Dielectric ceramic composition and electronic device

A technology of ceramic composition and electronic components, applied in the direction of fixed capacitor dielectrics, ceramics, components of fixed capacitors, etc., can solve problems such as difficulty in maintaining high electrostatic capacity, low dielectric loss and high AC breakdown voltage, and achieve temperature characteristics and sintering. Good properties, high relative permittivity, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

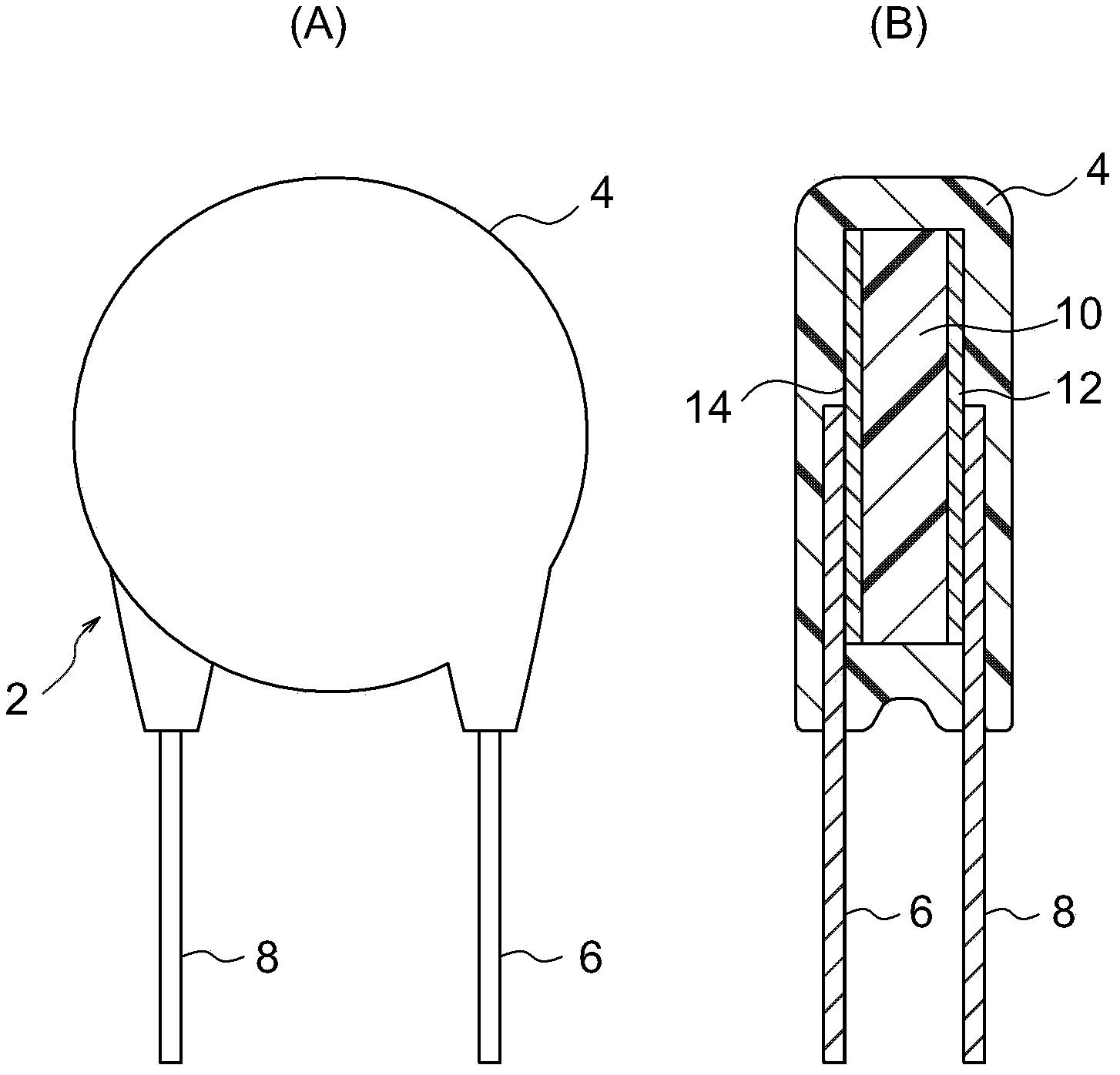

Image

Examples

Embodiment

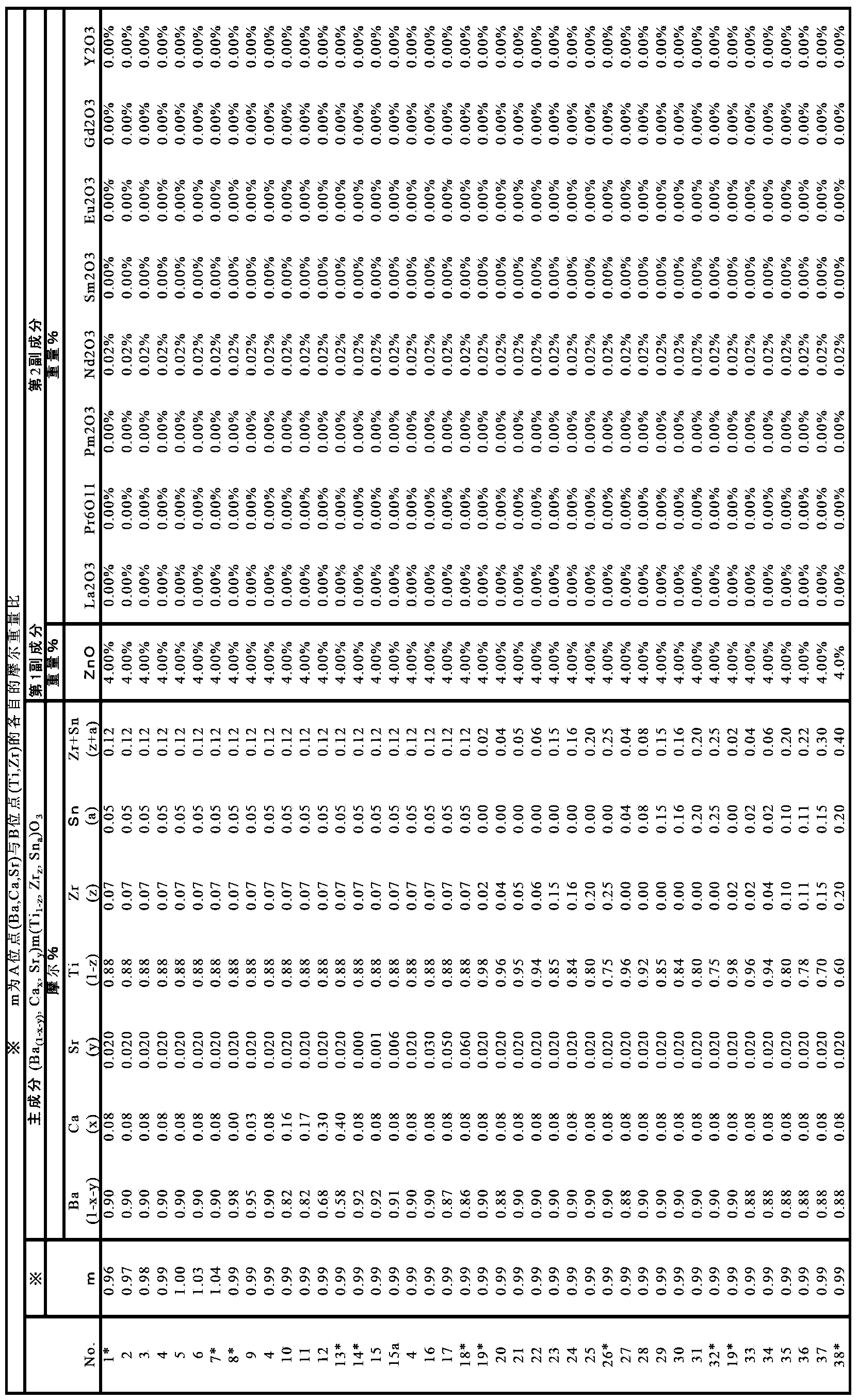

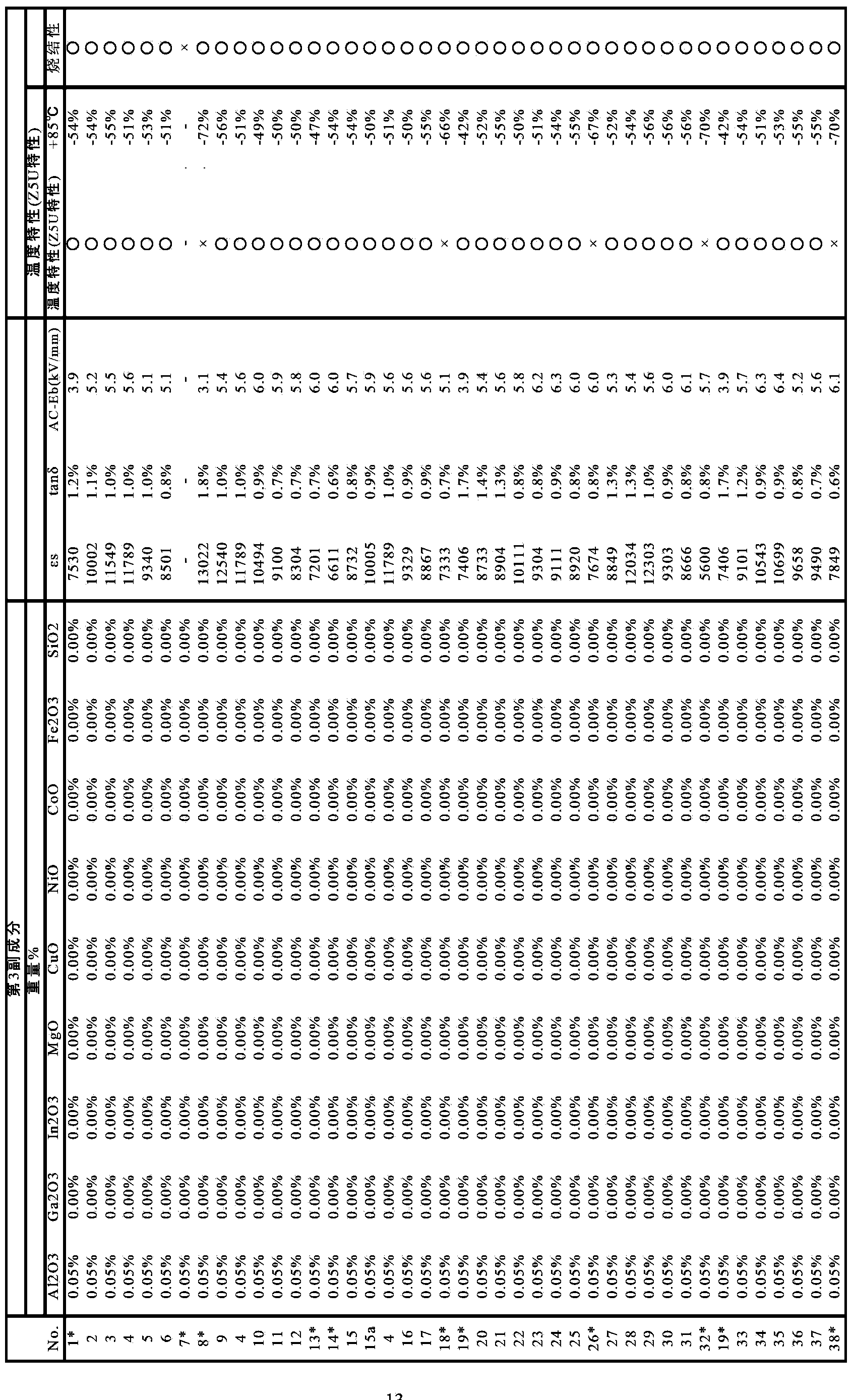

[0071] The present invention will be further described below based on detailed examples, but the present invention is not limited to these examples.

[0072] Sample 1~58

[0073] As the main component raw material, barium carbonate (BaCO 3 ), calcium carbonate (CaCO 3 ), strontium carbonate (SrCO 3 ), titanium oxide (TiO 2 ), zirconia (ZrO 2 ) and tin oxide (SnO 2 ). The main component raw material, ZnO as the first subcomponent raw material, and ZnO as the second subcomponent raw material were respectively prepared so that the composition after firing became the composition shown in Samples 1 to 73 shown in Tables 1 to 4. Rare earth additives are weighed, and the raw material complex is wet-stirred and mixed with a ball mill for 3 hours. After dehydration and drying, it is pre-calcined at a temperature of 1170-1210° C. to cause a chemical reaction.

[0074] In addition, regarding the raw materials of the third subcomponent such as ZnO as the first subcomponent and ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com