Alginic nitric phosphate fertilizer and preparation method thereof

A technology of nitrophosphate fertilizer and alginic acid, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low content, high manufacturing cost of alginic acid, and can not meet the needs of crop growth, and achieves the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

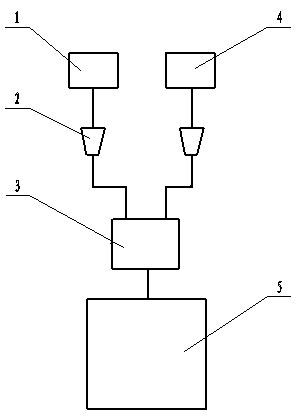

[0024] The preparation method of seaweed nitrophosphate fertilizer is to add 85-99 parts of nitrophosphate fertilizer solution to the neutralization reaction tank 3, then add 1-15 parts of alginic acid, stir and react evenly at 140°C, and then enter the evaporator feeding tank 5. Evaporate, granulate and cool after passing the test.

[0025] Such as figure 1 As shown, the seaweed nitrophosphate fertilizer, the alginic acid storage tank 1 is connected with the neutralization reaction tank 3 through the meter 2, the nitrophosphate fertilizer container 4 is connected with the neutralization reaction tank 3 through the meter 2, and the neutralization reaction tank 3 is connected with the evaporator feeding Groove 5 connection. The alginic acid storage tank 1 is filled with alginic acid, and the nitrophosphate fertilizer container 4 is filled with nitrophosphate fertilizer.

[0026] Alginic acid, CAS number: 9005-32-7, molecular formula: (C 6 h 8 o 6 )n, molecular weight: 176....

Embodiment 1

[0029] ingredient name Weight percentage content (%) total nitrogen content 26.0 Phosphorus content (in P 2 o 5 count) 12.5 Alginic acid 2 free water 0.6

[0030] Preparation of the present invention:

[0031] Add 980 kg of nitrophosphate fertilizer solution to the neutralization reaction tank 3 first, then add 20 kg of alginic acid, stir and react evenly at 140°C, enter the evaporator feeding tank 5 for evaporation, and granulate and cool after passing the test , to obtain the product of the present invention.

Embodiment 2

[0033] ingredient name Weight percentage content (%) total nitrogen content 25.5 Phosphorus content (in P 2 o 5 count) 12 Alginic acid 3 free water 0.6

[0034] Preparation of the present invention:

[0035] Add 970 kg of nitrophosphate fertilizer solution to the neutralization reaction tank 3 first, then add 30 kg of alginic acid, stir and react evenly at 140°C, enter the evaporator feeding tank 5 for evaporation, and granulate and cool after passing the test , to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com