Step-down converter

A converter and step-down technology, applied to output power conversion devices, instruments, DC power input conversion to DC power output, etc., can solve the problem of increasing chip cost and off-chip area, power consumption, area, and structure Complicated problems, to achieve the effect of saving power consumption, suppressing overshoot current, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

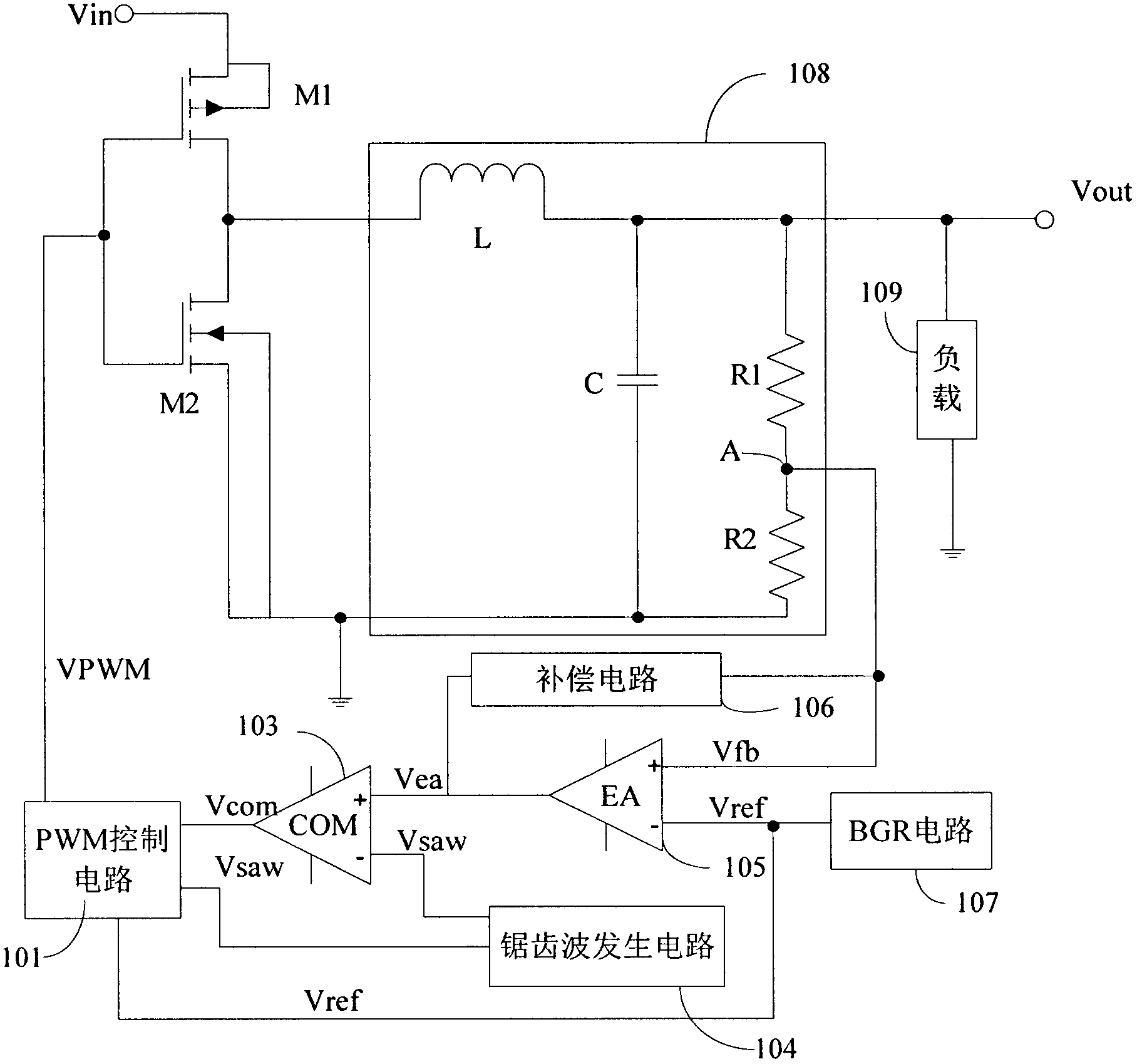

[0026] The invention provides a step-down converter for portable medical equipment or handheld electronic products. The step-down converter is a low-power consumption and high-efficiency step-down (buck) DC-DC converter with a soft start circuit.

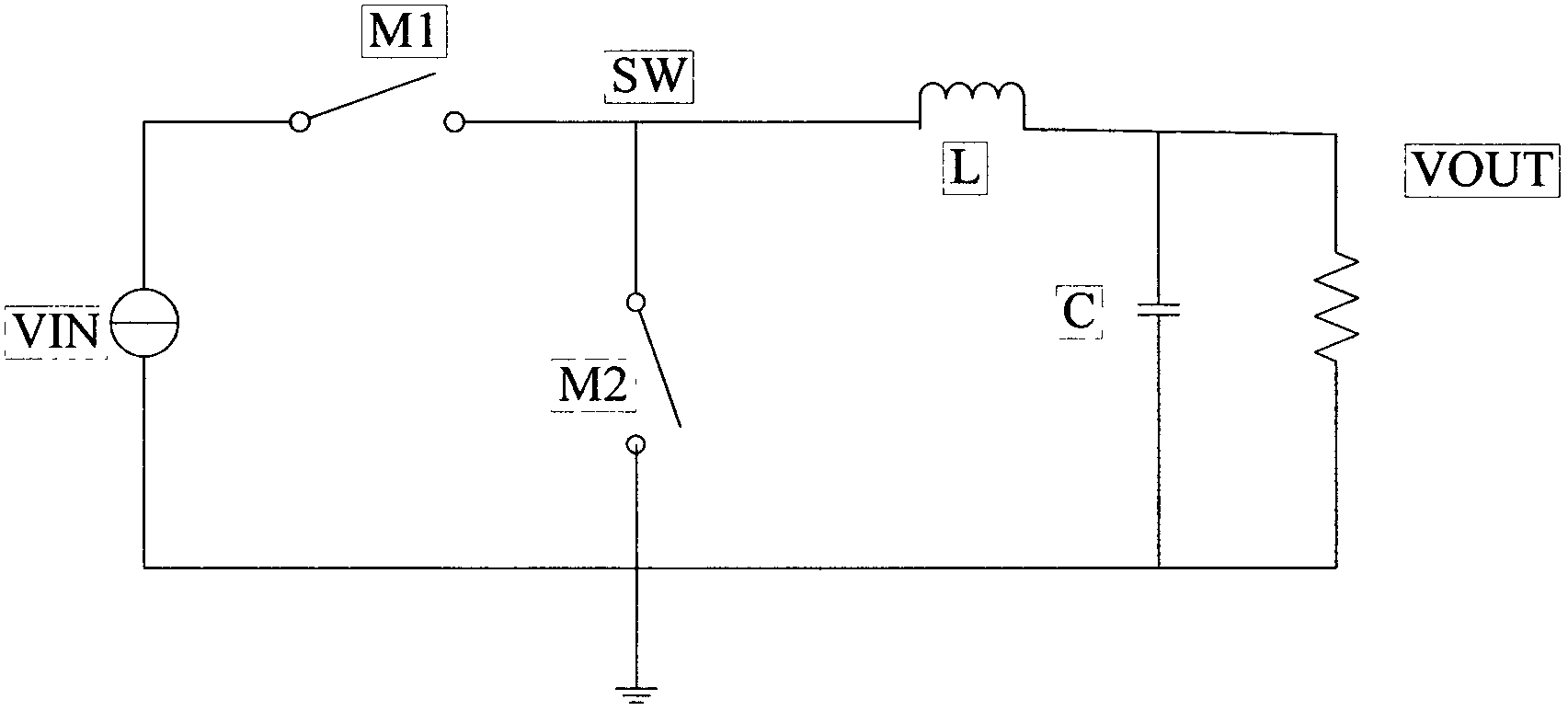

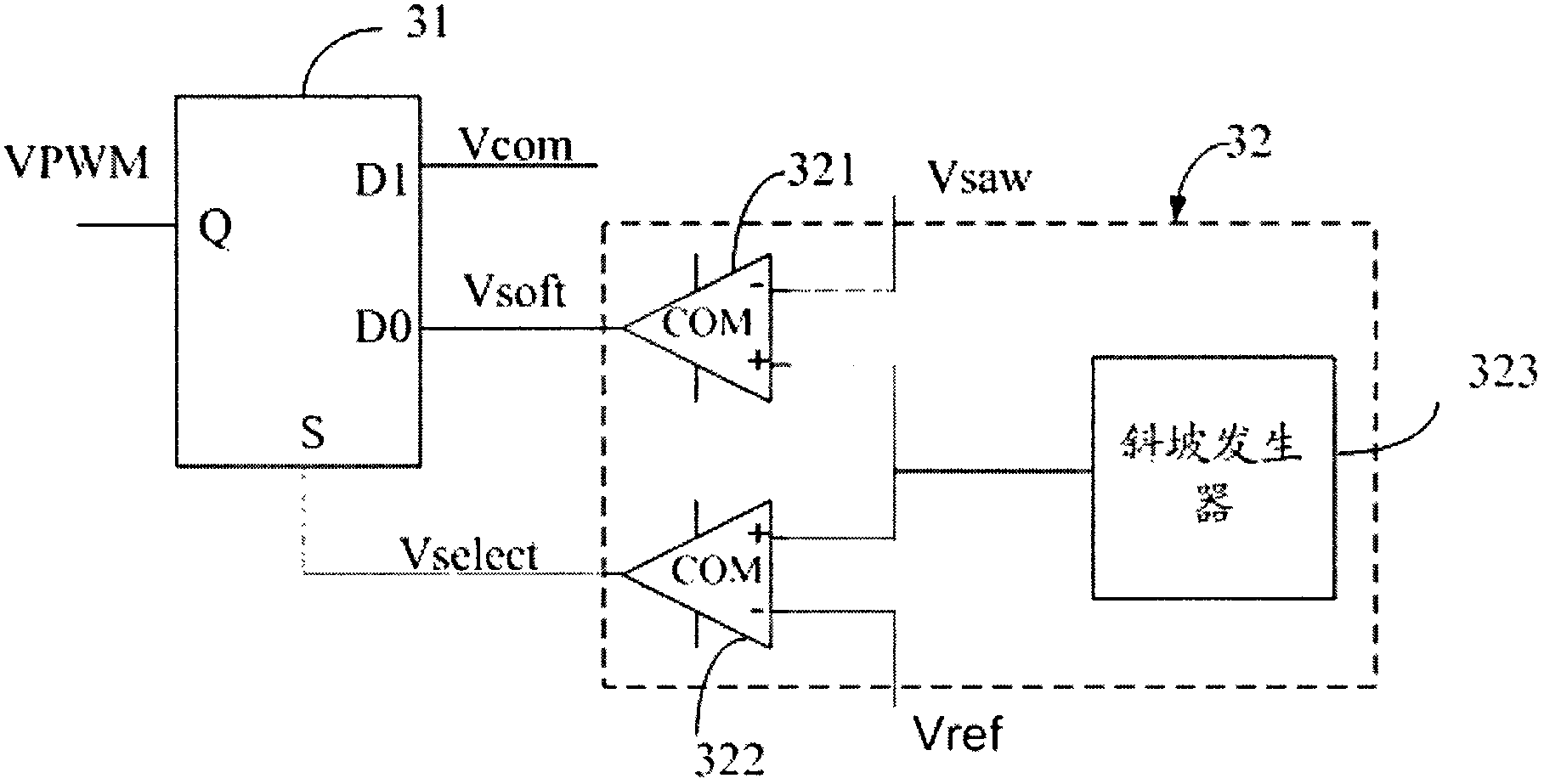

[0027] Such as figure 1Shown is the circuit structure diagram of the step-down converter of the preferred embodiment of the present invention. The buck converter described in this embodiment includes a switching power tube M1, a rectifier tube M2, a pulse width modulation (PWM, pulse width modulation) control circuit 101, a first voltage comparator (COM, comparator) 103, and a sawtooth wave generator. Circuit (sawtooth wave generator) 104, error amplifier (EA, error amplifier) 105, compensation (compensation) circuit 106, bandgap reference (BGR, band-gap reference) circuit 107, composed of inductor L, capacitor C, voltage divider resistor R1 and R2 form the power supply module 108. The power supply module 108 described in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com