Synthesis method of N-(2-chloride)-propionyl-glutamine

A technology of glutamine and synthetic method, which is applied in the field of synthesis of N-(2-chloro)-propionyl-glutamine, can solve the problems of low yield and long route, and achieve high product yield and simple process Feasible, simple and novel synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

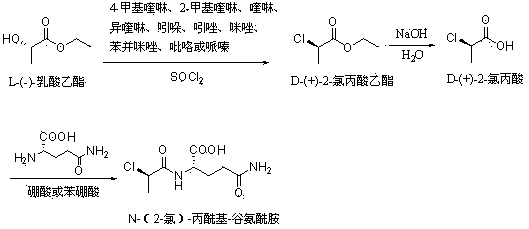

[0018] Step a, synthetic D-(+)-2-chloropropionic acid ethyl ester

[0019] Take 250 g (2.12 moles) of L-ethyl lactate in a dry three-necked bottle, o Add 2 grams of catalyst 2-methylquinoline (or 4-methylquinoline, quinoline, isoquinoline, indole, indazole, imidazole, benzimidazole, pyrrole, piperazine) below C, and then drop 262 g (2.2 moles) of thionyl chloride, keeping the temperature at 10 o Below C, after the dropwise addition, at 5 o Stir for 1 hour below C, then raise the temperature to 50 o C , stirred for 3 hours, cooled the reaction solution to 30 o C. HCl, SO2, and SOCl2 were removed under reduced pressure, and rectification was carried out after the gas was exhausted to obtain D-(+)-2-chloropropionic acid ethyl ester product with a yield of 96%. The product purity reaches 99.8%, and the optical purity reaches 99.5%.

[0020] Step b, synthesis of D-(+)-2-chloropropionic acid

[0021] Take 100 grams (0.73 moles) of ethyl D-(+)-2-chloropropionate, at 0 o St...

Embodiment 2

[0026] Step a, synthetic D-(+)-2-chloropropionic acid ethyl ester

[0027] Take 530 grams (4.45 moles) of thionyl chloride in a dry three-necked flask, o Add dropwise 500 grams (4.24 moles) of L-ethyl lactate and 4 grams of catalyst 2-methylquinoline (or 4-methylquinoline, quinoline, isoquinoline, indole, indazole, imidazole, benzene and imidazole, pyrrole, piperazine) mixture, keep the temperature at 10 o Below C, after the dropwise addition, at 5 o Stir for 1 hour below C, then raise the temperature to 50 o C , stirred for 5 hours, cooled the reaction solution to 30 o C. HCl, SO2, and SOCl2 were removed under reduced pressure, and rectification was carried out after the gas was exhausted to obtain D-(+)-2-chloropropionic acid ethyl ester product with a yield of 93%. The product purity reaches 99.5%, and the optical purity reaches 98.5%.

[0028] Step b, synthesis of D-(+)-2-chloropropionic acid

[0029] Take 500 grams (3.66 moles) of ethyl D-(+)-2-chloropropionate, at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com