Method for immobilization of lipase and its application

A technology of immobilizing lipase and fat, applied to the direction of immobilizing on or in inorganic carriers, chemical instruments and methods, silicon dioxide, etc., can solve the problems of increasing costs, waste of raw materials, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0112] The raw materials for the preparation of white carbon black and activated carbon are rice husk ash. Not specifically limited, the white carbon black and activated carbon in the examples can also come from other sources, such as commercially available.

[0113] The preparation of rice husk ash in this example: put the rice husk into the boiler, control the combustion temperature at 600-700°C, and make the rice husk be heated evenly during the combustion process, and control the combustion time within 20-60 minutes, so that the carbon content Stable between 10-30%, the organic impurities contained in the rice husk are removed with the boiler induced draft system, and the rice husk ash discharged from the bottom of the fire grate is the raw material when the carbon content is in the range of 15%-25%. The rice husk ash is sieved through a 1-5 mm linear sieve to remove impurities such as brown rice stones to obtain the raw material of rice husk ash for preparing white carbon...

Embodiment 1

[0119] Embodiment 1: prepare white carbon black and activated carbon from rice husk ash

[0120] 1. Preparation of activated carbon 1: Weigh 300g of rice husk ash raw material, 96g of sodium hydroxide, add to the autoclave, then add 900mL of water, the reaction pressure is controlled at 4kg, the reaction time is 4h, filter and wash to obtain the filtrate and filter cake , the obtained filtrate is water glass, and the modulus of water glass filtrate is 2.5. Add one-fold amount of water to the obtained filter cake and mix, control the carbon content at about 15%, stir and heat to 50°C, and flow into it at a flow rate of 10m 3 Add dilute sulfuric acid with a concentration of 10% at a speed of / h, adjust the pH of the system to 3.5 within 10-30 minutes, filter and wash, and obtain activated carbon 1 after drying.

[0121]Preparation of white carbon black 1: first add 300g of water glass filtrate obtained by filtration into the reactor with a modulus of 2.5 and a specific gravity o...

Embodiment 2

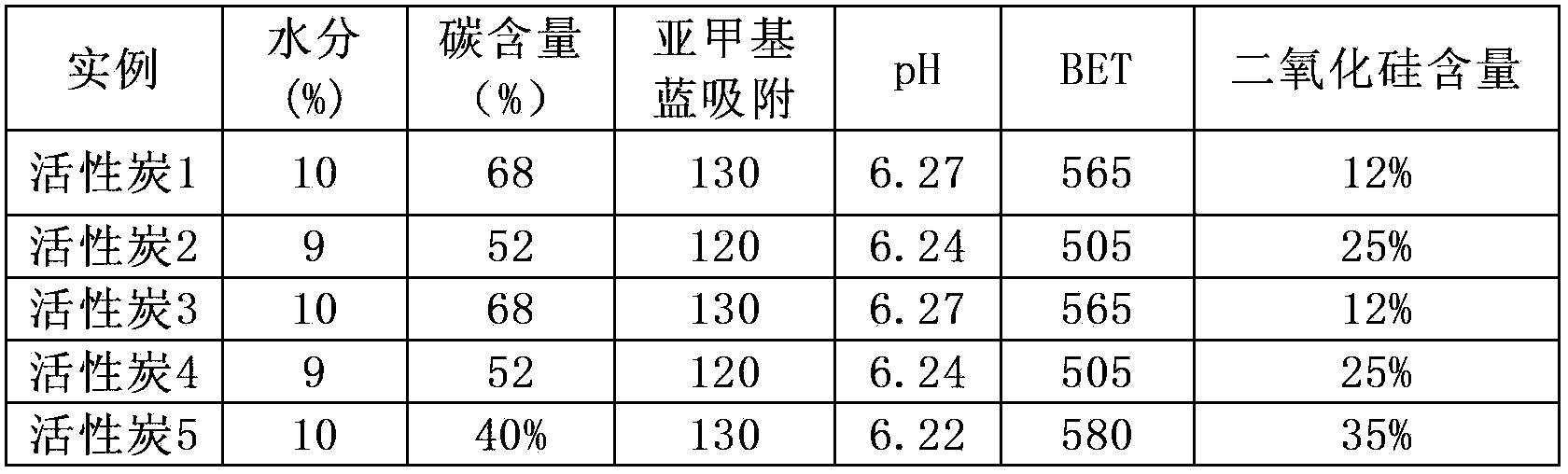

[0129] Embodiment 2: the detection embodiment of white carbon black and activated carbon

[0130] The gac prepared in Example 1 and white carbon black are detected by national detection method GB / T12496-1999 and HG / T3061-1999, and the results are as follows:

[0131] Table 1 Detection index of activated carbon

[0132]

[0133] Note: BET is specific surface area, unit m 2 / g.

[0134] It can be shown from the detection data that the activated carbon prepared by the method of the present invention also contains silicon dioxide, and the obtained product is a mixture of activated carbon and silicon dioxide.

[0135] Table 2 Detection index of white carbon black

[0136] example

[0137] Note: BET is specific surface area, unit m 2 / g, DBP is the oil absorption value, and the unit is weight%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com