Composite industrial gasification formed coke binder and preparation method of formed coke

A gasification and composite technology, which is applied in the field of composite industrial gasification coke binder and its coke preparation, can solve the problems of high production cost and poor bonding performance, and achieve low production cost and excellent performance , to overcome the effect of non-adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

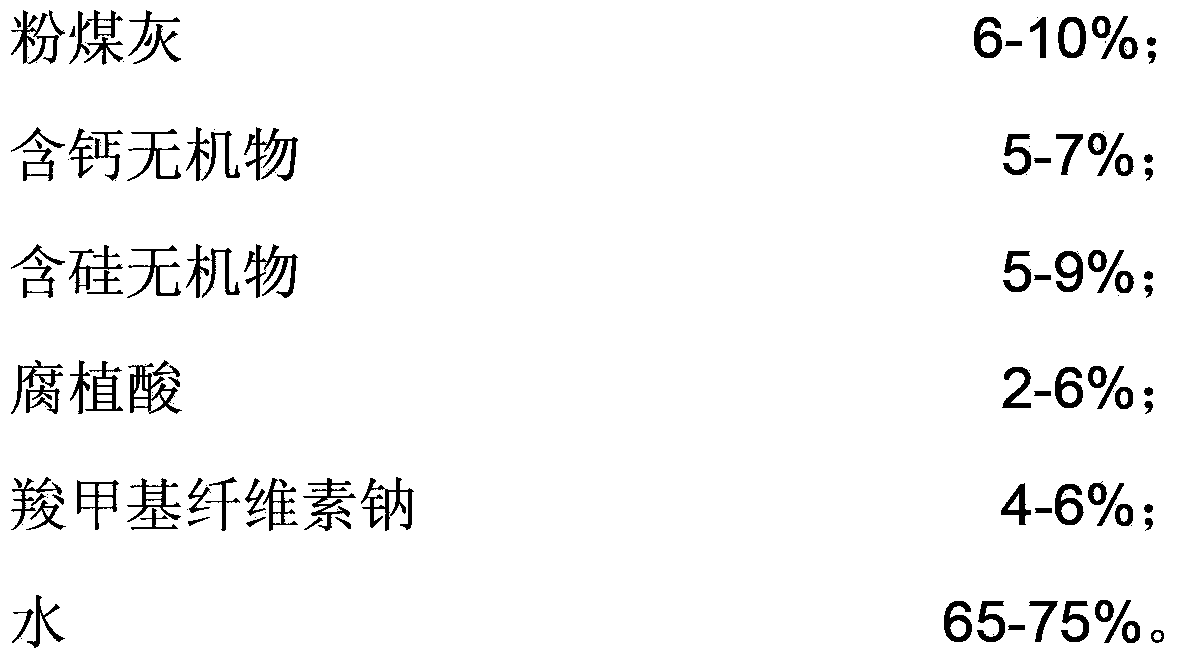

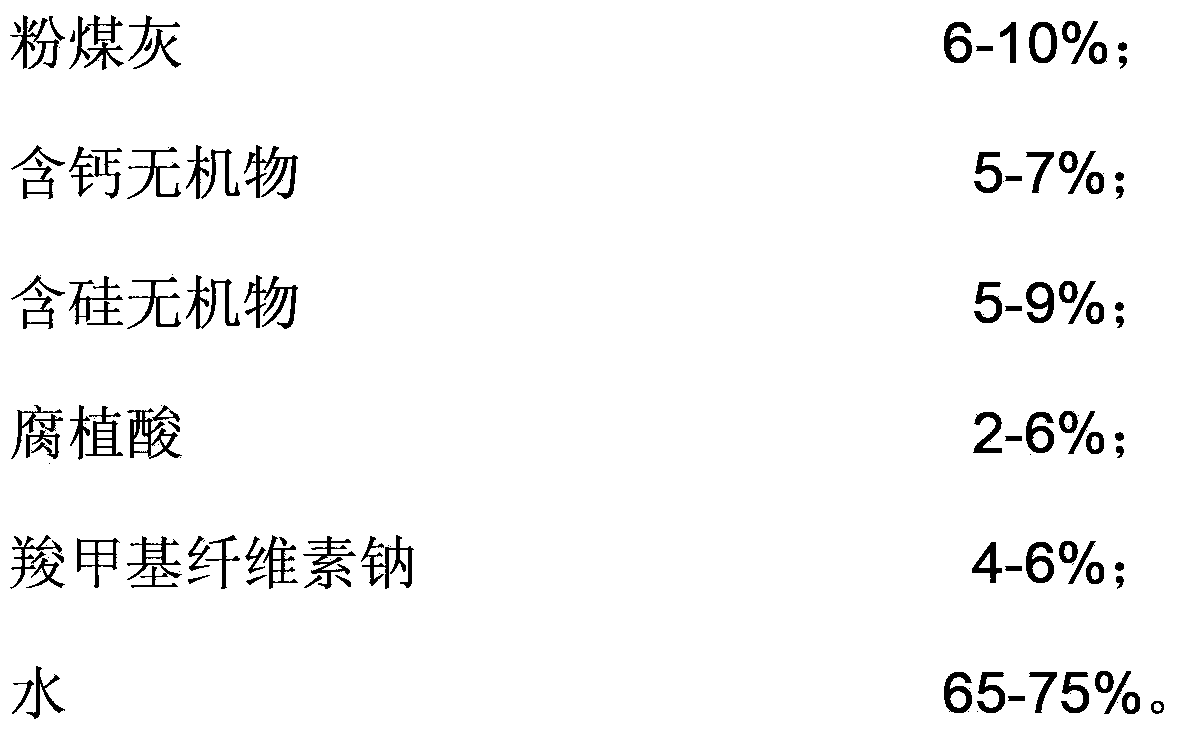

Method used

Image

Examples

Embodiment 1

[0039] (1) Put 65 parts of water in the reaction kettle, heat up, and when the temperature reaches 80°C, add 10 parts of fly ash, 6 parts of lime powder and 7 parts of sodium silicate into the reaction kettle, and stir at a speed of 85r / min , when the temperature rises to 100°C, continue to stir for 70min under this temperature condition;

[0040] (2) Add 6 parts of humic acid and 6 parts of sodium carboxymethylcellulose into the reaction kettle, and continue to stir at this speed for 90 minutes at 100°C to fully mix these ingredients;

[0041](3) After the solution in step (2) is cooled to room temperature, the composite gasification coke binder of the present invention is obtained.

[0042] (4) Break the coke powder until the particle size is below 3mm, put it and the binder in step (3) in a kneading pot, stir for 10 minutes, and mix them evenly. The dosage ratio (parts by mass) is: powder coke 87 parts, 13 parts of binder;

[0043] (5) Send the mixture to a roller press, ...

Embodiment 2

[0045] (1) Put 70 parts of water in the reaction kettle, heat up, and when the temperature reaches 65°C, add 8 parts of fly ash, 7 parts of calcium hydroxide and 9 parts of silica sol into the reaction kettle, and stir at a speed of 75r / min , when the temperature rises to 95°C, continue to stir for 60min under this temperature condition;

[0046] (2) Add 2 parts of humic acid and 4 parts of sodium carboxymethylcellulose into the reaction kettle, and continue to stir at this speed for 75 minutes at 95°C to fully mix these ingredients;

[0047] (3) After the solution in step (2) is cooled to room temperature, the composite gasification coke binder of the present invention is obtained.

[0048] (4) Break the coke powder until the particle size is below 3mm, put it and the binder in step (3) in a kneading pot, stir for 10 minutes, and mix them evenly. The dosage ratio (parts by mass) is: powder coke 84 parts, 16 parts of binder;

[0049] (5) Send the mixture to a roller press, p...

Embodiment 3

[0051] (1) Put 75 parts of water in the reaction kettle, heat up, and when the temperature reaches 50°C, add 6 parts of fly ash, 5 parts of calcium aluminate cement and 5 parts of sodium fluorosilicate into the reaction kettle, at 65r / min Stir at a constant speed, wait for the temperature to rise to 90°C, and continue to stir for 50 minutes at this temperature;

[0052] (2) Add 4 parts of humic acid and 5 parts of sodium carboxymethylcellulose into the reaction kettle, and continue to stir at this speed for 60 minutes at 90°C to fully mix these ingredients;

[0053] (3) After the solution in step (2) is cooled to room temperature, the composite gasification coke binder of the present invention is obtained.

[0054] (4) Break the coke powder until the particle size is below 3mm, put it and the binder in step (3) in a kneading pot, stir for 10 minutes, and mix them evenly. The dosage ratio (parts by mass) is: powder coke 81 parts, 19 parts of binder;

[0055] (5) Send the mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com