Rare earth polymer luminescent material with Tpy as neutral ligand, and preparation and application thereof

A technology of rare earth polymers and neutral ligands, applied in luminescent materials, compounds containing group 3/13 elements of the periodic table, semiconductor/solid-state device manufacturing, etc., can solve unstable quality and performance, low brightness and efficiency , difficulty in preparation and other issues, to achieve the effect of improving electroluminescence and electrical storage performance, small steric hindrance effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 Synthesis of 4-(4-vinylbenzyloxy)benzaldehyde

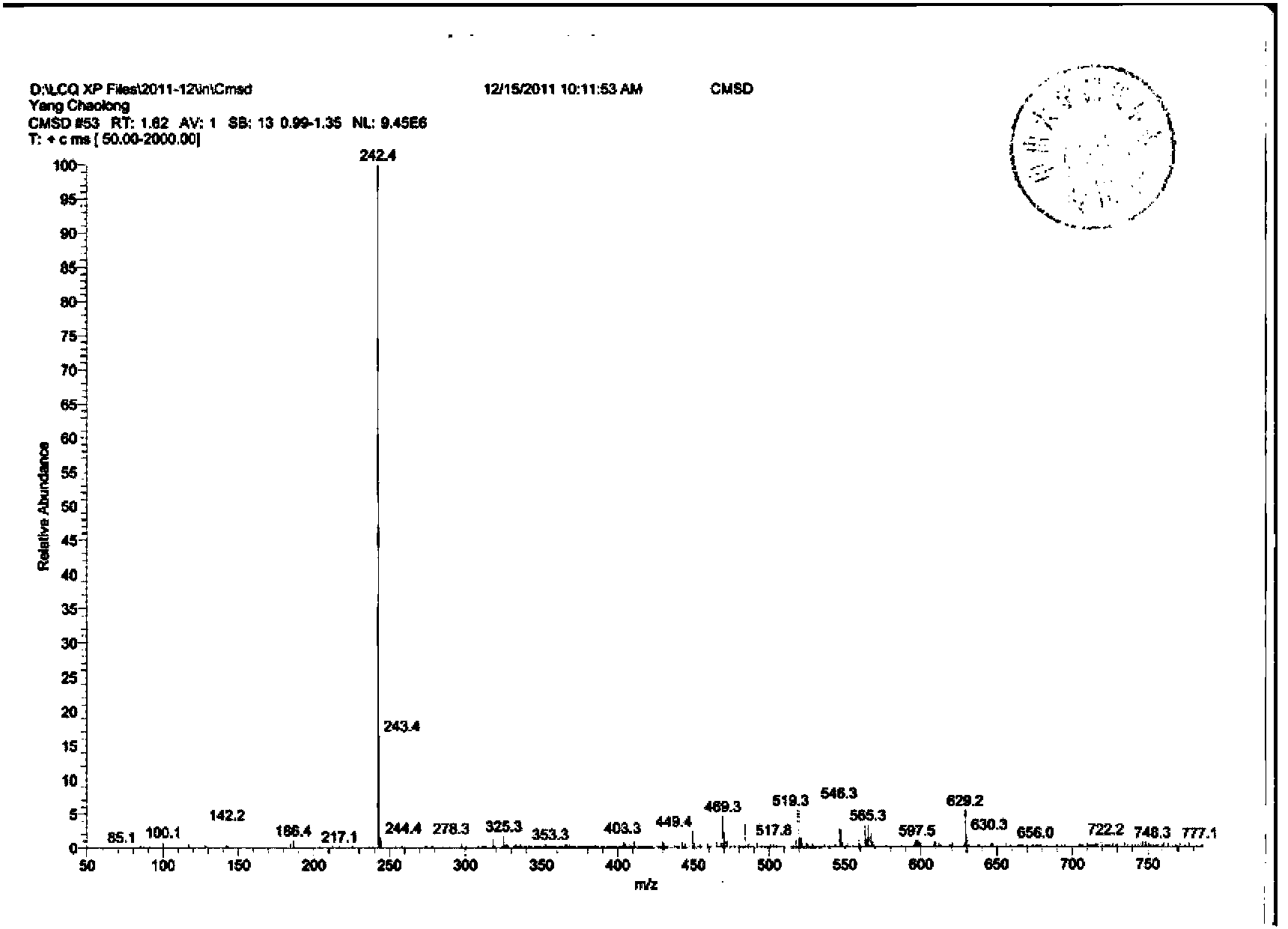

[0067] 4.89 grams of p-hydroxybenzaldehyde (40mmol) and 7.16 grams of 4-vinylbenzyl chloride (40mmol) were added to a 250mL one-necked flask, completely dissolved with 100mL of DMF, then 2.25 grams of KOH (40mmol) was added, and stirred at room temperature for 12 hours, After the reaction, the obtained solution was added to 800 mL of distilled water, and a large amount of precipitates were precipitated, filtered, washed with 50 mL of distilled water for 3 times, and vacuum-dried at 60°C. In order to remove excess 4-vinylbenzyl chloride, the dried product was washed three times with 30 mL of n-hexane, and the obtained solid was dried to obtain 8.11 g of the product, with a yield of 85%. 1 H NMR (400MHz CDCl 3 ):5.14(s,2H);5.27-5.29(d,1H,J HH =11);5.75-5.80(d,1H,J HH =18);6.69-6.76(dd,1H,J HH =18, J HH =12);7.06-7.09(d,2H,J HH =9);7.38-7.46(dd,4H,J HH =8,J HH =8);7.83-7.85(d,2H,J HH =8);9.89(s,1H).ESI-MS:m...

Embodiment 2

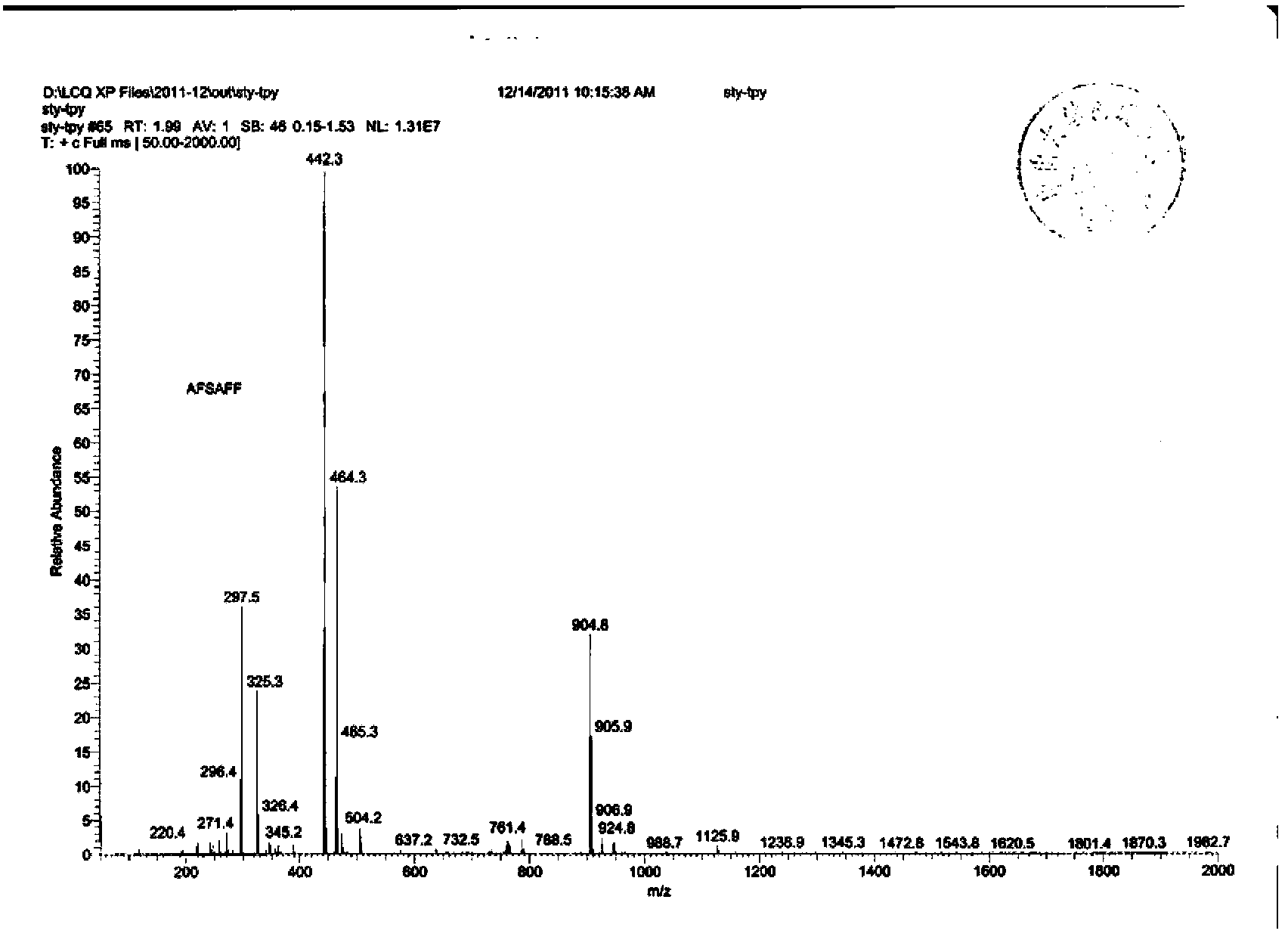

[0068] Example 2 Synthesis of polymerizable tpy ligands

[0069] 2.38 grams of 4-(4-vinylbenzyloxy)benzaldehyde (10mmol) and 2.42 grams of 2-acetylpyridine (20mmol) were added together in a 250mL three-necked flask with magnetic stirring, then 100mL of absolute ethanol was added, and ultrasonic Allow the reactants to dissolve completely, then add 1.55 g of KOH (85%, 20 mmol) and 30 mL of ammonia solution (29.3, 25 mmol), stir at room temperature for 12 hours, filter after the reaction, and wash the resulting solid three times with 60 mL of absolute ethanol, and dry Obtain milky white solid powder 2.73 grams, productive rate 62%. 1 H NMR (400MHz CDCl 3 ):8.65-8.71(m,6H,tpy),7.83-7.88(t,4H,ArH),7.40-7.45(m,4H,ArH),7.26-7.33(t,2H,tpy),7.07-7.09( d,2H,ArH),6.70-6.77(m,1H,CH=CH 2 ),5.75-5.80(d,1H,CH=CH 2 ),5.25-5.28(d,1H,CH=CH 2 ),5.08(S,2H,-CH 2 -). 13 C NMR (100MHz CDCl 3):159.5,156.2,155.7,149.5,148.9,137.1,136.8,136.3,130.9,128.4,127.7,126.4,123.7,121.3,118.2,115.1,114....

Embodiment 3

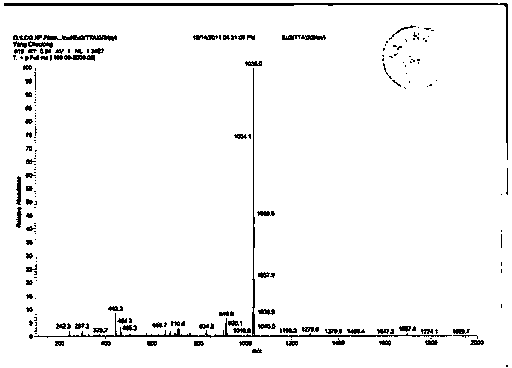

[0070] Embodiment 3 Synthesis of polymerizable monomer tpy rare earth europium complex

[0071] In a round-bottomed flask with a reflux device and a stirring device, dissolve 3 mmol of β-diketone in tetrahydrofuran, then add 3 mmol of hydrogen sodium oxide, and react at 65°C for 20 minutes, then add one equivalent of β-diketone dissolved in ethanol EuCl in 3 2H 2 O solution, reacted at 65°C for 1h, then added 1mmol of polymerizable tpy compound containing a small amount of polymerization inhibitor to the aforementioned reaction system, and then reacted at 65°C for 6h, cooled to room temperature after the reaction, and then vacuum desolventized, After washing with appropriate amount of distilled water and ethanol, and vacuum drying, 0.93 g of a polymerizable tpy rare earth europium complex was obtained. The product was bright yellow, and the yield was 74%. (Found: C, 50.08; H, 2.94; N, 3.19.EuC 54 h 35 f 9 N 3 o 7 S 3 [EuVTPY]requires C,51.60;H,2.81;N,3.35%). 1 H NMR (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com