Anion-cation double-doped lithium iron phosphate anode material and preparation method thereof

A lithium iron phosphate, cation technology, applied in battery electrodes, electrical components, circuits, etc., to achieve large ionic conductivity, improve electrochemical performance, and reduce blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

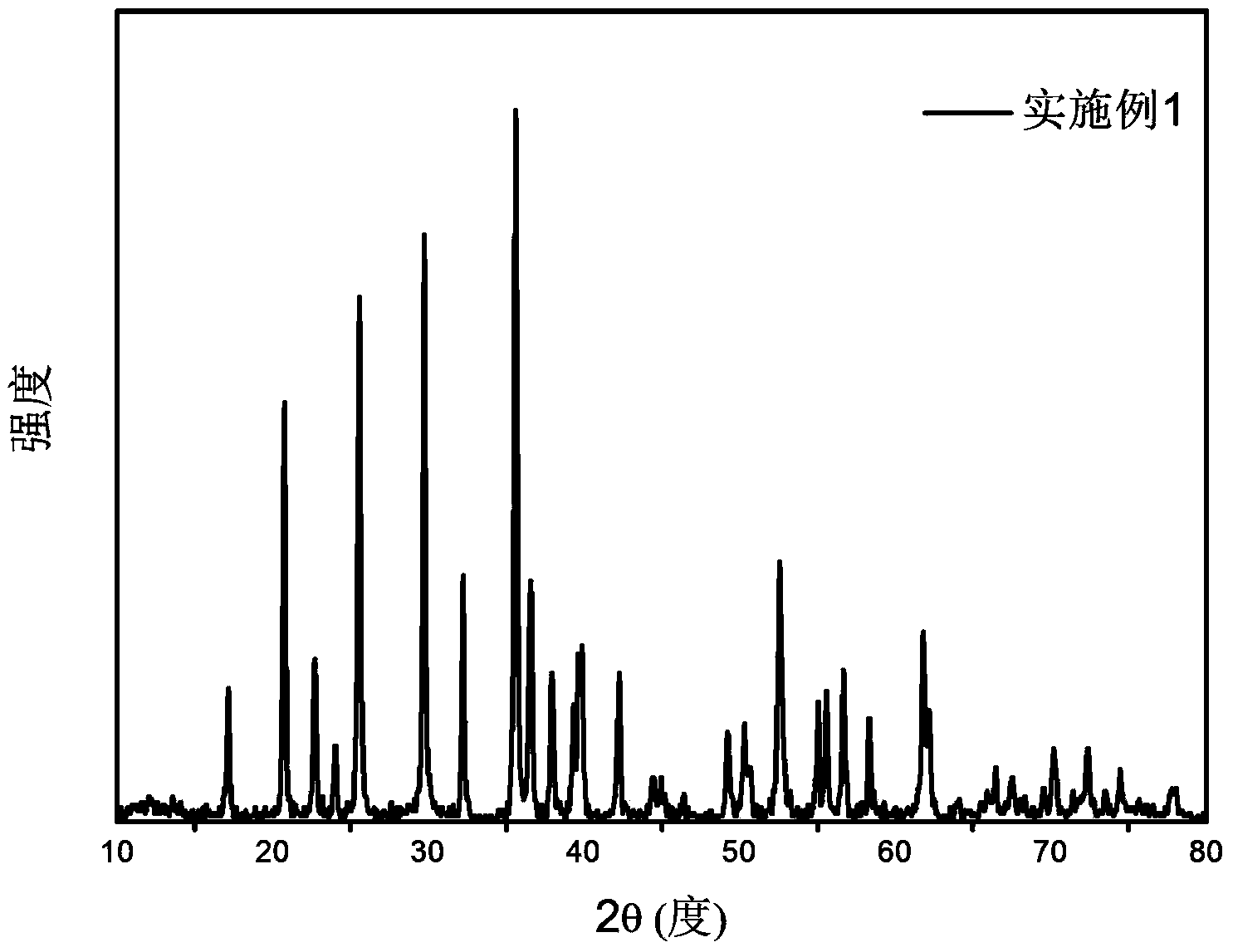

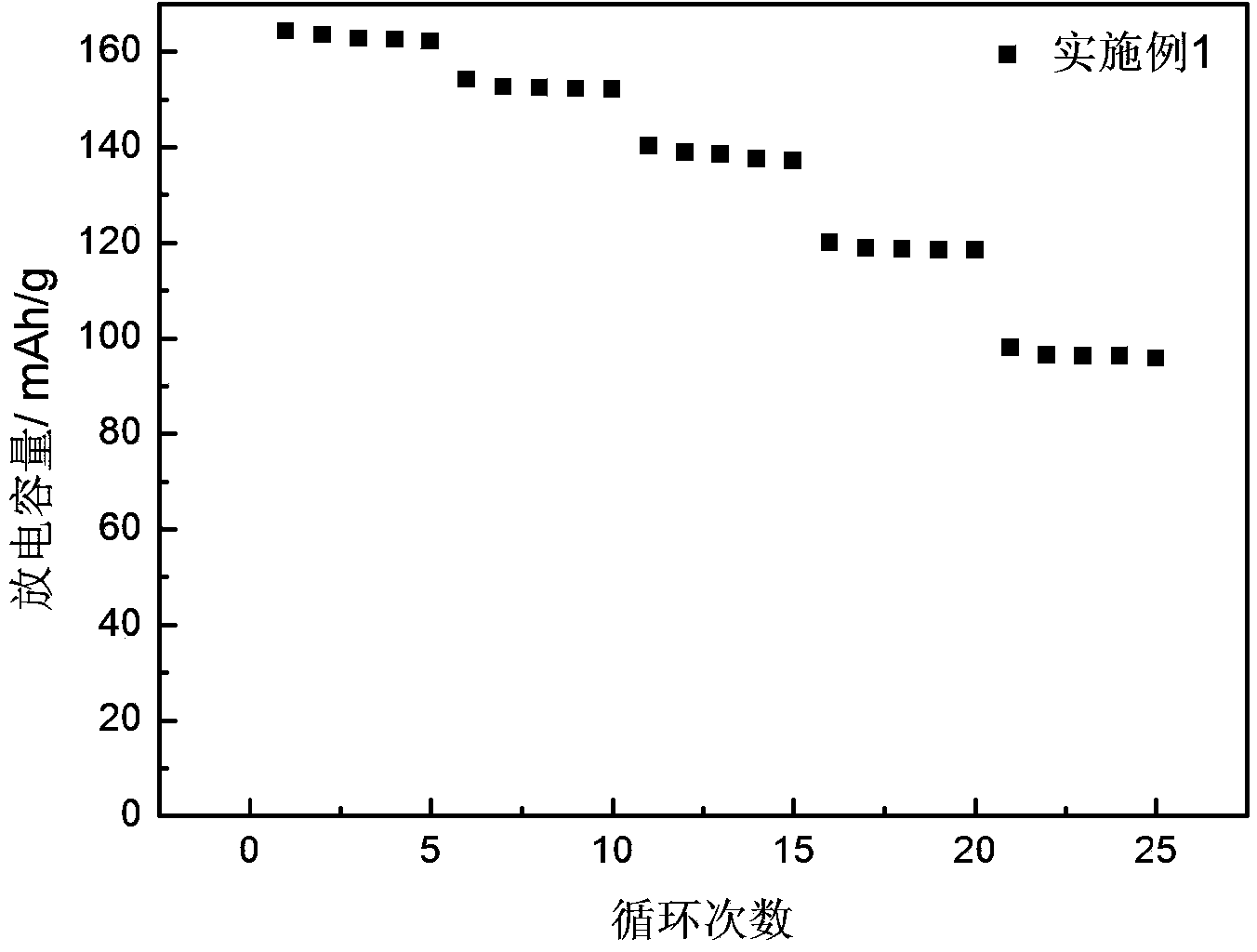

Embodiment 1

[0035] Add 0.097 mol of lithium carbonate, 0.092 mol of ferrous oxalate, 0.004 mol of magnesium nitrate, 0.099 mol of lithium dihydrogen phosphate, 0.003 mol of lithium fluoride and 14 g of citric acid into the ball mill jar, and ball mill at a speed of 280 r / min 8 hours. After the ball-milled mixture is dried, it is ground into a powder. The powder is pre-fired at 400 degrees Celsius for 6 hours under the protection of argon, fired at 700 degrees Celsius for 8 hours, and then naturally cooled to room temperature to obtain anion-cation double-doped lithium iron phosphate, the molecular formula is LiFe 0.92 Mg 0.08 (PO 4 ) 0.99 f 0.03 / C. The measured capacities of the material at 1C, 5C, and 10C rates are 154 mAh / g, 120 mAh / g, and 98 mAh / g, respectively, and the capacity retention rate after 150 cycles at 1C rate is 98.4%.

Embodiment 2

[0037] Add 0.094 mol of lithium nitrate, 0.095 mol of ferrous oxalate, 0.005 mol of magnesium nitrate, 0.098 mol of lithium dihydrogen phosphate, 0.006 mol of lithium fluoride and 17 g of citric acid into the ball mill tank, and ball mill at a speed of 250 r / min 8 hours. After the ball-milled mixture is dried, it is ground into a powder. The powder is pre-fired at 300 degrees Celsius for 4 hours under the protection of argon, fired at 650 degrees Celsius for 10 hours, and then naturally cooled to room temperature to obtain anion and cation double-doped lithium iron phosphate, the molecular formula is LiFe 0.95 Mg 0.05 (PO 4 ) 0.98 f 0.06 / C. The measured capacities of the material at 1C, 5C, and 10C rates are 149 mAh / g, 116 mAh / g, and 93 mAh / g, respectively, and the capacity retention rate after 150 cycles at 1C rate is 98.2%.

Embodiment 3

[0039] Add 0.085 mol of lithium carbonate, 0.090 mol of ferrous oxalate, 0.010 mol of magnesium nitrate, 0.095 mol of lithium dihydrogen phosphate, 0.015 mol of lithium fluoride and 17 g of sucrose into the ball milling tank, and ball mill for 8 hours at a speed of 300 r / min. Hour. After the ball-milled mixture is dried, it is ground into a powder. The powder is pre-fired at 400 degrees Celsius for 6 hours under the protection of argon, fired at 750 degrees Celsius for 12 hours, and then naturally cooled to room temperature to obtain anion and cation double-doped lithium iron phosphate, the molecular formula is LiFe 0.9 Mg 0.1 (PO 4 ) 0.95 f 0.15 / C. The measured capacities of the material at 1C, 5C, and 10C rates are 150 mAh / g, 112 mAh / g, and 86 mAh / g, respectively, and the capacity retention rate after 150 cycles at 1C rate is 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com