Battery separator and preparation method thereof

A battery separator and porous membrane technology, applied in the field of battery separator and its preparation, can solve the problems of accelerating battery thermal runaway, battery short circuit, battery fire, etc., and achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the battery separator provided in the embodiment of the present invention comprises the following steps:

[0021] S11, providing polyolefin porous membrane;

[0022] S12, attaching an oxidizing agent to the surface of the polyolefin porous membrane;

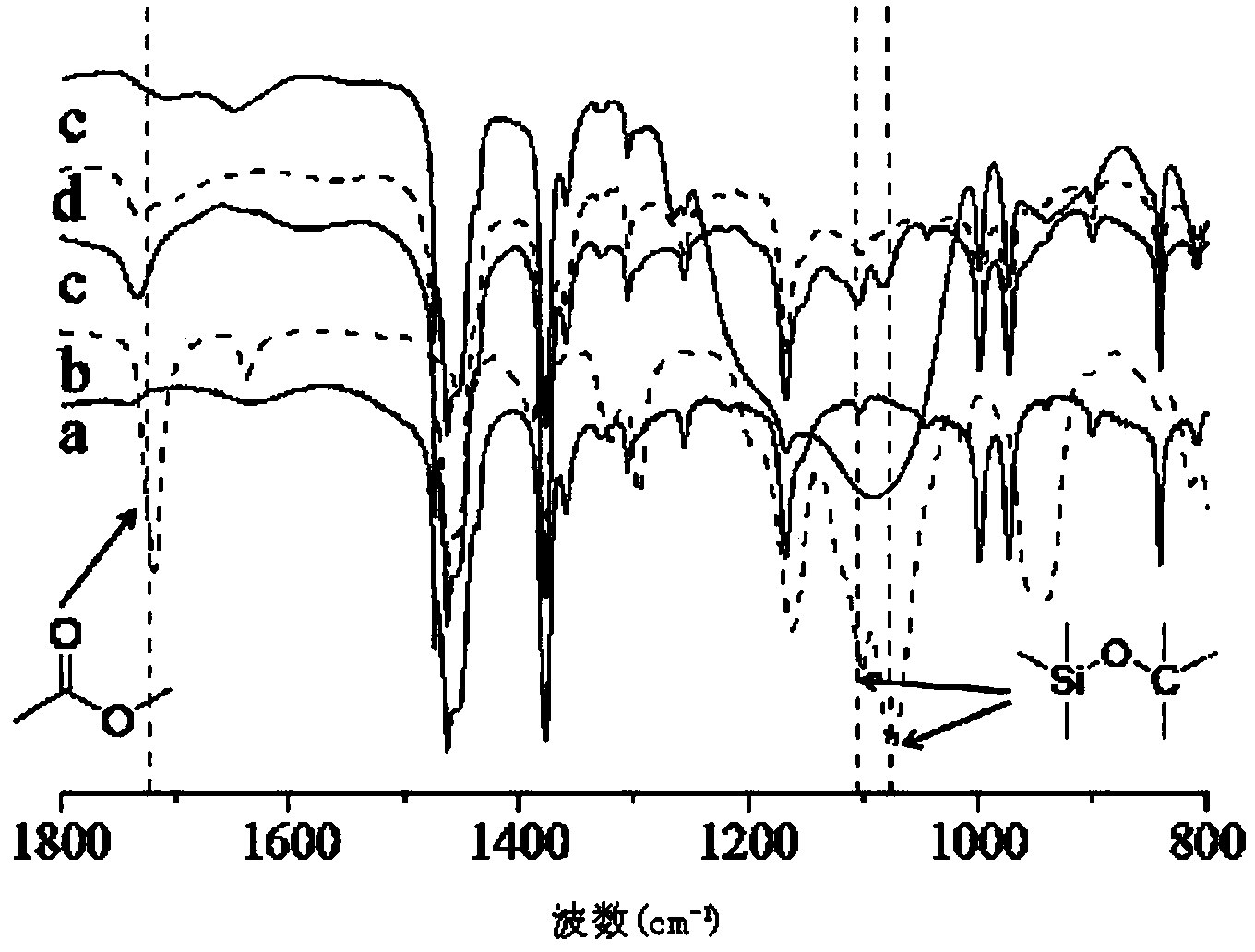

[0023] S13, providing a liquid phase medium having an organosiloxane compound, the organosiloxane compound includes a methacryloxy group and at least two alkoxy groups, the alkoxy group and the methacryloxy group are respectively Connecting with silicon atoms, heating the polyolefin porous membrane with oxidant adsorbed on the surface in the liquid medium, polymerizing the organosiloxane compound, and chemically grafting with the polyolefin porous membrane;

[0024] S14, providing an acidic environment or an alkaline environment, placing the grafted polyolefin porous membrane in an acidic environment or an alkaline environment, causing the siloxane groups to undergo condensation reactions to form...

Embodiment 1

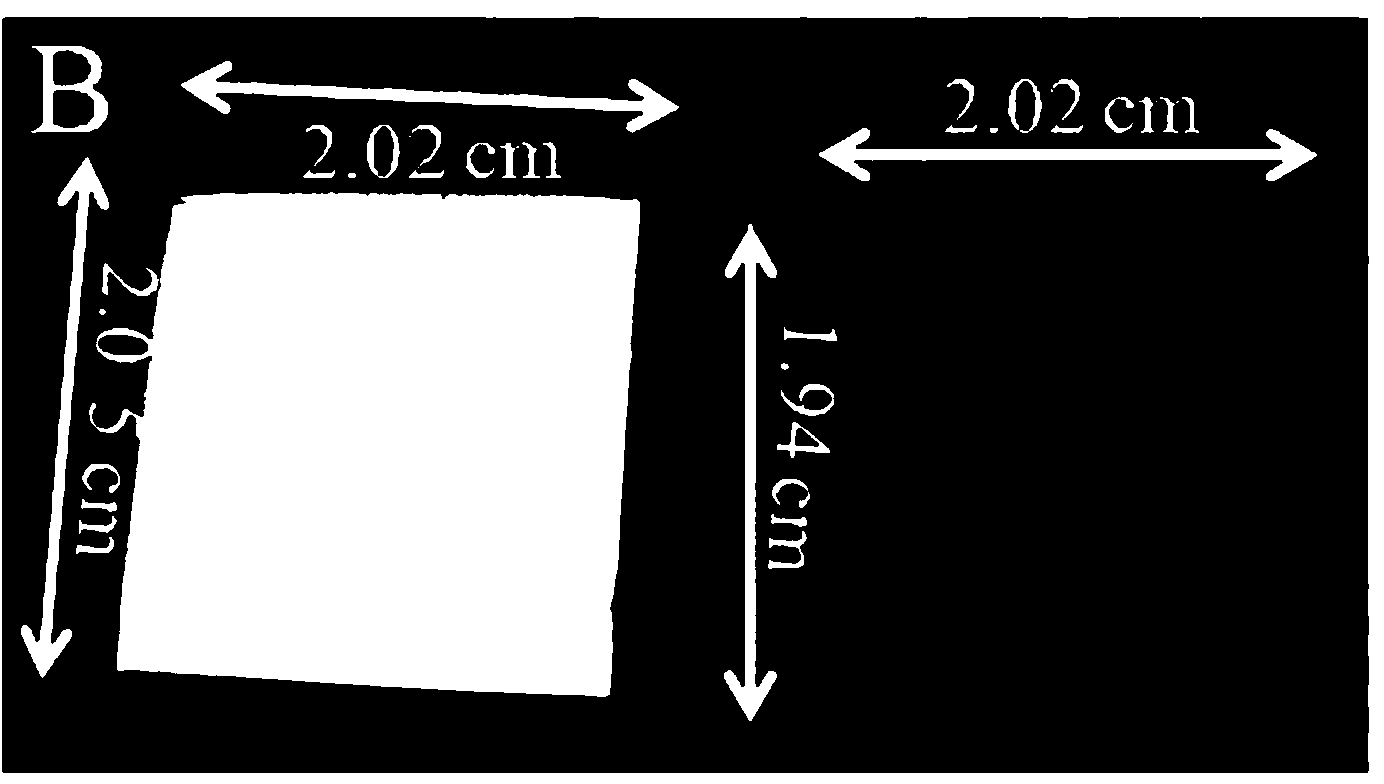

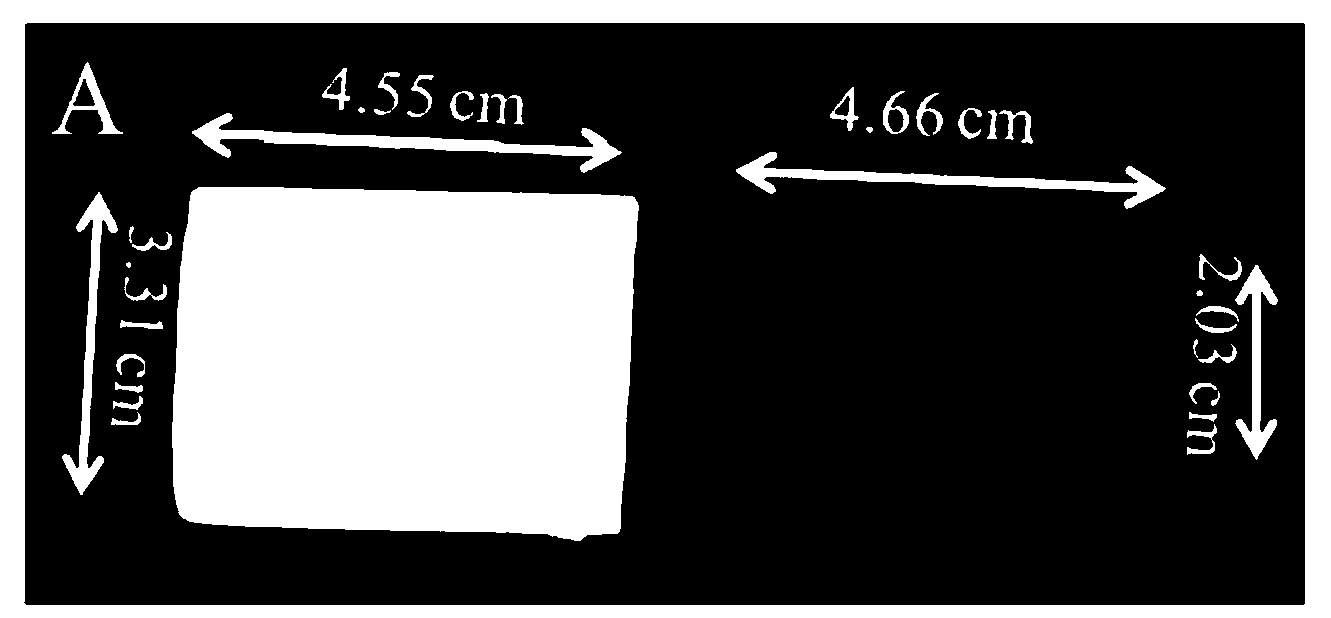

[0072] Soak the Celgard-2300 diaphragm in the acetone solution of BPO (concentration: 2.5%, w / w) for 1 hour, take it out, dry it at room temperature, and put it into TEPM aqueous solution (concentration: 1%, v / v), Heated at 90°C for 2 hours, took it out, placed it in acetone for ultrasonic vibration to remove residual TEPM, and finally dried it in vacuum for 12 hours. The resulting membrane sample was labeled Celgard-PTEPM-2h.

Embodiment 2

[0074] It is basically the same as Example 1, except that it is heated at 90° C. for 4 hours, and the obtained membrane sample is marked as Celgard-PTEPM-4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com