Method for removing organic matter under synergy of visible light photoelectric catalysis and three-dimensional electrode/electro-fenton

A three-dimensional electrode and photoelectric catalysis technology, which is applied in chemical instruments and methods, electrochemical water/sewage treatment, light water/sewage treatment, etc., can solve problems such as the inability to directly use visible light synergistic treatment effects, and achieve efficient and rapid degradation of organic pollution , Increase electrocatalytic efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

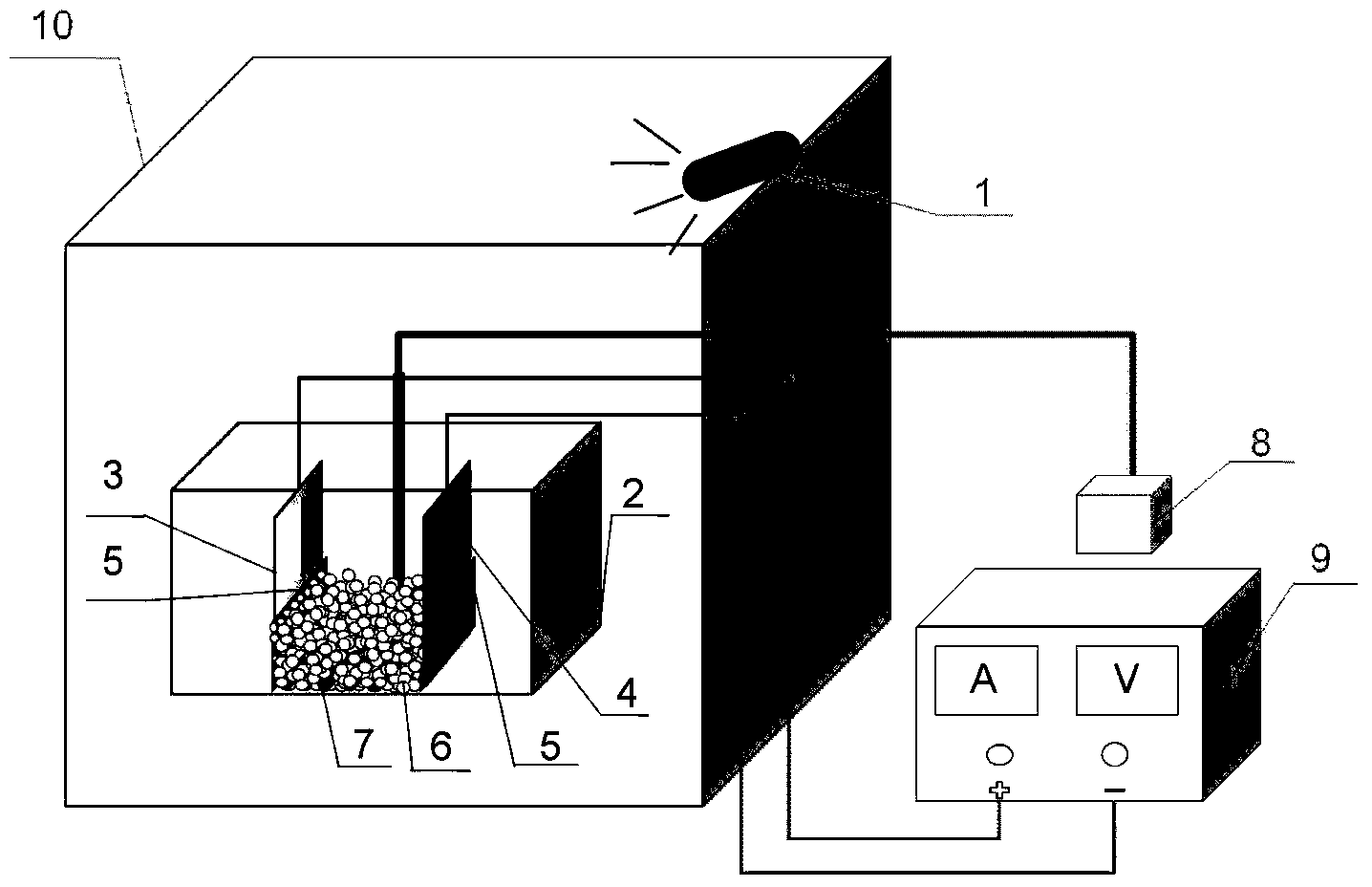

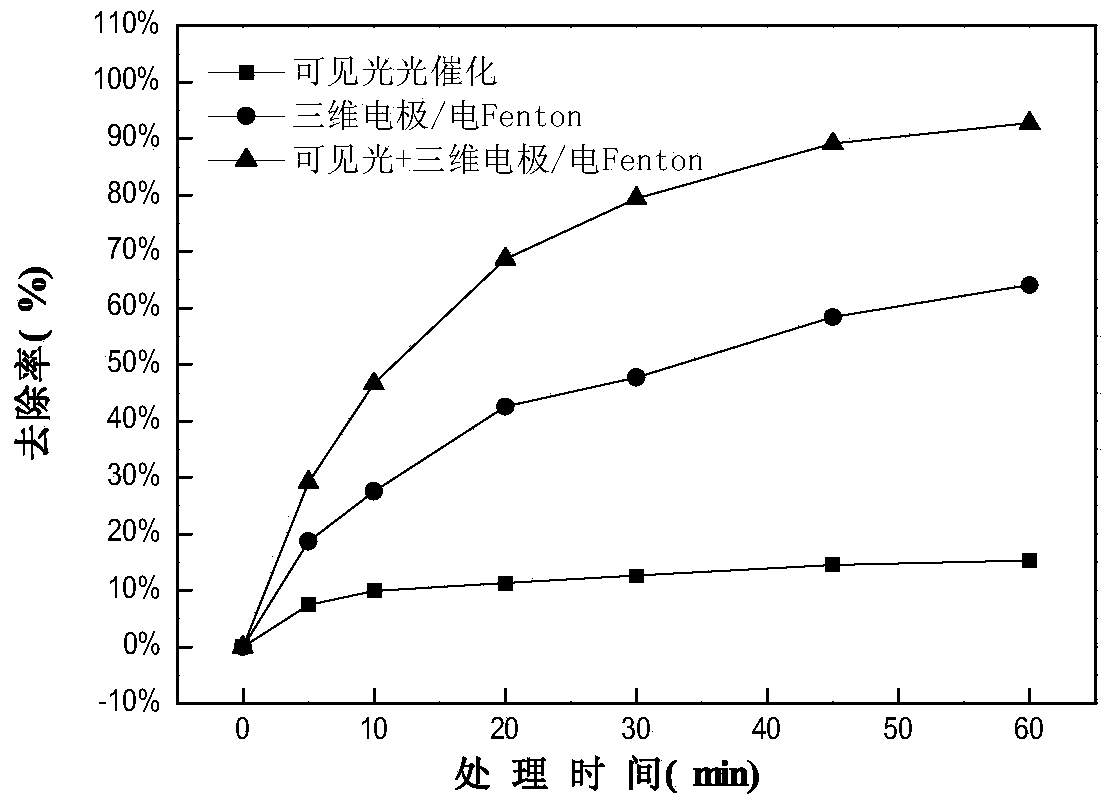

Embodiment 1

[0029] A Visible Light Photoelectrocatalytic Synergistic Three-Dimensional Electrode / Electro-Fenton Removal Method Using TiO 2 The mesoporous film electrode is used as the anode, and the graphite is used as the cathode. The plate spacing between the two electrodes is 4cm. There are two insulating separators inside the cathode and anode plates. The aperture of the insulating separator is 2-2.5mm. The activated carbon-loaded Fe-Ni co-doped particle electrode is filled between the insulating separators. The activated carbon particle electrode is columnar with a diameter of 3-5mm and an aspect ratio of 1:1. The filling amount of the particle electrode is 100g / L. The cathode is aerated through the aeration device, the aeration rate is controlled to 1.5L / min, the voltage between the cathode and the anode is controlled to 30V, and the 150W fluorescent lamp is an externally illuminated light source, which is irradiated at an angle of 60° with the anode plate to form visible light Phot...

Embodiment 2

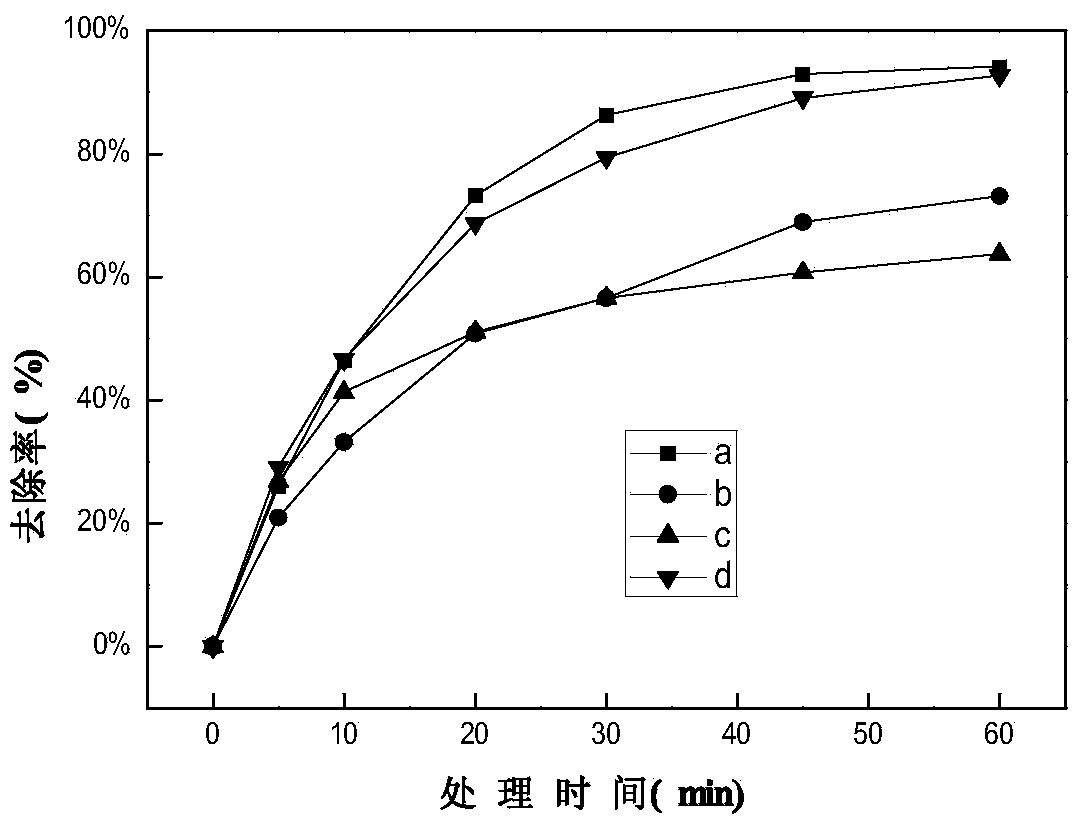

[0031] Example 2. Comparison of removal effects and energy consumption of different plates and particle electrodes.

[0032] In order to comprehensively judge the advantages of the device and method of the present invention in terms of pollutant removal and energy consumption, four groups of comparative experiments were set up in the experiment, and the experimental method was the same as in Example 2. The control simulated visible light source was a 150W xenon lamp; the power supply voltage was 30V, and the aeration rate was 1.5L. / min, the dosage of ferrous iron is 0.05mmol / L, the dosage of anhydrous sodium sulfate is 5g / L, the pH of the solution is 3, the volume of the solution is 400ml, and the dosage of the particle electrode is 100g / L, and the pollutant degradation experiment is carried out. The experimental setup and the average current and energy consumption during the process are shown in Table 1.

[0033] Table 1 Photoelectrocatalytic energy consumption of different ...

Embodiment 3

[0038] A Visible Light Photoelectrocatalytic Synergistic Three-Dimensional Electrode / Electro-Fenton Method for Organic Removal, Fe-Ni Modified TiO 2 The mesoporous film electrode is the anode, graphite is the cathode, the plate spacing between the two electrodes is 6cm, and two insulating partitions are arranged inside the cathode and anode plates, and the aperture of the insulating partition is 2-2.5mm. Activated carbon supported Fe-Co co-doped TiO 2 It is filled between the insulating separators, wherein the activated carbon particle electrode is granular, with a particle diameter of 3-5mm, and the filling amount of the particle electrode is 200g / L. The cathode is aerated through the aeration device, the aeration rate is controlled to 5L / min, the voltage between the cathode and the anode is controlled to 15V, a 60W halogen tungsten lamp externally illuminated light source is applied, and the anode plate is irradiated at an angle of 60°. Visible photoelectric three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com