Method of preparing titanium dioxide meso-pore material with adjustable pore diameter

A technology of titanium dioxide and mesoporous materials, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the adjustment of titanium dioxide mesoporous pore size and pore size distribution has not been effectively realized, and achieve low cost , good photocatalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Dissolve 3.4 ml of butyl titanate in 5 ml of ethanol, stir well to obtain liquid A; mix 5 ml of water, 5 ml of acetonitrile, 3 ml of acetic acid, and 0.2 ml of acetylacetone, and stir well to obtain liquid B.

[0024] 2) Add liquid A dropwise to liquid B, stir evenly, and age for 2 h to obtain a transparent titanium dioxide sol.

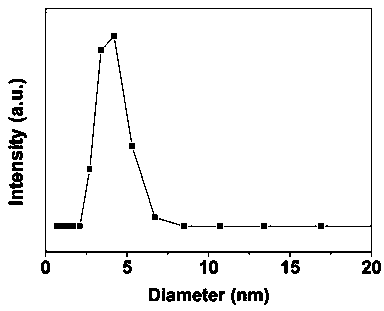

[0025] The transparent titanium dioxide sol shows that the titanium dioxide colloidal particles have smaller size and better dispersibility. The particle size distribution curve of colloidal particles in titanium dioxide colloids measured by dynamic light scattering is shown in Figure 1. It can be seen from the figure that the hydrodynamic diameter of titanium dioxide colloidal particles is 4 nm.

[0026] 3) Pour the titania sol into a petri dish and dry it in the air for 24 h, and then perform a heat treatment at 450 °C for 2 h to obtain a titania mesoporous material.

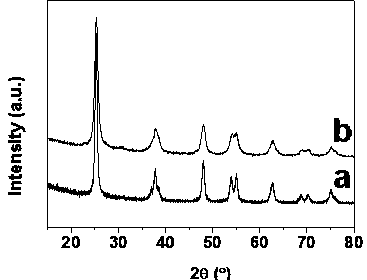

[0027] The X-ray diffraction pattern of the prepared titanium diox...

Embodiment 2

[0029] 1) Dissolve 3.4 ml of butyl titanate in 5 ml of ethanol, stir well to obtain liquid A, dissolve 6 g of Brij-35 in 5 ml of water, 5 ml of acetonitrile, 3 ml of acetic acid, and 0.2 ml of acetylacetone in aqueous solution, Stir evenly to obtain liquid B.

[0030] 2) Add liquid A dropwise to liquid B, stir evenly, and age for 2 h to obtain a transparent titanium dioxide sol.

[0031] 3) Pour the titania sol into a petri dish and dry it in the air for 24 h, and then perform a heat treatment at 450 °C for 2 h to obtain a titania mesoporous material.

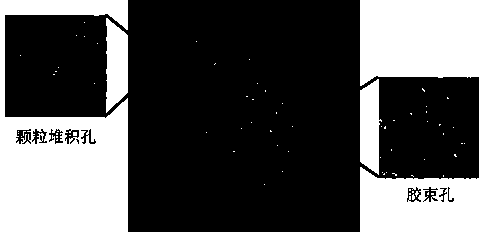

[0032] The X-ray diffraction pattern of the prepared titanium dioxide mesoporous material is shown in the curve b in Figure 2. From the figure, it can be known that the product is anatase phase titanium dioxide. Calculated by Scherrer's formula, the average crystal diameter is 10 nm. The transmission electron micrographs of the prepared titanium dioxide mesoporous materials are as follows: image 3 . It can be seen from the...

Embodiment 3

[0034] 1) Dissolve 1.3 ml of isopropyl titanate in 5 ml of ethanol, stir well to obtain liquid A, dissolve 1 g of CTAB in 8 ml of water, 6 ml of acetonitrile, 2 ml of acetic acid, and 0.3 ml of acetylacetone, and stir Obtain liquid B evenly.

[0035] 2) Add liquid A dropwise to liquid B, stir evenly, and age for 2 h to obtain a transparent titanium dioxide sol.

[0036] 3) Pour the titania sol into a petri dish and dry it in the air for 24 h, and then perform a heat treatment at 450 °C for 2 h to obtain a titania mesoporous material.

[0037] The transmission electron micrographs of the prepared titanium dioxide mesoporous materials are as follows: Figure 4 . It can be seen from the figure that there are two kinds of mesoporous pores in the prepared titanium dioxide mesoporous material, one is particle packing pores and the other is micellar pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrodynamic diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com