg of methanol, with a content of 99.1%, a water content of 0.3%, and a recovery rate of 85.7%;

[0031] (3) Ammonium sulfate recovery: Distill 150kg of water from the waste water after recovery of methanol under reduced pressure, then cool to 0°C to crystallize, then centrifuge to obtain solid ammonium sulfate, wash with 100kg of water, and dry to obtain 985kg of ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com