Preparation and application of hollow tree-like bismuth oxide-bismuth sulfide complex

A technology of bismuth oxide and bismuth sulfide, which is applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as toxic and harmful organic intermediates, increase the difficulty of post-processing and environmental pollution, and achieve The effect of cheap raw materials, controllable crystal phase and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

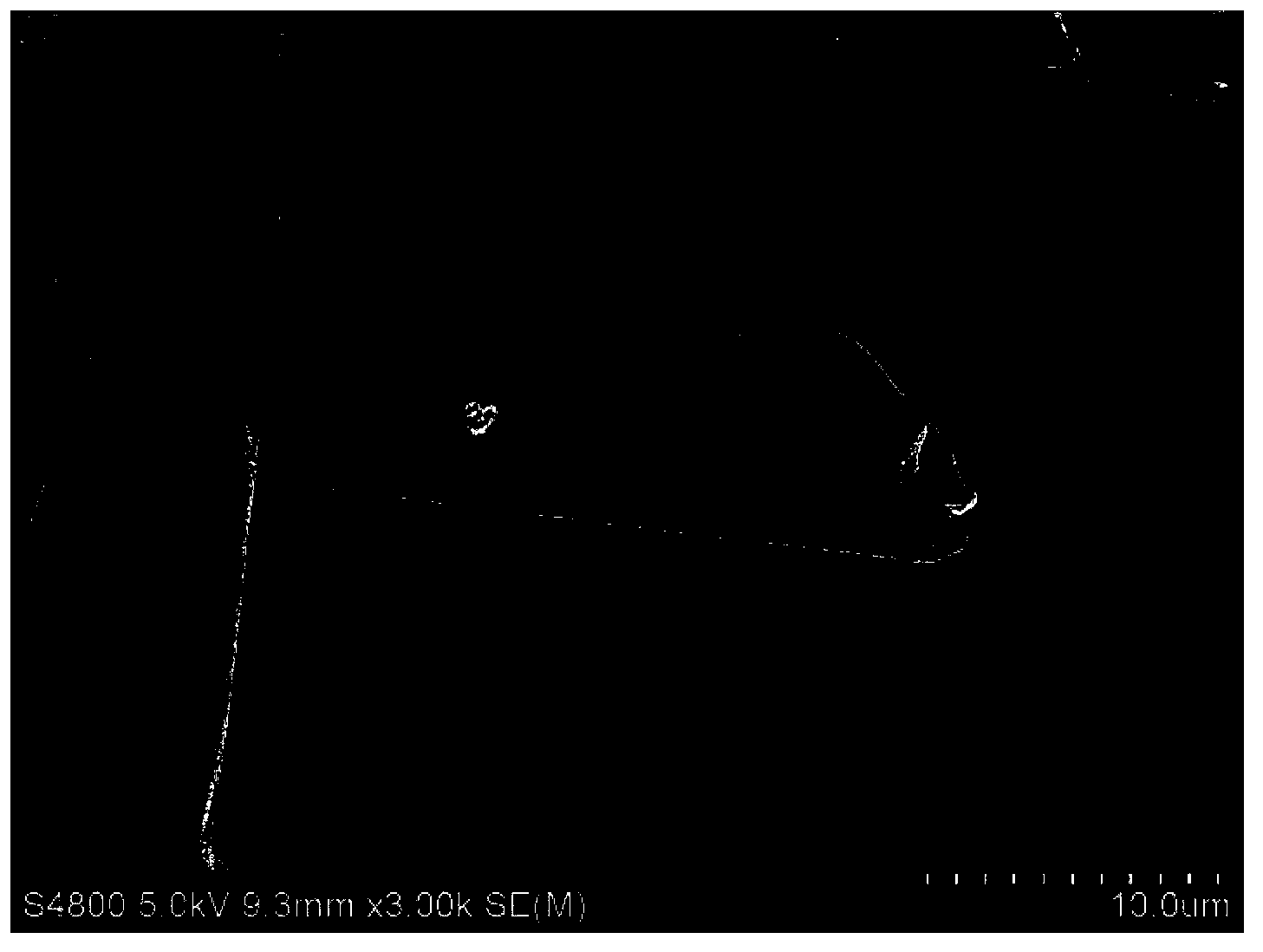

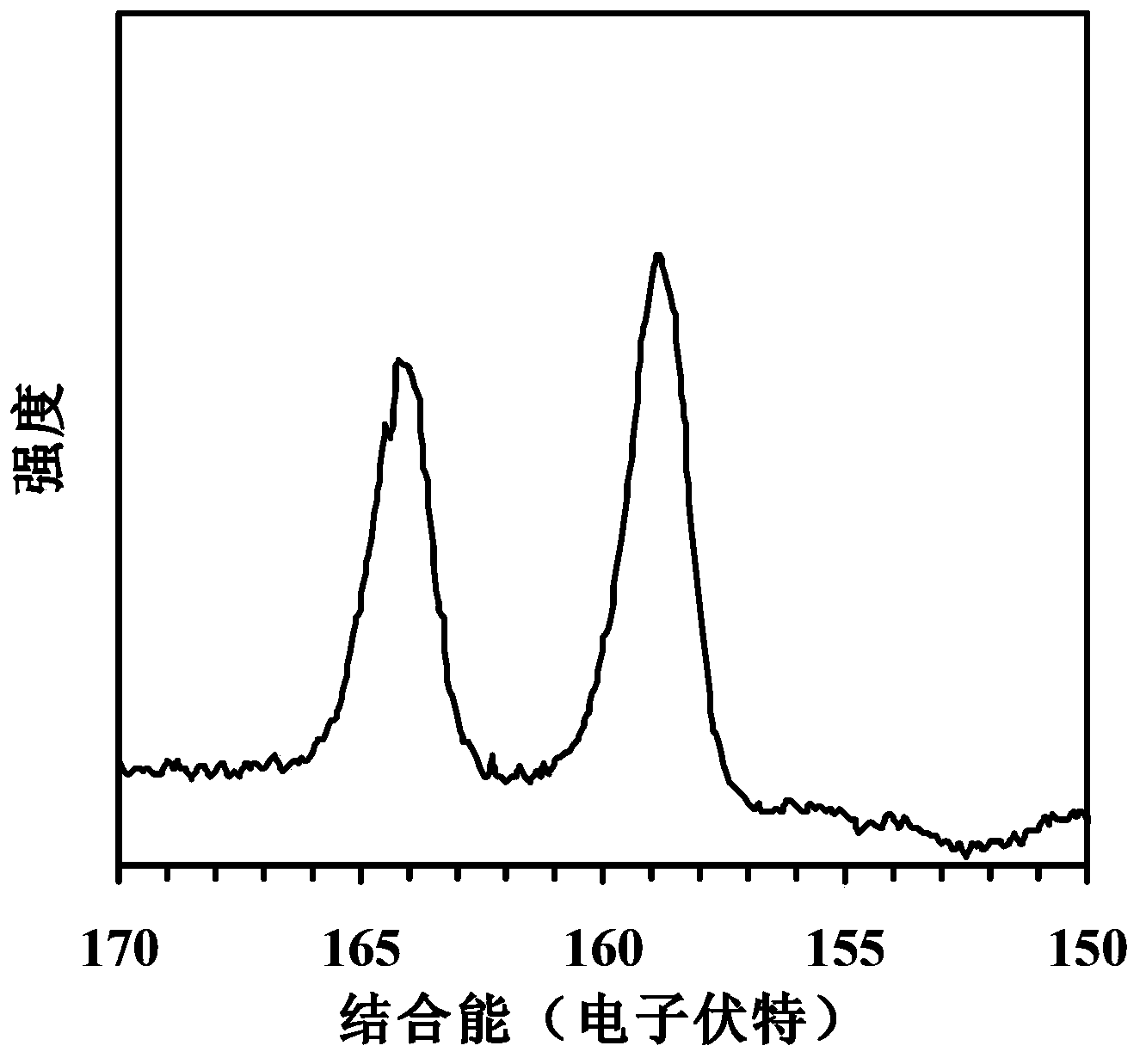

[0024] According to bismuth nitrate pentahydrate in the reaction mixture: nitric acid: the mol ratio of potassium hydroxide is 1:1:4.7, takes by weighing 4.85 grams of bismuth nitrate pentahydrate and is dissolved in nitric acid, after stirring and dissolving, adjust solution pH value with potassium hydroxide solution, Then it was transferred to a 100 ml crystallization reactor for hydrothermal crystallization at 160oC for 6 hours. Filter, wash, dry and roast according to conventional methods to obtain a yellow powder. The yellow powder is characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the obtained product is bismuth oxide, a hollow tube with a length of about 80-150 microns and a diameter of 3-5 microns.

[0025] Take by weighing 1 gram of the above-mentioned hollow tubular bismuth oxide, disperse it in 40 milliliters of deionized water, then add sodium sulfide nonahydrate solution, then transfer the mixed solution to the crystallization...

Embodiment 2

[0030] According to bismuth nitrate pentahydrate in the reaction mixture: nitric acid: the mol ratio of sodium hydroxide is 1:1:4.7, takes by weighing 4.85 grams of bismuth nitrate pentahydrate and is dissolved in nitric acid, after stirring and dissolving, adjust solution pH value with sodium hydroxide solution, Then it was transferred to a 100 ml crystallization reactor for hydrothermal crystallization at 160oC for 6 hours. Filter, wash, dry and roast according to conventional methods to obtain a yellow powder. The yellow powder is characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the obtained product is bismuth oxide, a hollow tube with a length of about 80-150 microns and a diameter of 3-5 microns.

[0031] The preparation method of the hollow dendritic bismuth oxide-bismuth sulfide composite is the same as in Example 1.

[0032] Taking the degradation of rhodamine-B as a model reaction to investigate the photocatalytic activity of the ...

Embodiment 3

[0034] According to the molar ratio of bismuth nitrate pentahydrate in the reaction mixture: nitric acid: mixed alkali solution is 1:1:4.7 (wherein the mixed alkali solution is potassium hydroxide, the mixed solution of ammoniacal liquor), weigh 4.85 grams of bismuth nitrate pentahydrate and dissolve in nitric acid After stirring and dissolving, adjust the pH value of the solution with potassium hydroxide solution, then transfer to a 100 ml crystallization reactor, and conduct hydrothermal crystallization at 160oC for 6 hours. Filter, wash, dry and roast according to conventional methods to obtain a yellow powder. The yellow powder is characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the obtained product is bismuth oxide, a hollow tube with a length of about 80-150 microns and a diameter of 3-5 microns.

[0035]The preparation method of the hollow dendritic bismuth oxide-bismuth sulfide composite is the same as in Example 1.

[0036] Taking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com